A Detailed Guide To The Solar Project Development Process

Discover the solar project development process, uncover financing options, and gain valuable insights for a successful project in this comprehensive guide.

Get Price

Training Photovoltaic Modules | Industry

Discover our complete training on the photovoltaic module industry : manufacturing, technology, market, regulation and quality.

Get Price

Adani Solar

About Adani Solar Adani Solar is the solar PV manufacturing arm of Adani Group, India''s largest and most diversified business conglomerate. The group

Get Price

How To String Solar Panels?

One can take the solar panel or module as the housing for the cells. So, a 12V solar panel/module has 36 or 72 cells that are connected in

Get Price

Utility scale solar PV projects

Utility scale solar PV projects These precedent Project Documents aim to provide a strong base for delivering a solar PV facility from initiation to operation, for developers of all experience

Get Price

Photovoltaic Cell Manufacturing Plant Report 2025:

The photovoltaic cell manufacturing plant project provides detailed insights into business plan, unit setup, cost, machinery and raw material requirements.

Get Price

Building-Integrated Photovoltaic Desings for Commerical and

Modules are strung together in an electrical series with cables and wires to form a PV array. Direct or diffuse light (usually sunlight) shining on the solar cells induces the photovoltaic

Get Price

Cells, Modules, Panels and Arrays

Photovoltaic cells are connected electrically in series and/or parallel circuits to produce higher voltages, currents and power levels. Photovoltaic modules consist of PV cell circuits sealed in

Get Price

The Anatomy of a Solar Cell: Constructing PV Panels Layer by

Discover the remarkable science behind photovoltaic (PV) cells, the building blocks of solar energy. In this comprehensive article, we delve into the intricate process of PV

Get Price

Photovoltaic Cell and Module Design | Department of Energy

Conducting research on PV cell and module design aims to deliver technologies that drive down the costs of solar electricity by improving PV efficiency and lowering manufacturing costs while

Get Price

Solar Photovoltaic Technology Basics | NREL

Solar Photovoltaic Technology Basics Solar cells, also called photovoltaic cells, convert sunlight directly into electricity. Photovoltaics (often

Get Price

Photovoltaic Cell Manufacturing Plant Report 2025: Setup & Cost

The photovoltaic cell manufacturing plant project provides detailed insights into business plan, unit setup, cost, machinery and raw material requirements.

Get Price

Solar Photovoltaic (PV) Systems

Grid-connected solar PV systems The main application of solar PV in Singapore is grid-connected, as Singapore''s main island is well covered by the national power grid. Most solar

Get Price

Spring 2024 Solar Industry Update

Spring 2024 Solar Industry Update David Feldman Jarett Zuboy Krysta Dummit, Solar Energy Technologies Office Dana Stright Matthew Heine Shayna Grossman, ORISEa Fellow Robert

Get Price

Avada Group wants to build ingot-to-PV module, battery factory in

Avaada will set up a wafer-to-module project to support the company''s existing PV module plant in Dadri. The factory will also manufacture next-generation batteries and

Get Price

Processes for the assembly and production of solar

In short, a number of specialists and 20-25 machines closely work together from cell to module. The process revolves around ten major steps, which divide into

Get Price

The Anatomy of a Solar Cell: Constructing PV Panels

Discover the remarkable science behind photovoltaic (PV) cells, the building blocks of solar energy. In this comprehensive article, we delve

Get Price

pvi-14.pdf

Since October 2010, Dr. Wirth has headed the new division of Photovoltaic Modules, Systems and Reliability, which is mainly engaged in the development, testing and monitoring of photovoltaic

Get Price

Photovoltaic Cell Generations and Current Research

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and

Get Price

Photovoltaic Cell and Module Design | Department of Energy

Discover the solar project development process, uncover financing options, and gain valuable insights for a successful project in this comprehensive guide.

Get Price

PNE AG | Photovoltaics

Our core competences include top-quality site evaluation, land securing, project development and the turnkey construction of ground-mounted photovoltaic systems.

Get Price

Module 10 Design and Implementation Guidelines for Stand

This module was developed for institutions and individuals involved in the promotion, design, and implementation of stand-alone solar photovoltaic (solar PV) rural electrifi cation projects.

Get Price

Standards for PV Modules and Components Recent

New standards under development include qualification of junction boxes, connectors, PV cables, and module integrated electronics as well as for testing the packaging used during transport of

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal

Get Price

Processes for the assembly and production of solar panels

In short, a number of specialists and 20-25 machines closely work together from cell to module. The process revolves around ten major steps, which divide into several sub-steps, to produce

Get Price

SunPower – Powering a Brighter Future | SunPower®

We provide residential solar, battery storage, and custom solutions for homes, built to last with quality and backed by decades of solar expertise.

Get Price

Photovoltaic Cell Generations and Current Research Directions

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and manufacturing technologies.

Get Price

6 FAQs about [Photovoltaic module group formation project]

What is PV module construction?

From the individual photovoltaic cells, the next step in PV module construction is connecting and packaging these cells into functional solar panels. This process involves several key steps to ensure optimal power output, durability, and longevity of the finished product.

