What are pet solar panels? | NenPower

These specialized solar systems are designed explicitly with the needs of pets and their owners in mind. Pet solar panels harness the sun''s

Get Price

Connecting Reality and Looking Forward: PET Materials in the Solar

PET (polyethylene terephthalate) material has grown in popularity in the solar panel industry because of its superior performance and inexpensive cost. The growing

Get Price

What are pet solar panels | NenPower

Pet solar panels are innovative structures specifically designed to harness solar energy for powering pet-related devices and enhancing pet

Get Price

Discover the Benefits of Pet Solar Panels for Eco-Friendly Energy

Pet solar panels are solar panels specifically designed to power pet-related devices, such as heated beds or automatic feeders. These systems capture sunlight and convert it into energy.

Get Price

PET film for PV Market

PET films, used as backsheets and encapsulants in solar modules, are critical for protecting PV cells from moisture, UV radiation, and mechanical stress, ensuring long-term durability.

Get Price

Development of lightweight and flexible crystalline silicon solar

Lightweight and flexible solar cell modules have great potential to be installed in locations with loading limitations and to expand the photovoltaics market. We used

Get Price

PET Laminated Solar panel

The PET laminated solar panel is made by placing layers of PET, EVA, solar cell and PCB together. They are then laminated by machine at a temperature of

Get Price

What does a pet laminated solar panel look like? | NenPower

A pet laminated solar panel features several distinctive characteristics which set it apart in both functionality and aesthetics. 1. Design, a pet laminated solar panel displays a

Get Price

Backsheet Types for Solar PV Modules | RenewSys

It is a multilayer laminate formed by laminating two or more specialized polymer films together. Backsheets from the outermost and

Get Price

Why Flexible Solar Panels Are a Game-Changer

What to Look for When Buying Flexible Solar Panels: Key Factors to Consider Choosing the best flexible solar panel isn''t just about picking the

Get Price

The Role of PET Film in Solar Panels and Green Technologies

PET Film plays an important role in solar panels and green technologies. Its excellent properties and broad application prospects make it an important material in the field of renewable energy.

Get Price

The Difference Between TPT and PET for Solar Panels

TPT backsheets are known for their superior durability and weather resistance, making them a preferred choice for premium solar panels, while PET backsheets are a more

Get Price

Study on insulating properties of polyethylene

Photovoltaic (PV) power is one of the most effective green energies, which has attracted extensive attention from the industry and the

Get Price

UV Degradation of PET Coated Solar Panels

In summary, if you want a solar panel to last for more than occasional outdoor use, don''t use PET. We recommend ETFE, urethane or glass for long-term

Get Price

PET film for PV Market

The PET film supply chain for solar panels is concentrated among a mix of global leaders and regional specialists, with Asia-Pacific manufacturers dominating production capacity. Toray

Get Price

PET Laminated Solar panel

The PET laminated solar panel is made by placing layers of PET, EVA, solar cell and PCB together. They are then laminated by machine at a temperature of 135 degrees Celcius which

Get Price

Polyester Film for Solar Panel Encapsulation, PET Film

By leveraging these material performance characteristics, PET film effectively protects and enhances the performance of solar panels, making it a preferred choice for encapsulation.

Get Price

The Difference Between TPT and PET for Solar Panels

TPT backsheets are known for their superior durability and weather resistance, making them a preferred choice for premium solar panels,

Get Price

PET Monocrystalline Solar Panel 5 Volt

Customized 5V PET Mini Solar Panel, 5v solar panels factory provide solar panels of variety sizes, shapes and outputs, Top 5V solar panel manufacturers in China.

Get Price

Polyester Film for Solar Panel Encapsulation, PET

By leveraging these material performance characteristics, PET film effectively protects and enhances the performance of solar panels, making it a preferred

Get Price

Connecting Reality and Looking Forward: PET

PET (polyethylene terephthalate) material has grown in popularity in the solar panel industry because of its superior performance and

Get Price

PET Solar Panel

These UV resistance Matte PET laminated solar panels consisting of raw material of Matt PET, EVA, Solar cell and FR-4 PCB, it is laminated by machine at a

Get Price

PET Laminated Solar panels | Mini Solar Panels

PET solar panel suit for small solar products, such as solar toys, lighting, mobile power, various electronic products and so on.

Get Price

What is PET Solar Panel?

