China Discount Small 40W Solar Panels Household Suppliers Factory

Products Description The Small 40W Solar Panels are ideal for households that are looking to transition towards sustainable energy sources and reduce their carbon footprint. These panels

Get Price

Can a solar system power a factory?

Improved Return on Investment Utilizing previously unused rooftop space to install solar panels can generate electricity for the factory''s consumption. Under the Capital Expenditure model,

Get Price

Investment Plan to Build a Solar Panel Factory

In addition, you can offer your products to both local and international markets by evaluating growth opportunities in the renewable energy sector. When creating a "solar energy

Get Price

Investment Plan to Build a Solar Panel Factory

The process of setting up a Solar Panel Factory can be successful with proper planning and implementation. First of all, it is critical to determine the production capacity of

Get Price

Solar Power for Factory, Warehouse & Industrial

Why harness solar energy for your factory or industrial building roof? The roofs of factories are often the ideal place to install solar panels. As factories are

Get Price

40 Watt Solar Panel: Everything You Need To Know

you''ll learn, how much power you can expect from a 40-watt solar panel, what you can power with it, right size battery, charge controller,

Get Price

40W Solar Panel

When you choose our 40W solar panel on AliExpress, you''re not only investing in quality but also in customer satisfaction. We stand behind our products with exceptional after-sales support,

Get Price

Can a solar system power a factory?

We will explore various aspects from energy demands to legislative requirements, and from technological advancements to real-world examples, to provide an in-depth understanding of

Get Price

Ankara Solar

Ankara Solar, Turkey''s solar panel manufacturer, is a leading global provider of comprehensive photovoltaic (PV) solar energy solutions that are truly Taking Energy Forward. By integrating

Get Price

Cost of Setting Up a Solar Panel Manufacturing Plant

Learn how to plan capital investment, manage raw material costs, post manufacturing cost and optimize operations for setting up solar panel plant.

Get Price

How Manufacturing Plant Can Save With Solar Panel,

By investing in solar technology, plants can not only improve their bottom line but also contribute to a cleaner, greener future. The integration of

Get Price

How to build a solar photovoltaic panel factory

The initial investment for establishing a solar photovoltaic panel factory can vary significantly based on several factors, including the factory''s

Get Price

How Much Investment Do You Need For A Solar Farm?

When it comes to alternative investment options to pick from outside of bonds and stock, the solar farm is one of the popular choices. We say this because it also has a great potential to

Get Price

40 Watt Solar Panel: Everything You Need To Know

40W solar panel is enough to recharge your small appliances like cell phones, portable Fans, and LED lights. So in short, you''ll only be able to get 200 watts of total power

Get Price

What Are the 9 Startup Costs for a Solar Panel Manufacturing

Discover the 9 startup costs for a solar panel manufacturing plant. Learn about equipment, facilities, and operational expenses for success.

Get Price

Federal Tax Credits for Solar Manufacturers

Manufacturers are eligible for two federal tax credits that support clean energy manufacturing in the United States: the Advanced Manufacturing Production Tax Credit (45X MPTC) and the

Get Price

Cost Efficiency: How To Plan Financially For A Solar

You can launch a solar panel manufacturing plant with minimal expenses by leveraging smart strategies that lower your initial investment.

Get Price

The Ultimate Guide to Solar Panel Output

Solar panel output is the prime indicator of the solar-powered system''s effectiveness. The higher the solar panel power output is, the more it

Get Price

How to Start a Solar Panel Manufacturing Plant: Complete Guide

Once the site is chosen, you''ll need to invest in the necessary equipment and technology to streamline your production process. Additionally, consider the regulatory environment in your

Get Price

Solar Panel Manufacturing Cost: A Complete Factory

Working capital is necessary for solar panel production because you need to purchase materials before producing the panels, and only then

Get Price

Luminous to Build RE-Powered Solar Panel Factory in

Luminous'' upcoming solar panel plant will be fully-robotic in the manufacturing process. It will be capable of producing solar panels of 500 MW

Get Price

Industrial Solar Power & Installation | Solar Alliance

Your factory or manufacturing plant can save money and boost energy efficiency with our industrial solar panels. Click here to learn more and get in touch!

Get Price

How about opening a solar photovoltaic panel factory

1. Establishing a solar photovoltaic panel factory represents a significant opportunity in today''s renewable energy landscape.2. It addresses pressing ecological

Get Price

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Working capital is necessary for solar panel production because you need to purchase materials before producing the panels, and only then can you sell them. In this

Get Price

What Are the 9 Startup Costs for a Solar Panel

Discover the 9 startup costs for a solar panel manufacturing plant. Learn about equipment, facilities, and operational expenses for success.

Get Price

3SUN Gigafactory

3SUN Gigafactory Catania''s "Sun Factory," where high-efficiency solar cells and modules are made, is Europe''s largest center for the production of next-generation photovoltaic modules.

Get Price

Unlock the Costs of Starting a Solar Panel Manufacturing

When launching a solar panel manufacturing business, one of the most significant expenses is the acquisition of manufacturing equipment. This key investment is essential for

Get Price

Solar PV Module Manufacturing Cost Analysis | Case Study

Global adoption of solar energy is being aided by government policies and incentives like net metering schemes, tax breaks, and subsidies. Additionally, solar energy is becoming more

Get Price

How to build a solar photovoltaic panel factory | NenPower

The initial investment for establishing a solar photovoltaic panel factory can vary significantly based on several factors, including the factory''s size, technology chosen, and

Get Price

How Much Does It Cost to Start a Solar Panel

When starting a solar panel manufacturing plant, the initial investment can be one of the most daunting aspects. This includes costs associated with land

Get Price

6 FAQs about [Can 40w invest in a solar photovoltaic panel factory]

Should you invest in solar panel manufacturing?

