9. Inverter Settings

To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be set at least

Get Price

Tweaking Your Power Inverter, Get More Bang for the Buck

This instructable is a guide for repairing/increasing the output power of a simple dc-AC power converter (this instructable address the boost dc-dc converter based power inverter).

Get Price

4. Configuration

The dynamic cut off algorithm in the inverter can not take those other loads into consideration and will shut down the Inverter too early with an under voltage alarm.

Get Price

Inverter too high output voltage than normal, problem?

It has a detection voltage range of 180V to 260V and turns on when the electricity voltage is higher or lower when it is set to UPS Mode. Its detection mode is higher (they do not

Get Price

CSM_Inverter_TG_E_1_1

Without an inverter, the AC motor would operate at full speed as soon as the power supply was turned ON. You would not be able to control the speed, making the applications for the motor

Get Price

Voltage Control Techniques for Inverters:

The voltage waveform has a high harmonic content at lower frequencies and the utilization of the thyristors is very poor. The technique involves two inverters, making it costly for low power

Get Price

difference between PV input and MPPT range

this is my solar inverter datasheet i don''t get the difference between the MPPT and The PV input voltage my each pv in series should equal to 500v? or to 425?

Get Price

Changing inverter voltage output?

Modern switching regulated power supplies will still pull about the same power by pulling less current at the higher voltage, but an old style linear regulator will have to drop the

Get Price

How Does Input Voltage Affect a Grid-Tie Inverter?

Just try to match the string voltage to the rated operating voltage of the inverter, you will have the highest efficiency, and the maximum voltage

Get Price

Inverter Basics | inverter

Advantages Enhanced Reliability: With a system featuring a larger number of smaller inverters, the failure of one inverter results in the loss of

Get Price

Understanding inverter voltage

An abnormally high inverter output voltage may indicate a malfunction in the voltage regulation circuit. Addressing this issue promptly is crucial to prevent potential damage

Get Price

AKX00057-1

High-side power supplies can be divided into two types: 1) a bootstrap power supply that uses the switching of the main inverter and 2) a charge pump that uses the switching of a

Get Price

Can Inverter Run Air Conditioner

While an inverter can technically run an air conditioner, it is generally not recommended due to several limitations. Inverters are primarily

Get Price

CHAPTER 2

link converter. Inverters can be broadly classified into two types, voltage source and current source inverters. A voltage–fed inverter (VFI) or more generally a voltage–source inverter

Get Price

Understanding Inverter Voltage: Definition, Functions,

This is because the inverter is a device that changes the electric current itself, so the higher the voltage contained in the inverter, the greater

Get Price

Tweaking Your Power Inverter, Get More Bang for the

This instructable is a guide for repairing/increasing the output power of a simple dc-AC power converter (this instructable address the boost dc-dc converter

Get Price

Voltage Control Methods of Inverter – PWM Technique

The output voltage of an inverter can be adjusted by employing the control technique within the inverter itself. This control technique can be accomplished by the

Get Price

How Does Input Voltage Affect a Grid-Tie Inverter?

Just try to match the string voltage to the rated operating voltage of the inverter, you will have the highest efficiency, and the maximum voltage will not be exceeded at the

Get Price

Comparing Carrier-Based PWM Techniques in High

This article explores the potential of carrier-based pulse width modulation techniques such as sawtooth, triangular, and sinusoidal, and

Get Price

Exceeding Inverter Limits

Isn''t that sketch a 2s4p setup? That should be plenty fine for 66v panels on a 250v controller, unless it''s one of those high voltage needs 120+ volts to start AIO''s that are getting

Get Price

Maximizing Energy Efficiency: How to Use an Inverter

Most inverters allow you to adjust the output voltage to match your load requirements. Reducing the output voltage can help improve efficiency and

Get Price

Inverter too high output voltage than normal, problem?

Hi, One of the inverter of my school generating peak AC voltage of around 280V. My country''s standard mains voltage is around 220 to 230V AC. I have noticed that some cell

Get Price

Voltage Control Methods of Inverter – PWM Technique

The voltage waveform has a high harmonic content at lower frequencies and the utilization of the thyristors is very poor. The technique involves two inverters,

Get Price

Variable-frequency drive

In variable- torque applications suited for Volts-per-Hertz (V/Hz) drive control, AC motor characteristics require that the voltage magnitude of the inverter''s

Get Price

How to adjust the output voltage of an Inverter Solar 12v 220v?

As the battery discharges, its voltage drops, which may lead to a decrease in the inverter''s output voltage. By adjusting the output voltage, you can optimize the power transfer and improve the

Get Price

Understanding Inverter Voltage: Definition, Functions, Type, and

This is because the inverter is a device that changes the electric current itself, so the higher the voltage contained in the inverter, the greater the performance that will be

Get Price

6 FAQs about [Can the inverter voltage be adjusted higher ]

How to control AC voltage in an inverter?

Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

What causes low output inverter voltage?

Low output inverter voltage can stem from issues such as a weak battery, loose connections, or internal faults. Thoroughly troubleshooting these aspects can help identify and rectify the cause of low output inverter voltage. Why is inverter output voltage so high?

Why does a string inverter have a 230V output?

The reason for this starts from the principle of the power inverter. For the DC-DC-BOOST circuit of the string inverter, the DC voltage needs to be boosted and stabilized to a certain value (this is called the DC bus voltage) before it can be converted to AC power. As to the 230V output, its DC bus voltage should be about 360V.

