Blogs, News, Events

Battery Energy Storage System (BESS) container enclosures play a critical role in ensuring the safe, efficient, and long-lasting operation of

Get Price

BESS Quality Manufacturing and QC for Energy Storage Systems

From battery cell production to final system assembly and quality control, each step must meet strict industry standards to guarantee a durable and high-performing energy storage solution.

Get Price

High-Quality BESS Container Manufacturing: TLS

Discover TLS Energy''s strict quality control process for BESS container manufacturing--ensuring safety, durability, and long-term energy

Get Price

Lead Intelligent Won the Bid for the First Fully Automatic Energy

Previously, energy storage containers mainly rely on manual assembly, which workers need to shuttle in more than 20 feet of containers to complete positioning, handling, assembly and

Get Price

BATTERY ENERGY STORAGE SYSTEMS

Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized.

Get Price

Container Energy Storage

We''re professional container energy storage manufacturers and suppliers in China, specialized in providing high quality customized service. Please rest

Get Price

Containerized Maritime Energy Storage | ABB Marine

ABB''s containerized energy storage solution is a complete, self-contained battery solution for a large-scale marine energy storage. The batteries and all control,

Get Price

In-Depth Overview of Battery Cell Assembly Processes

The process of battery cell assembly plays a crucial role in the development and production of energy storage devices. In a world increasingly reliant on

Get Price

Quality Control and Testing for Battery Energy Storage Systems

Our engineers confirm the final products are safely loaded without damage, secured, sealed, and accurately recorded on the Bill of Lading. CEA''s container loading monitoring reports include

Get Price

HOW TO DESIGN A BESS (BATTERY ENERGY

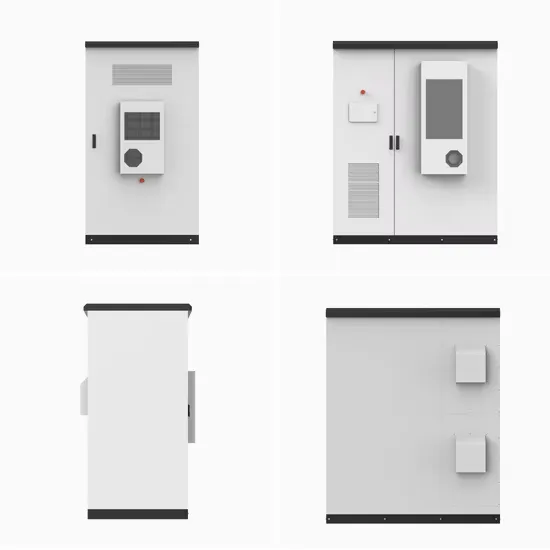

The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety,

Get Price

Energy Storage Container Assembly Line

Technical Parameter ﹀ Highlights of Energy Storage Container Assembly Line ﹀ Automatic container launch, door opening, cleaning, pre-install, and automated processing. Installing

Get Price

Battery Pack Assembly Process Series 7

After the battery cabin is online, it is generally necessary to check its appearance, size and protection level according to the requirements of the design drawings to ensure that

Get Price

Designing a BESS Container: A Comprehensive Guide to Battery Energy

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Get Price

The Assembly Process of 20ft Energy Storage

At TLS Offshore Containers, we follow a rigorous and systematic approach to the assembly of our energy storage containers, ensuring they

Get Price

BESS Assemblies: A Comprehensive Guide to the Complex

The following guide to BESS assembly is very informative, covering all the key components involved, stages of assembly, safety protocols, and a few key considerations that must be

Get Price

High-Quality BESS Container Manufacturing: TLS Energy''s

Discover TLS Energy''s strict quality control process for BESS container manufacturing--ensuring safety, durability, and long-term energy storage reliability.

Get Price

Energy Storage Quality Control | Applus+ USA

In addition to quality control services, we provide comprehensive BESS engineering services, offering a wide range of solutions at any stage of the project, from site evaluation and

Get Price

The Assembly Process of 20ft Energy Storage Containers by TLS

At TLS Offshore Containers, we follow a rigorous and systematic approach to the assembly of our energy storage containers, ensuring they meet the highest industry standards

Get Price

Advanced BESS Container Design and Fabrication by

TLS Energy designs and fabricates high-quality Battery Energy Storage System (BESS) containers, offering reliable, customizable, and safe

Get Price

Energy Storage Quality Control

By identifying and addressing potential defects in BESS components early, our QA/QC services minimize project risks, ensure compliance with quality standards, and ensure the durability of

Get Price

How TLS Offshore Containers Manufactures High

Conclusion TLS Offshore Containers'' commitment to quality and durability in container manufacturing strengthens global logistics. Through

Get Price

BESS Assemblies: A Comprehensive Guide to the Complex Process

The following guide to BESS assembly is very informative, covering all the key components involved, stages of assembly, safety protocols, and a few key considerations that must be