Investing in solar manufacturing is investing in a sustainable future. Once your solar panel manufacturing plant is up and running, it’s essential to keep a close eye on operating costs. These costs can significantly affect your profit margins. Key expenses include labor, utilities, maintenance, and raw materials.

Is a 40W solar panel enough?

40W solar panel is enough to recharge your small appliances like cell phones, portable Fans, and LED lights. So in short, you'll only be able to get 200 watts of total power output from your 40W solar panel so is that what you need? then it is enough for you.

What is a solar panel manufacturing plant Complete Guide?

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every aspect of setting up and operating a solar panel manufacturing plant, ensuring you have the knowledge and tools to succeed in this booming industry.

What are solar panel manufacturing costs?

These costs encompass everything from equipment and labor to raw materials and operational expenses. In short, starting a solar panel manufacturing plant involves a complex web of financial considerations that must be navigated to ensure success. Overview of solar panel manufacturing costs. Breakdown of capital expenses.

How important is the location of a solar panel manufacturing plant?

How important is the location of the manufacturing plant? The location of your solar panel manufacturing plant greatly affects operational costs, supply chain efficiency, and access to skilled labor. What equipment is essential for solar panel manufacturing?

How does financial planning affect solar manufacturing?

Financial planning for solar manufacturing. When starting a solar panel manufacturing plant, the initial investment can be one of the most daunting aspects. This includes costs associated with land acquisition, facility construction, and the purchase of specialized equipment. The scale of your operation will greatly influence these costs.

More related information

-

Photovoltaic solar panel factory investment

Photovoltaic solar panel factory investment

-

New solar photovoltaic panel factory in West Africa

New solar photovoltaic panel factory in West Africa

-

What is the constant temperature of the solar photovoltaic panel factory

What is the constant temperature of the solar photovoltaic panel factory

-

Moroccan solar panel photovoltaic factory

Moroccan solar panel photovoltaic factory

-

Ecuadorian solar photovoltaic panel assembly factory

Ecuadorian solar photovoltaic panel assembly factory

-

Solar Panel Photovoltaic Water Pump Inverter

Solar Panel Photovoltaic Water Pump Inverter

-

Power Generation Solar Panel Photovoltaic Project Introduction

Power Generation Solar Panel Photovoltaic Project Introduction

-

Huawei Bhutan Solar Photovoltaic Module Factory

Huawei Bhutan Solar Photovoltaic Module Factory

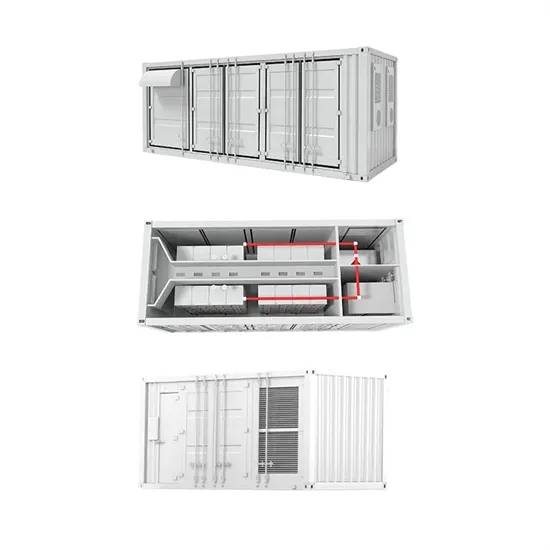

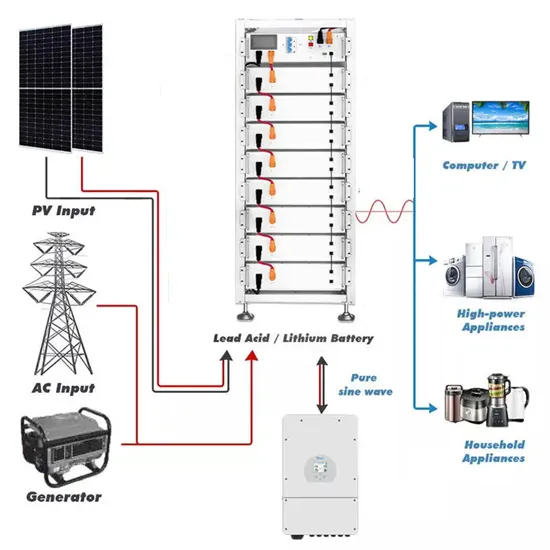

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

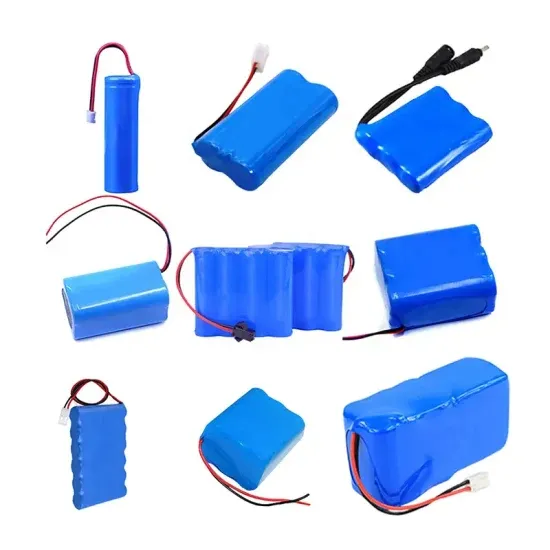

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.