How a voltage control inverter helps in achieving voltage variation?

In the case of variable speed drives, inverters with voltage control help in achieving voltage variation. Voltage control of inverters is employed in order to compensate for changes in input dc voltage.

What happens if inverter voltage is too high?

Exceeding the specified maximum input voltage for an inverter can lead to various issues. These include overheating, potential damage to internal components, and the risk of a malfunction. To mitigate these risks, manufacturers often incorporate overvoltage protection mechanisms into their inverters. How do I choose an inverter voltage?

Why is inverter voltage important?

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter voltage is essential for anyone seeking a reliable and efficient power supply.

More related information

-

Is it better if the inverter discharges a higher voltage

Is it better if the inverter discharges a higher voltage

-

Can the inverter voltage be adjusted if it is high

Can the inverter voltage be adjusted if it is high

-

Inverter wide voltage regulation

Inverter wide voltage regulation

-

Power supply voltage inverter function

Power supply voltage inverter function

-

What is the appropriate current and voltage of the inverter

What is the appropriate current and voltage of the inverter

-

70kw inverter voltage level

70kw inverter voltage level

-

Thailand voltage stabilizer inverter price

Thailand voltage stabilizer inverter price

-

50kw inverter maximum AC voltage

50kw inverter maximum AC voltage

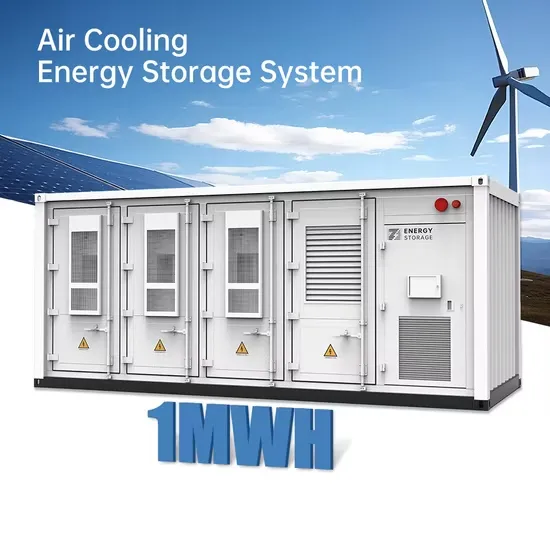

Commercial & Industrial Solar Storage Market Growth

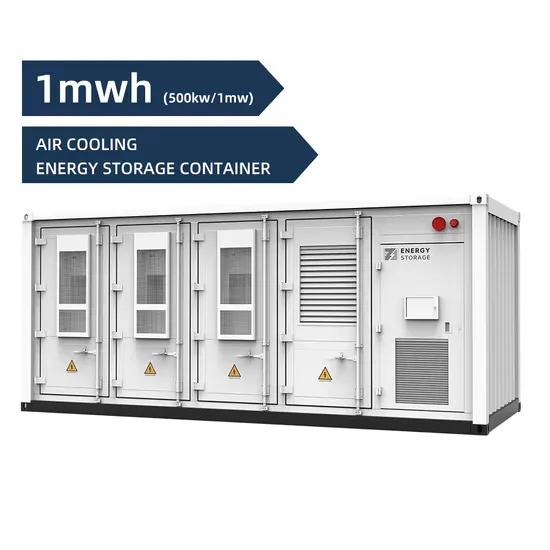

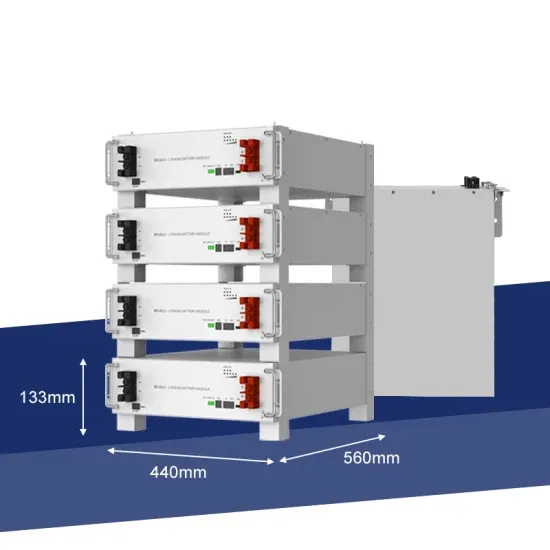

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

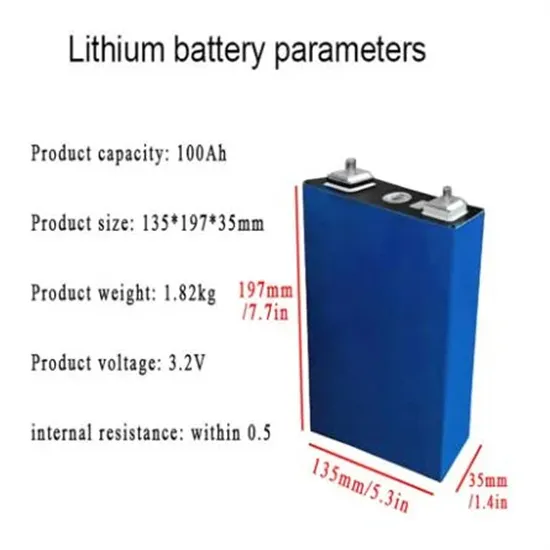

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.