Get Price

Huijue Group was founded in 2002, is leading Hybrid Power

The goal is to ensure that every component works seamlessly together, resulting in a durable and reliable energy storage solution. Key Steps in the Assembly Process 1. Frame Assembly: The

Get Price

Energy storage container assembly line process standards

This production line is used for the semi-automatic production of energy storage containers, compatible with the production of main control box (673*711.5*234), electric box

Get Price

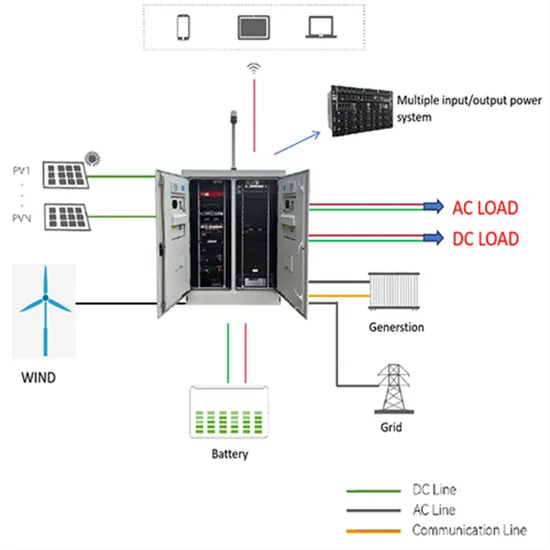

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is

Get Price

6 FAQs about [Energy storage container assembly process quality control]

Do battery energy storage systems look like containers?

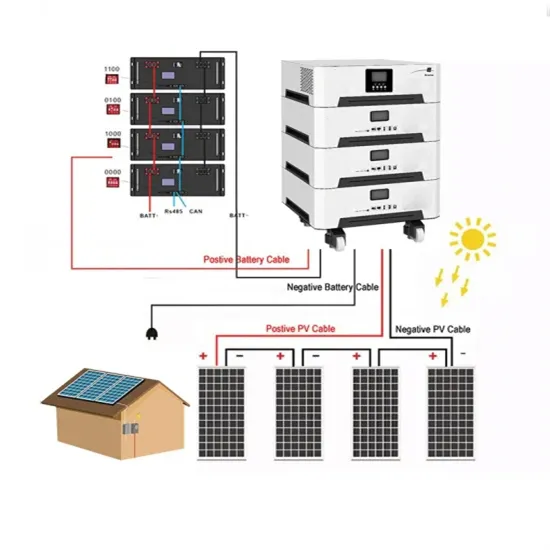

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What chemistry is used in battery energy storage system?

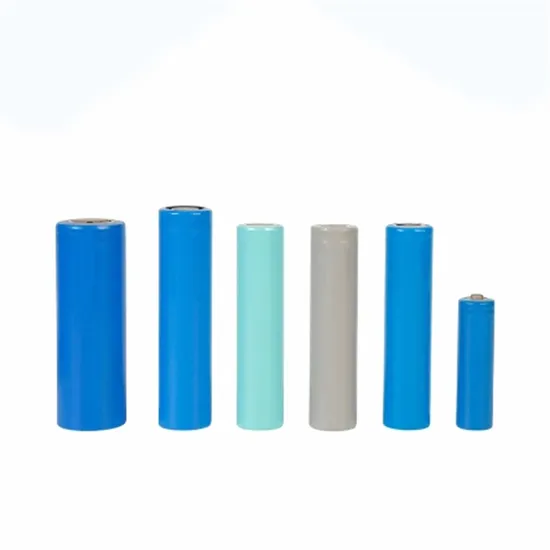

Do a quick research. •Battery cell chemistry:LFP (Lithium iron phos- phate – chemical formula LiFePO4) is the main chemistry used in the Battery Energy Storage System industry due to lower cost and increased safety.

What should be included in a contract for an energy storage system?

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

How to compare battery energy storage systems?

In terms of $, that can be translated into $/kWh, the main data to compare Battery Energy Storage Systems. Sinovoltaics’ advice: after explaining the concept of usable capacity (see later), it’s always wise to ask for a target price for the whole project in terms of $/kWh and $.

More related information

-

Energy Storage Container Assembly Process

Energy Storage Container Assembly Process

-

The whole process of energy storage container processing

The whole process of energy storage container processing

-

Container Energy Storage Battery Temperature Control

Container Energy Storage Battery Temperature Control

-

Energy storage container assembly

Energy storage container assembly

-

What is the installation process of the energy storage container

What is the installation process of the energy storage container

-

Energy storage container assembly automation equipment

Energy storage container assembly automation equipment

-

UAE container energy storage cabinet manufacturer

UAE container energy storage cabinet manufacturer

-

Finland Energy Storage Container Power Station Solution

Finland Energy Storage Container Power Station Solution

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.