PET Solar Panel means that the top layer of encapsulated material is PET film, which is a plastic film with a light transmittance of about 85%. Its surface can look shiny without any treatment,

Get Price

Mini PET Solar Panel 5V 60mA Sun Cell 2pcs Polycrystalline Solar

Mini PET Solar Panel 5V 60mA Sun Cell 2pcs Polycrystalline Solar Cell Photovoltaic Panel For 3.6V Battery Charger DIY Toy LED 4V 0.2W 2-Wire Mini Epoxy Solar Panel with 8 Solar Cells

Get Price

PET Solar Panel

These UV resistance Matte PET laminated solar panels consisting of raw material of Matt PET, EVA, Solar cell and FR-4 PCB, it is laminated by machine at a temperature of 135℃, with

Get Price

3 Best Flexible Solar Panels (2025 Guide)

Flexible solar panels provide portable solar energy for outdoor and marine activities. Read our guide on the best flexible solar panels to learn more.

Get Price

RFID Solar Panel Management System | Solar PV RFID Solution

ID Tech Solutions being the leading RFID solar panel management system provider in India designed Solar PV RFID Solution that writes data into RFID Solar tags that are stuck on Solar

Get Price

6 FAQs about [Pet solar photovoltaic panels]

What is PET solar panel?

PET Solar Panel means that the top layer of encapsulated material is PET film, which is a plastic film with a light transmittance of about 85%. Its surface can look shiny without any treatment, and if it is sprayed with a layer of frosted, it will look matte and a little rough to the touch.

What does a PET solar panel look like?

Its surface can look shiny without any treatment, and if it is sprayed with a layer of frosted, it will look matte and a little rough to the touch. PET solar panels are customized products with small sizes or low power output.

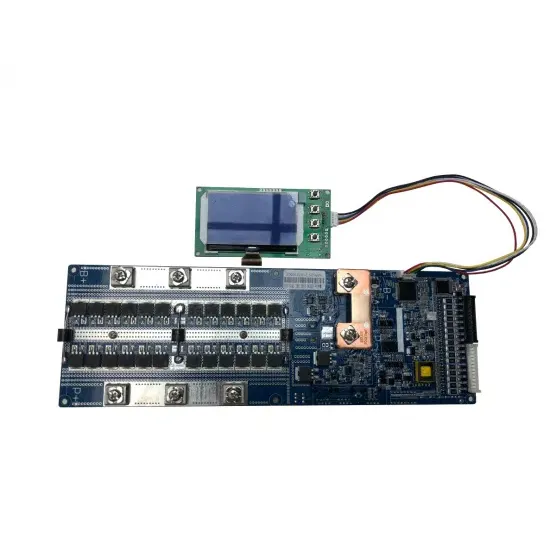

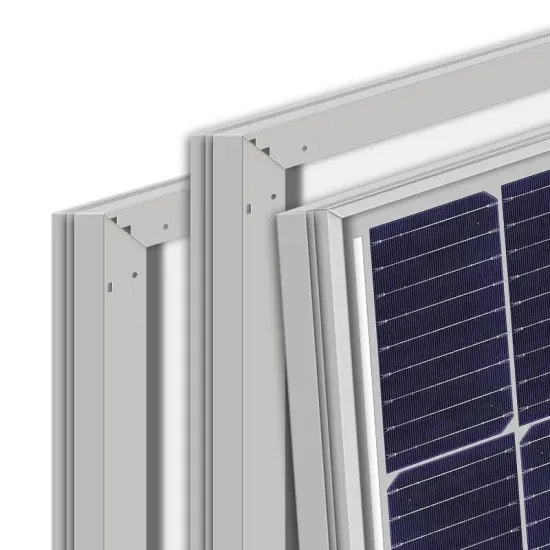

What is a pet laminated solar panel PCB?

The PET laminated solar panel is made by placing layers of PET, EVA, solar cell and PCB together. They are then laminated by machine at a temperature of 135 degrees Celcius which will melt the encapsulating materials together to form a watertight bond. How the back of a PET laminated solar panel PCB look like.

Why is PET film Bad for solar panels?

1. Long-term exposure to the outdoors will make the PET film hard, brittle, and discolored, reducing the light transmittance of the solar panel, and at the same time, it can’t well protect the PV cells inside to avoid oxidation and corrosion.

What is the difference between TPT & pet for solar panel backsheets?

