What is the pump inverter used for and when should it

The pump inverter saves energy and optimizes the operation of the pump. How does it work and when to install it?

Get Price

Boyd''s Liquid Cooling Solutions for Electric Vehicles

Inverter power density varies by localized high power density heat sources requiring local hot spot heat spreading and cooling. Inverters must also be cooled below critical temperatures to

Get Price

Integrated Vehicle Thermal Management – Combining Fluid

Thermal requirements for ESS Additional thermal components result in higher costs Multiple cooling loops lead to reduced range due to Increased weight Energy required to meet thermal

Get Price

Home Energy Storage will Enter the "Liquid Cooling

It uses a circulating water pump to drive the cooling liquid convection to directly dissipate heat to the battery cells. The method is

Get Price

Eight major differences between air cooling and liquid cooling in

Air cooling and liquid cooling are two commonly used heat dissipation methods in energy storage systems. When choosing a heat dissipation method, factors such as the actual power of the

Get Price

Drive Train Cooling Options for Electric Vehicles

In the case of Inverter, two phase cooling system based on heat pipes was designed to handle hot spots arising from high heat flux (~100 W/cm 2)–for liquid cooling and

Get Price

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get Price

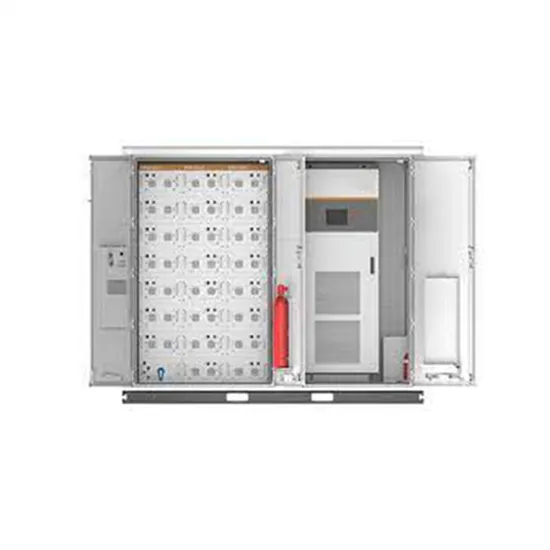

125KW/233KWh Liquid-Cooling Energy Storage Integrated

The battery container adopts an energy cube structure, and each energy cube is equipped with a water cooler, inverter, and fire control system; the battery module meets the 15-minute quick

Get Price

How liquid-cooled technology unlocks the potential of energy storage

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. "If you have a thermal runaway of a cell, you''ve got this massive heat

Get Price

Why More and More Energy Storage Companies Are Choosing

Explore the benefits of liquid cooling technology in energy storage systems. Learn how liquid cooling outperforms air cooling in terms of efficiency, stability, and noise reduction,

Get Price

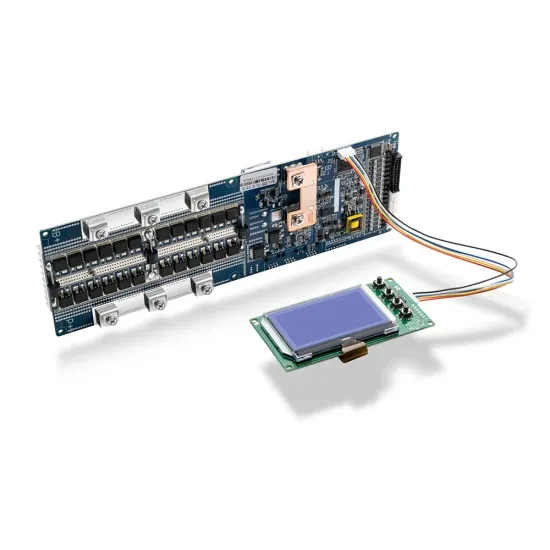

Introduction to inverter coolant and how to choose –

This article dicusses the concept of inverter coolant, different cooling methods, types of inverter coolant, selection criteria, and effective

Get Price

Liquid Cooling in Energy Storage | EB BLOG

By employing high-volume coolant flow, liquid cooling can dissipate heat quickly among battery modules to eliminate thermal runaway risk quickly – and significantly reducing

Get Price

What is a Water-Cooled Energy Storage Module? Your Guide to

Why Your Energy Storage System Needs a "Cool Friend" (and No, We Don''t Mean a Penguin) Imagine your smartphone overheating during a video call – now picture that

Get Price

Air-Cooled vs. Liquid-Cooled Energy Storage Systems

An energy storage cooling system is a thermal management solution used to maintain safe and optimal operating temperatures in lithium battery energy storage systems (ESS). Efficient

Get Price

Air Cooling vs. Liquid Cooling: The Ultimate Energy

Explore the battle of cooling methods for energy storage! Uncover whether air or liquid cooling reigns supreme for your ESS needs. Click to learn

Get Price

Home Energy Storage will Enter the "Liquid Cooling Era"?

