Thermodynamic cycles for solar thermal power plants:

Abstract Solar thermal power plants for electricity production include, at least, two main systems: the solar field and the power block.

Get Price

Analysis of low‐temperature pumped thermal energy storage

A two-zone water storage tank with a storage temperature of 115°C is used as thermal energy storage. For discharge, an Organic Rankine Cycle (ORC) and, alternatively, a

Get Price

Storage Fluid

Storage fluid selection Water has been widely deployed for thermal energy storage—typically supplying hot or cold thermal energy to domestic loads. For electricity storage applications,

Get Price

6 Low-temperature thermal energy storage

Sensible storage of heat and cooling uses a liquid or solid storage medium witht high heat capacity, for example, water or rock. Latent storage uses the phase change of a material to

Get Price

SCO2 Power Cycles

The sCO2 Team draws on the resources of DOE offices to achieve the highest efficiencies offered by the sCO2 Brayton cycle technology. Power cycles

Get Price

Performance comparison of three supercritical CO2 solar thermal power

Compressed CO 2 energy storage can be temperature independent, so in this paper, based on the characteristics of the solar sCO 2 Brayton cycle system and the

Get Price

Passive low temperature heat sources organic working fluid power

Compared with the prior technology, the present invention has reliable performance, and is operated by heating and evaporating of the working fluid in a closed space to achieve

Get Price

Low-Temperature and Co-Produced Resources Fact Sheet

Increasingly, low-temperature resources below 150°C—once reserved for direct-use applications such as heating, greenhouses, fisheries, and mineral recovery—can now be used for power

Get Price

Pumped Thermal Electricity Storage with Supercritical CO2

The temperature difference between the storage fluid and power cycle working fluid has a more significant effect on sCO2 cycles than ideal-gas cycles. sCO2 cycles transfer large quantities

Get Price

Working Fluid Selection for Low Temperature Solar

PDF | On Oct 5, 2010, Gang Pei and others published Working Fluid Selection for Low Temperature Solar Thermal Power Generation with Two-Stage Collectors

Get Price

Overview of working fluids and sustainable heating, cooling and

Study results showed that there is a rapid development in heating, cooling and power generation technologies those use water/air as working fluid. These technologies

Get Price

6 Low-temperature thermal energy storage

By decoupling heating and cooling demands from electricity consumption, thermal storage systems allow the integration of greater shares of variable renewable generation, such as

Get Price

Overview of working fluids and sustainable heating, cooling and power

Study results showed that there is a rapid development in heating, cooling and power generation technologies those use water/air as working fluid. These technologies

Get Price

8.5. Thermal Energy Storage | EME 812: Utility Solar

8.5. Thermal Energy Storage Different types of fluids are commonly used for storing thermal energy from concentrating solar power (CSP) facilities. CSP

Get Price

Comparative study of waste heat steam SRC, ORC and S-ORC power

For Steam Rankine Cycle (SRC), Organic Rankine Cycle (ORC) and Steam-Organic Rankine Cycle (S-ORC) power systems, in this paper, mathematical models are

Get Price

Analysis of low‐temperature pumped thermal energy

A two-zone water storage tank with a storage temperature of 115°C is used as thermal energy storage. For discharge, an Organic Rankine Cycle

Get Price

Passive low temperature heat sources organic working fluid

Compared with the prior technology, the present invention has reliable performance, and is operated by heating and evaporating of the working fluid in a closed space to achieve

Get Price

Simultaneous optimization of system structure and working fluid

He, S; Chang, H; Zhang, X; Shu, S; Duan, C 2015: Working fluid selection for an Organic Rankine Cycle utilizing high and low temperature energy of an LNG engine Applied Thermal

Get Price

Performance Evaluation and Working Fluid Screening

Traditional working fluids used in direct vapor generation for solar organic Rankine cycle (DVG-ORC) systems have a high global warming

Get Price

Thermodynamic analysis of pump thermal energy storage system

To investigate the criteria for selecting working fluids in biomass power plants coupled with pump thermal energy storage (PTES) system, two system models, HPO (heat