TPT (Tedlar/PET/Tedlar) and PET (Polyethylene Terephthalate) are two different materials used in the construction of the backsheet of solar panels. The backsheet is a crucial component that protects the solar cells from environmental factors and provides electrical insulation. Here’s a comparison of TPT and PET for solar panel backsheets:

What are the advantages and disadvantages of PET solar panels?

1. It is suitable for the production of solar modules of various sizes and different voltages and currents to meet different application scenarios. 2. Quality standards are lower than glass laminated solar panel. 3. Short lamination time and high production efficiency. 4. Low cost. What are the disadvantages of PET solar panels? 1.

More related information

-

Two photovoltaic solar panels on a Ukrainian roof

Two photovoltaic solar panels on a Ukrainian roof

-

Factory solar photovoltaic panels

Factory solar photovoltaic panels

-

What kind of silicon is used to make solar photovoltaic panels

What kind of silicon is used to make solar photovoltaic panels

-

South Sudan rural solar panels photovoltaic panels

South Sudan rural solar panels photovoltaic panels

-

Are solar panels and photovoltaic panels the same

Are solar panels and photovoltaic panels the same

-

What types of solar panels are there in photovoltaic modules

What types of solar panels are there in photovoltaic modules

-

Micro solar photovoltaic panels

Micro solar photovoltaic panels

-

45100mm solar panels photovoltaic panels

45100mm solar panels photovoltaic panels

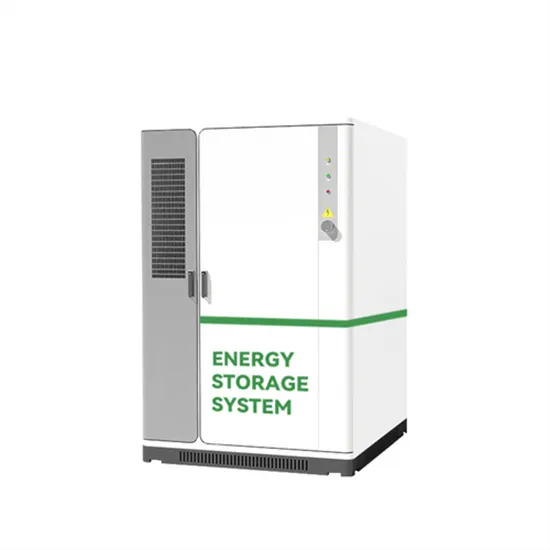

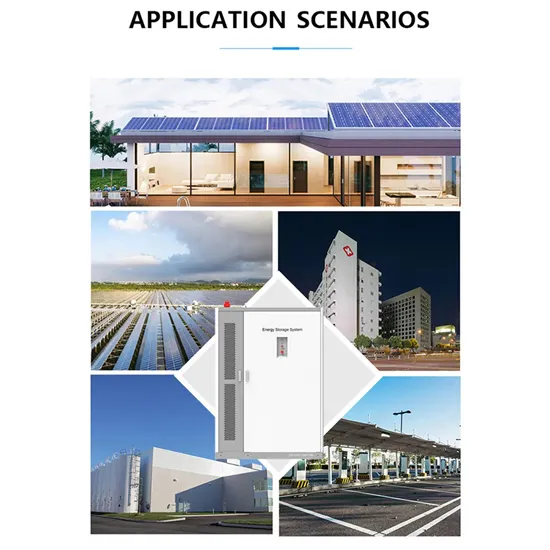

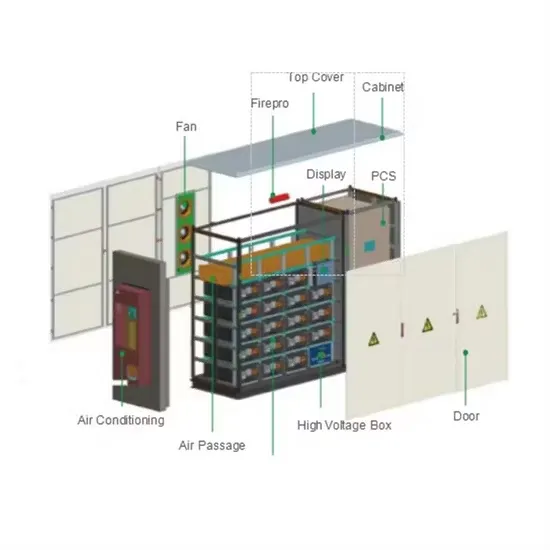

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.