What is PV cell and module technology research?

PV cell and module technology research aims to improve efficiency and reliability, lower manufacturing costs, and lower the cost of solar electricity.

How a photovoltaic module is assembled?

The assembly of photovoltaic modules consists of a series of consecutive operations that can be performed by automatic machines dedicated to optimizing the single production phases that transform the various raw material in a finished product.

How a photovoltaic cell can be integrated into a production line?

Some of this equipment can be integrated into the production line according to the wished level of automation. The photovoltaic cells are placed in a piece of equipment, called solar stringer, that interconnects the cells in a series by soldering a coated copper wire, called ribbon, on the bus bar of the cell.

Can PV modules be integrated into building materials?

The integration of PV into well-known building materials, such as roof tiles, is under way. Attention to these devel-opments around the world shows the cost reduction potential of this R&D path. Optimal tuning of PV modules to exist-ing building materials can result in sub-stantial reduction of mounting and substructure costs.

What is a commercial PV module?

Module Commercial PV product containing interconnected solar cells; modules come in various standard sizes and can also be custom-made by the manufacturer. Group or string of connected PV modules operating as a single unit. PV laminate Building component constructed of multilayers of glass, metal or plastic and a photovoltaic material.

More related information

-

Huawei photovoltaic module export project

Huawei photovoltaic module export project

-

New photovoltaic module project in Mali

New photovoltaic module project in Mali

-

Spain Photovoltaic Module Project

Spain Photovoltaic Module Project

-

Photovoltaic module project third party

Photovoltaic module project third party

-

Moldova Lightweight Photovoltaic Module Project

Moldova Lightweight Photovoltaic Module Project

-

Photovoltaic cell module production project

Photovoltaic cell module production project

-

Mozambique photovoltaic module project Changtong

Mozambique photovoltaic module project Changtong

-

Somaliland Photovoltaic Module Factory Project

Somaliland Photovoltaic Module Factory Project

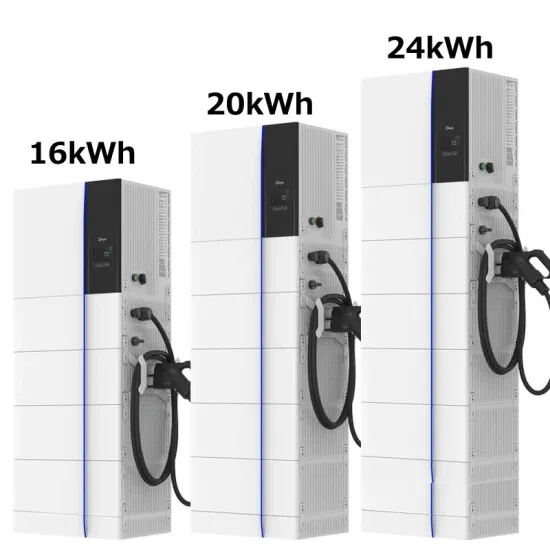

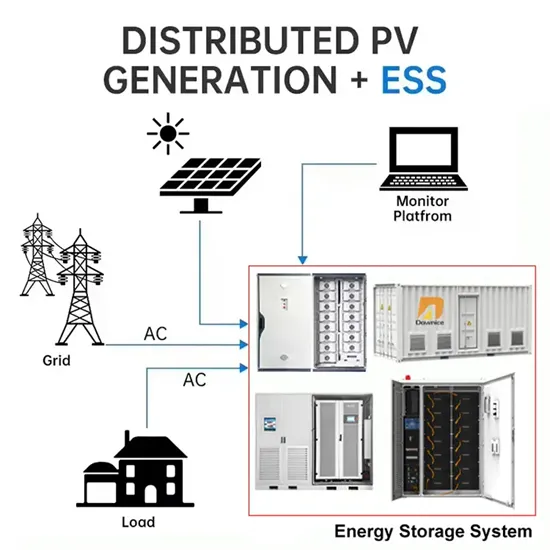

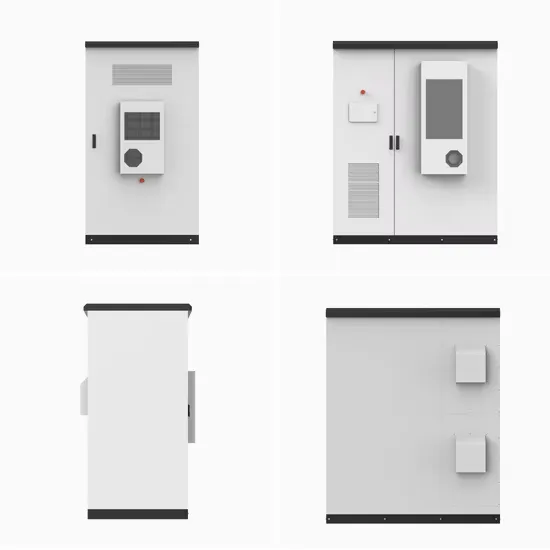

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.