Tower Erection for Transmission Lines | MECHHEART

Tower erection is the process of installing communication towers, wind turbines, and other structures that require tall, sturdy support. It is a

Get Price

Phases of Construction & Erection for Wind Power

This document outlines the key phases and activities involved in constructing and commissioning a 300 MW wind power project. It discusses

Get Price

Wind Loading On Base Station Antennas White Paper

Its effects figure prominently in the design of every Andrew base station antenna. This paper focuses on how Andrew Solutions determines wind load values and Effective Drag Areas

Get Price

Rooftop Wind Turbines: Revolutionizing Urban

In the quest for sustainable and clean energy solutions, small rooftop wind turbines are emerging as a promising alternative for urban and

Get Price

Steel Building Erection Manual

This erection manual is intended as a support to the erection drawings that are furnished with each building. The erection drawings show the customer''s building as engineered and

Get Price

Wind loads on roof mounted telecommunications equipment:

Research and experience has shown that roof mounted equipment can be subject to significantly higher wind loads due to wind being diverted over and around buildings.

Get Price

Telecommunication Tower Reinforced Concrete Foundation

Telecom (Telecommunications) towers are a generic description of radio masts and towers built primarily to hold telecommunications antennas. As such antennas often have a large area and

Get Price

GOVERNMENT OF GHANA

The IMC instituted an Industry Technical Committee (ITC) headed by the National Communications Authority (NCA) to collaborate with industry and other stakeholders:

Get Price

Technical Keys to Successful Network Modernization:

Base station antennas add load to the towers not only due to their mass, but also in the form of additional dynamic loading caused by the wind. Depending on the aerodynamic efficiency of

Get Price

SAES-T-744 Design Criteria and Installation of Communication

SAES-T-744 Design Criteria and Installation of communication Towers - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Get Price

Optimum Selection of Communication Tower Structures

Although communication tower designs consider wind loads, numerous collapse incidents of the towers are due to wind disasters. They investigated the collapse analysis of a lattice

Get Price

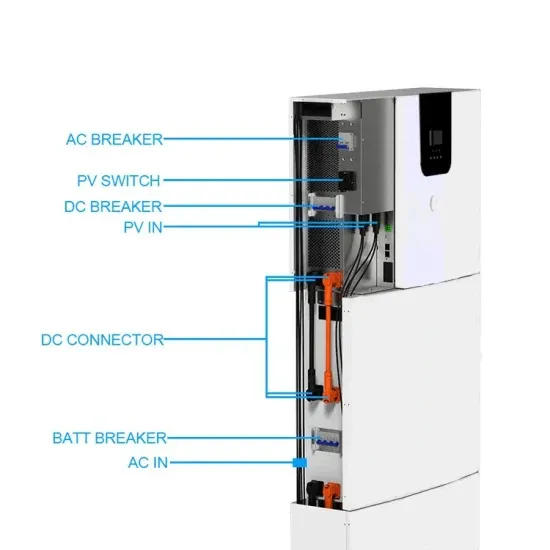

What is a base station energy storage power station

A base station energy storage power station refers to a facility designed to store energy generated from various renewable sources and

Get Price

Tower Erection

They are suitable for emergency communications, two-way radio, remote base stations, and cell-on-wheels (COW) applications. Communication tower erection services also build roof top

Get Price

Steps followed in setting a Wind Farm

Steps followed in setting a Wind Farm Listed below are the major steps followed and the costs involved in setting up a wind farm (in India), however the steps and the method of setting a

Get Price

Tower Erection for Transmission Lines | MECHHEART

Tower erection is the process of installing communication towers, wind turbines, and other structures that require tall, sturdy support. It is a complex and technical process that

Get Price

Rooftop tower

ASMTower is able to design rooftop masts and poles with struts and bracing members to optimize the capacity and reduce their buckling length of strut

Get Price

Wind loads on building mounted communications equipment

The purpose of this paper is to look at wind loads on building mounted antennas and associated equipment.

Get Price

DESIGN AND ANALYSIS OF 6M HIGH NON ANCHORED

The study covers the brief introduction of communication towers where the benefits of non-penetrating roof top pole are explained. A detail literature review is carried out as part of the

Get Price

Wind Turbine Mounted in Roof

2. Wind Resource Assessment: Wind Speed: Measure the average wind speed at the proposed installation site. Roof-mounted turbines

Get Price

EM385-1-1 Section 16 TOCFINAL.pdf

(4) Wind speed indicating device mounted on the crane, in a location where the maximum wind speed can be measured for the lifting activity. In lieu of the above and where wind speed and

Get Price

Wind Turbine Installation Guide

Wind Turbine Installation Guide How is a wind turbine installed? The length and complexity of the installation process depends upon the size and type of wind turbine. Prior to

Get Price

News

Communication is two-way, when the user''s mobile phone sends a signal to the base station, if the user is far away from the base station, the transmission power of the mobile phone will

Get Price

Tower Erection

They are suitable for emergency communications, two-way radio, remote base stations, and cell-on-wheels (COW) applications. Communication tower

Get Price

Communication Base Station Energy Solutions

The Importance of Energy Storage Systems for Communication Base Station With the expansion of global communication networks, especially the

Get Price

Building-Mounted Structures in the Telecommunications

While the International Building Code, ASCE/SEI 7, and ANSI/TIA-222 do not require positive attachment of roof-mounted equipment to the underlying structure, it may be

Get Price

6 FAQs about [Erection of communication base station wind power on the roof]

How do base station antennas affect tower load?