It uses a circulating water pump to drive the cooling liquid convection to directly dissipate heat to the battery cells. The method is controllable, and not affected by external

Get Price

The Unsung Hero of Energy Storage: Why Water Pumps Are

In 2023 alone, liquid-cooled储能 systems accounted for 62% of new industrial installations, and guess what makes them tick? That''s right – pumps that could fill an Olympic

Get Price

Liquid Cooling in Energy Storage | EB BLOG

By employing high-volume coolant flow, liquid cooling can dissipate heat quickly among battery modules to eliminate thermal runaway

Get Price

Water Pump Inverter | Pump Inverter | 3P Technik UK Ltd

Our range of inverters are compact, highly efficient, quiet and a reliable solution for domestic, and light commercial applications. We have air or water cooled versions with pump control from

Get Price

How liquid-cooled technology unlocks the potential of

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. "If you have a thermal runaway of a

Get Price

Water Cooled Power Converter GRW6

Water Cooled Power Converter GRW6 AC/DC water cooled power converter GRW6 is used in all applications that require high power with low voltage power supply, maintaining a small size.

Get Price

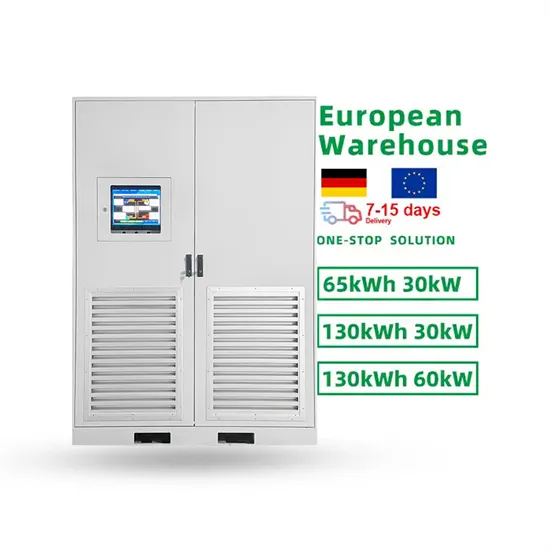

Sungrow''s New Liquid Cooled Energy Storage

Sungrow''s Liquid Cooled Energy Storage System Better Supplies the BESS Plants Noticeably, Sungrow''s new liquid cooled energy storage system, the

Get Price

Cooling systems for utility-scale solar and storage inverters

In demanding applications such as solar and storage power inverters that suffer from high temperatures and handle high power, active liquid cooling is the option that provides the best

Get Price

373kWh Liquid Cooled Energy Storage System

The MEGATRONS 373kWh Battery Energy Storage Solution is an ideal solution for medium to large scale energy storage projects. Utilizing Tier 1 LFP battery cells, each battery cabinet is

Get Price

How Can Liquid Cooling Revolutionize Battery Energy

With the rapid advancement of technology and an increasing focus on energy efficiency, liquid cooling systems are becoming a game-changer across

Get Price

Why More and More Energy Storage Companies Are Choosing Liquid Cooling

Explore the benefits of liquid cooling technology in energy storage systems. Learn how liquid cooling outperforms air cooling in terms of efficiency, stability, and noise reduction,

Get Price

6 FAQs about [Does liquid-cooled energy storage require a water pump inverter ]

Are liquid cooled battery energy storage systems better than air cooled?

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. “If you have a thermal runaway of a cell, you’ve got this massive heat sink for the energy be sucked away into. The liquid is an extra layer of protection,” Bradshaw says.

Do inverters need to be cooled?

Inverters must also be cooled below critical temperatures to optimize vehicle performance. A cooling system must be tailored for optimal cooling of batteries and various inverters from the same system, coolant, and cooling loop for space, weight, and cost savings.

What is a liquid EV inverter?

Liquid systems offer the most eficient cooling and flexibility Example of an EV inverter – with cut out. in design to meet the requirements of both the battery and inverters within one central thermal system. Utilizing one optimized loop enables the best possible performance for every system component as well as savings in weight, space and cost.

What is the difference between air cooled and liquid cooled energy storage?

The implications of technology choice are particularly stark when comparing traditional air-cooled energy storage systems and liquid-cooled alternatives, such as the PowerTitan series of products made by Sungrow Power Supply Company. Among the most immediately obvious differences between the two storage technologies is container size.

Do high heat flux inverters work together?

Higher heat flux inverters necessary to make electrical power viable for operating the vehicle add another layer of complexity to necessary heat rejection systems. Batteries and high heat flux inverters work together although their cooling requirements can be quite different.

Why is liquid cooling better than air?

Liquid-cooling is also much easier to control than air, which requires a balancing act that is complex to get just right. The advantages of liquid cooling ultimately result in 40 percent less power consumption and a 10 percent longer battery service life. The reduced size of the liquid-cooled storage container has many beneficial ripple effects.

More related information

-

Photovoltaic energy storage water pump inverter

Photovoltaic energy storage water pump inverter

-

Water pump inverter piston gravity energy storage device

Water pump inverter piston gravity energy storage device

-

What are the basic functions of an energy storage inverter

What are the basic functions of an energy storage inverter

-

Does photovoltaic energy storage require batteries

Does photovoltaic energy storage require batteries

-

Samoa PV Energy Storage 50kw Inverter Quote

Samoa PV Energy Storage 50kw Inverter Quote

-

Uruguayan Photovoltaic Energy Storage Inverter Company

Uruguayan Photovoltaic Energy Storage Inverter Company

-

Low voltage three-phase energy storage inverter

Low voltage three-phase energy storage inverter

-

What inverter should be used in energy storage systems

What inverter should be used in energy storage systems

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.