Get Price

Economic Long-Duration Electricity Storage by Using Low

The ENDURING system comprises high-temperature, low-cost particle thermal energy storage coupled with an advanced pressurized fluidized bed heat exchanger (PFB HX)

Get Price

Thermodynamic performance of organic rankine cycle based

Renewable energy sources like wind and solar are inherently intermittent and unpredictable; energy storage systems address this by storing surplus power and releasing it

Get Price

Economic Long-Duration Electricity Storage by Using Low-Cost

The National Renewable Energy Laboratory team will develop a high-temperature, low-cost thermal energy storage system using a high-performance heat exchanger and

Get Price

Working Fluid Selection for Low Temperature Solar Thermal

Among many well-proven technologies, the ORC is one of the most favorable and promising ways for low-temperature applications. In comparison to water, organic fluids are advantageous

Get Price

FEASIBILITY OF VARIOUS SMALL-SCALE LOW

This study evaluates and compares several candidates for the conversion of low-temperature solar thermal energy into power and examines their technical feasibility and thermodynamic

Get Price

Thermal Energy Storage

The most common Cool TES energy storage media are chilled water, other low-temperature fluids (e.g., water with an additive to lower freezing point), ice, or some other phase change material.

Get Price

6 FAQs about [Low-temperature working fluid energy storage power generation]

Can low-temperature resources be used for power generation?

Increasingly, low-temperature resources below 150°C—once reserved for direct-use applications such as heating, greenhouses, fisheries, and mineral recovery—can now be used for power generation under the right conditions.

How do thermal energy storage systems work?

Thermal energy storage (TES) systems can help store energy on the timescales of these fluctuations. TES units are integrated into pumped thermal energy storage (PTES) systems, which operate through three subprocesses: charging, storage and discharging.

Can 'long-term sustainable' fluids be used in power and air conditioning cycles?

This could be achieved with innovative power, air conditioning and refrigeration cycles utilising ‘long-term sustainable’ (LTS) fluids, especially air, water and CO 2. In the article we provide a rational approach to the future use of working fluids based on our interpretation of the available technical evidence.

Can low-grade heat reduce energy consumption-fossil fuel dependency?

CHP is a proven technology with technical, economic and environmental benefits using the low-grade heat for both electrical and thermal power supply. Authors agree that the key to reduce future energy consumption-fossil fuel dependency lies on maximum utility from low-grade heat.

Are volatile fluids the future of cooling & power generation?

From our point of view, volatile fluids will continue to play major roles in cooling and power generation in the future. However, presented new technologies using air/water couple will be the key to optimise energy efficiency–safety also optimal usage of volatile fluids with minimal environmental impact.

Can a two-zone water storage tank be used as thermal energy storage?

A two-zone water storage tank with a storage temperature of 115°C is used as thermal energy storage. For discharge, an Organic Rankine Cycle (ORC) and, alternatively, a transcritical CO 2 heat engine are investigated. The considered concepts are modelled and simulated as stationary processes using the EBSILON Professional software.