It is therefore important for wireless service providers and tower owners to understand the impact that each base station antenna has on the overall tower load. Base station antennas not only add load to the towers due to their mass, but also in the form of additional dynamic loading caused by the wind.

How does wind load affect a tower?

In addition, antennas, connections, mounts and equipment add load to the towers not only due to their mass, but also in the form of additional dynamic loading caused by the wind. Depending on the aerodynamic efficiency of the overall tower, the increased wind load can be significant.

Do base station antennas increase wind load?

Base station antennas add load to the towers not only due to their mass, but also in the form of additional dynamic loading caused by the wind. Depending on the aerodynamic efficiency of the antenna, the increased wind load can be significant. Additionally, there are other location-specific factors to consider when calculating antenna wind load.

What type of structure is used for a telecom tower foundation?

So very stable structure types like lower lattice towers and towers built of reinforced concrete are used in most cases, although also guyed masts are used for taller application. This case study focuses on the design of a telecom tower foundation using the engineering software program spMats.

How to erect a steel transmission tower?

There are four main methods of erecting steel transmission towers in the world. Helicopter method. In Sri Lankan and Indian tower erection projects normally used the “Section method”. and the Build- method. The major difference between these two methods is, two Gin poles normally use for the “Build-up Method”.

How does a hybrid cable affect tower weight & wind load?

The trend toward advanced optical fiber and hybrid cables supplanting coaxial cable in support of the latest antenna applications also has a significant impact on tower weight and wind load. A single hybrid cable can do the work of eight or more power and fiber cables, supporting multiple Remote Radio Units (RRUs).

More related information

-

The wind power station of the communication base station is built on the roof of the self-built building

The wind power station of the communication base station is built on the roof of the self-built building

-

Communication wind power base station enterprise

Communication wind power base station enterprise

-

Grenada communication base station wind and solar hybrid power generation installation

Grenada communication base station wind and solar hybrid power generation installation

-

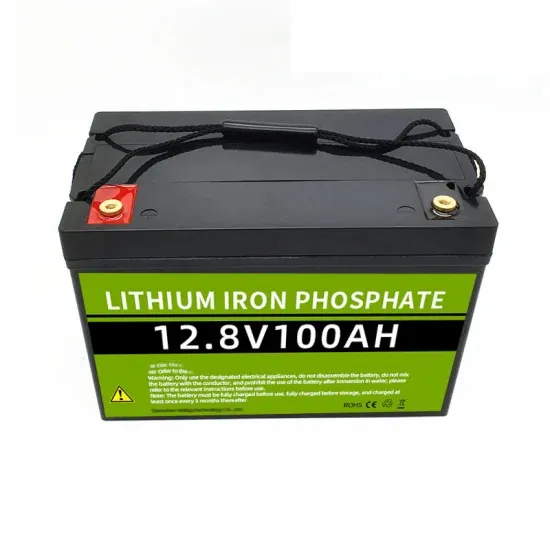

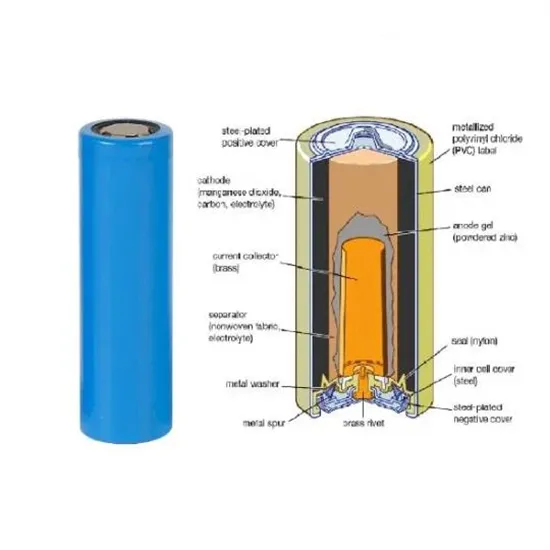

Communication base station wind power has batteries

Communication base station wind power has batteries

-

Southern Europe Communication Base Station Wind Power

Southern Europe Communication Base Station Wind Power

-

Communication base station wind power withdrawal small

Communication base station wind power withdrawal small

-

Capital Base Station Wind Power Supply Communication

Capital Base Station Wind Power Supply Communication

-

Cook Islands mobile communication wind power base station price

Cook Islands mobile communication wind power base station price

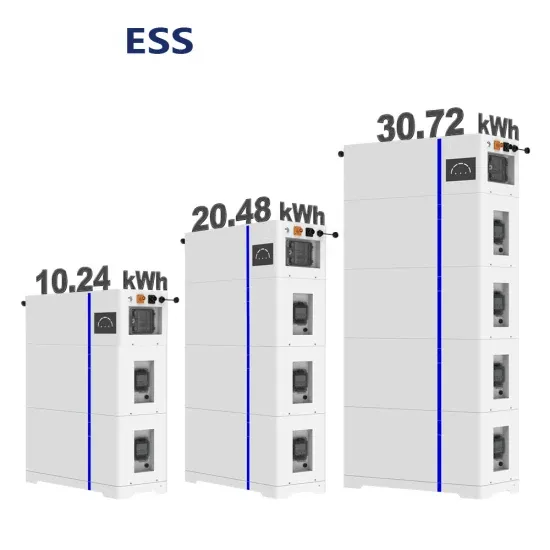

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.