How to assemble a solar power generation system | NenPower

To assemble a solar power generation system, one must follow a series of steps that include understanding the components, site assessment, system design, and actual

Get Price

How to assemble a solar power generation system

To assemble a solar power generation system, one must follow a series of steps that include understanding the components, site assessment,

Get Price

What are the tricks for assembling solar panels?

The assembly of solar panels is an intricate process that requires attention to detail, adherence to safety protocols, and a comprehensive

Get Price

Fundamental study related to the development of

1 INTRODUCTION Renewable energy is the future for sustainable development and nature friendly co-existence as human species. One of the

Get Price

Solar Panel Manufacturing: Sunlight to Power

6 days ago· As the world moves towards cleaner energy, solar panels are in demand. let''s know about how can you make solar panels? This article will

Get Price

How To Assemble Solar Panel System?

Assembling a solar panel system requires careful planning, the right components, tools, and adherence to safety protocols. This guide

Get Price

Oando, REA to build 1.2GW solar module assembly plant in Nigeria

This recent announcement comes after the groundbreaking ceremony for a solar module assembly plant held in Enugu, a southeastern state, last July. In a separate

Get Price

Satellite Solar Panels

Sparkwing Satellite Solar Panels On this page we''ll explain the basics of satellite solar panels, how to find the perfect power match for your satellite, which

Get Price

Solar Panel Manufacturing: Sunlight to Power

6 days ago· As the world moves towards cleaner energy, solar panels are in demand. let''s know about how can you make solar panels? This article will guide you through the production of

Get Price

How to assemble solar photovoltaic power generation

ASSEMBLY PROCESS OF SOLAR PHOTOVOLTAIC SYSTEMS: The assembly of solar photovoltaic (PV) power generation systems involves several crucial steps: 1.

Get Price

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting, assembling, and packaging

Get Price

Processes for the assembly and production of solar panels

Solar panels convert light into power, converting energy everywhere. However making solar panels requires complex material structures and production processes, read this article to

Get Price

How does solar photovoltaic power generation work? | NenPower

2. SOLAR PANEL ASSEMBLY AND SYSTEM CONFIGURATIONS Solar panels are essentially an assembly of multiple photovoltaic cells connected together in a structured

Get Price

Photovoltaics

The photovoltaic effect is commercially used for electricity generation and as photosensors. A photovoltaic system employs solar modules, each comprising a number of solar cells, which

Get Price

How Are Solar Panels Made Step by Step

Here, we''ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into powerful photovoltaic modules.

Get Price

How Are Solar Panels Made Step by Step

Here, we''ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into

Get Price

Solar power generation panel assembly

Panel Assembly In the panel assembly phase,solar cellsare interconnected in a series configuration to achieve the desired voltage and current characteristics. The interconnected

Get Price

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Get Price

2,118 Solar Panels Process Images, Stock Photos & Vectors

Find Solar Panels Process stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures

Get Price

Processes for the assembly and production of solar

Solar panels convert light into power, converting energy everywhere. However making solar panels requires complex material structures and production

Get Price

How To Assemble Solar Panel System?

Assembling a solar panel system requires careful planning, the right components, tools, and adherence to safety protocols. This guide provides step-by-step instructions for

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

6 FAQs about [Power generation solar panel assembly]

What is the solar panel manufacturing process?

The solar panel manufacturing process involves several crucial steps, including silicon purification, ingot creation, wafer slicing, solar cell fabrication, and panel assembly. Solar PV modules consist of solar cells, glass, EVA, backsheet, and a metal frame, all of which are carefully integrated during the manufacturing process.

How do you make a solar panel?

Here, we’ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into powerful photovoltaic modules. This process includes melting silicon ingots to creating the final solar panels. Leading the charge in making these clean energy solutions is Fenice Energy from India.

How a photovoltaic module is assembled?

The assembly of photovoltaic modules consists of a series of consecutive operations that can be performed by automatic machines dedicated to optimizing the single production phases that transform the various raw material in a finished product.

How are solar panels assembled?

Solar Panel Assembly Once the individual solar cells have been tested, they are interconnected using metal contacts to form a solar panel. The cells are arranged in rows and columns and are soldered together. 8. Lamination

What is a solar PV module?

Solar PV modules consist of solar cells, glass, EVA, backsheet, and a metal frame, all of which are carefully integrated during the manufacturing process. Different types of solar panels, such as monocrystalline, polycrystalline, and thin-film, have slightly varying production methods.

What are the components of a solar panel system?

A: A solar panel system typically includes solar panels, an inverter, mounting/racking system, wiring, and optionally, batteries and a monitoring system. 2: What tools are required for installing a solar panel system?

More related information

-

Photovoltaic power generation and solar panel shading

Photovoltaic power generation and solar panel shading

-

Hungary container solar panel power generation

Hungary container solar panel power generation

-

Middle East Solar Panel House Photovoltaic Power Generation

Middle East Solar Panel House Photovoltaic Power Generation

-

Solar panel photovoltaic power generation area

Solar panel photovoltaic power generation area

-

Solar panel power generation manufacturers

Solar panel power generation manufacturers

-

Power generation solar panel container

Power generation solar panel container

-

Bhutan Solar Panel Power Generation Enterprise

Bhutan Solar Panel Power Generation Enterprise

-

Power Generation Solar Panel Photovoltaic Project Introduction

Power Generation Solar Panel Photovoltaic Project Introduction

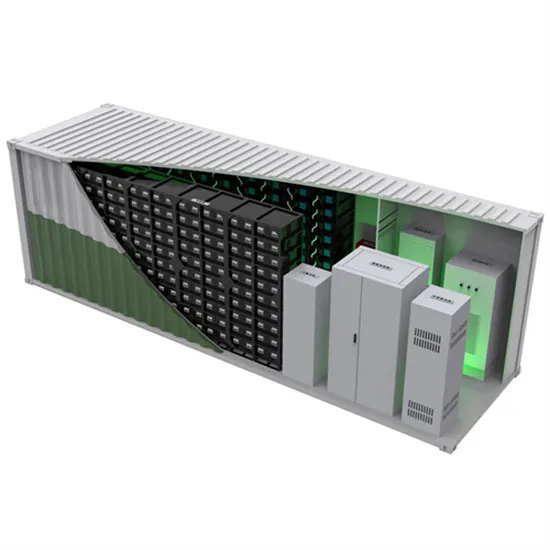

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.