More related information

-

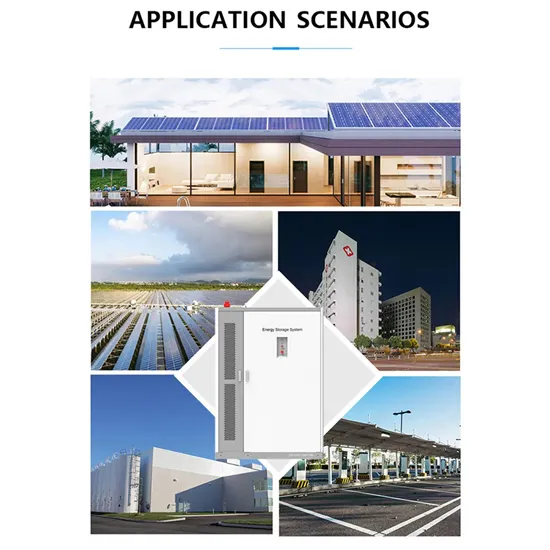

Energy storage and grid-connected power generation

Energy storage and grid-connected power generation

-

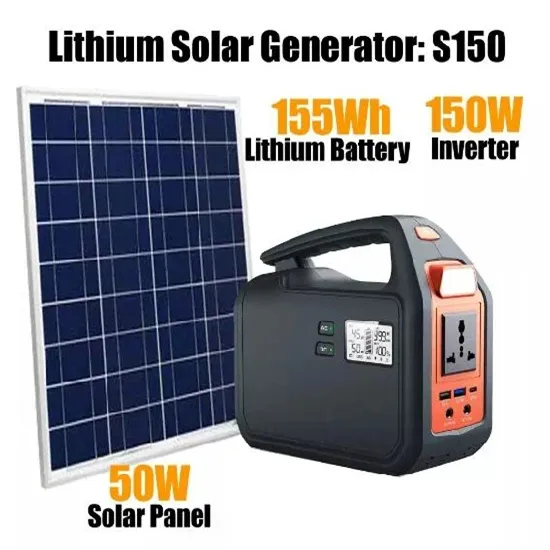

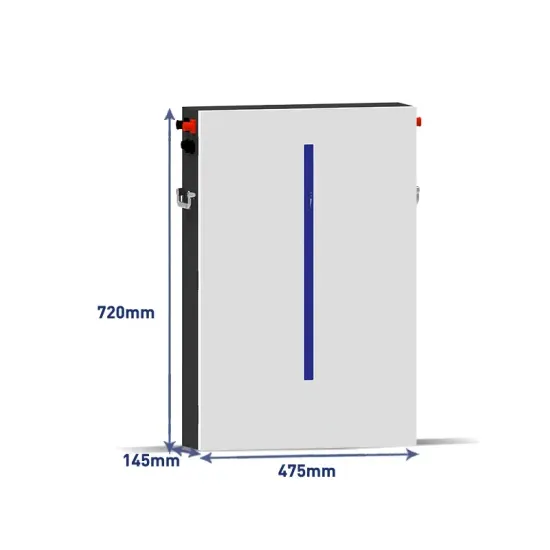

Energy storage battery cabinet base station power generation type

Energy storage battery cabinet base station power generation type

-

Guatemala Photovoltaic Energy Storage Power Generation Project

Guatemala Photovoltaic Energy Storage Power Generation Project

-

Ecuadorian Photovoltaic Power Generation and Energy Storage Systems

Ecuadorian Photovoltaic Power Generation and Energy Storage Systems

-

Which energy storage photovoltaic power generation company is best in North America

Which energy storage photovoltaic power generation company is best in North America

-

Gabon Energy Storage Power Generation

Gabon Energy Storage Power Generation

-

Huawei Finland Photovoltaic Power Generation and Energy Storage Project

Huawei Finland Photovoltaic Power Generation and Energy Storage Project

-

Argentina Carport Photovoltaic Power Generation Energy Storage Cabinets

Argentina Carport Photovoltaic Power Generation Energy Storage Cabinets

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

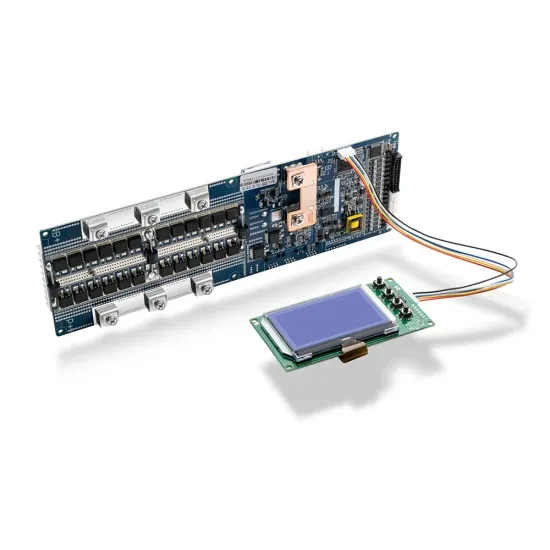

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.