PV Failure Fact S Sheets (PVFS) 2023

PV FAILURE FACT SHEETS (PVFS) The PV failure fact sheets (PVFS, Annex 1) summarise some of the most important aspects of single failures. The target audience of these PVFSs are

Get Price

Photovoltaic Panel Transportation Damage Rate: Costs, Causes,

The $2.1 Billion Problem: Solar Panel Transportation Damage Explained Did you know that roughly 1 in 5 photovoltaic panels sustains some form of damage during transportation?

Get Price

A Guide to Solar Panel Quality Check During

Why Solar Panel Quality Check During Production Inspection? Whether you''re an importer or manufacturer, ensuring that the solar products

Get Price

How to Protect Solar Panels from Damage Transporting and

The process of producing a high-quality PV module takes effort and energy to create. Which is why it can be frustrating, for the end-user and manufacturer, when a module

Get Price

Shipping Solar Panels Freight SideKick

Key Takeaways Shipping solar panels requires careful handling due to their fragile nature, which helps minimize damage risks and ensures

Get Price

Broken Solar Panels? You''re Not Alone.

Despite their durability, panels are vulnerable to damage in transit, with breakage rates of 1-2%. The industry is pushing for improved testing and

Get Price

Broken Solar Panels? You''re Not Alone.

Despite their durability, panels are vulnerable to damage in transit, with breakage rates of 1-2%. The industry is pushing for improved testing and handling standards to better

Get Price

How to Protect Solar Panels from Damage Transporting

Solar industry is still young, and panels from manufacturers around the world are all different. However, some lessons have been learned and general guidelines for moving

Get Price

How to protect solar panels from damage during transit

Statistics show that almost 5% of panel damages occur during shipping and transportation. 80% of globally installed solar PV modules are produced in Asia, primarily in

Get Price

What Happens If You Damage a Solar Panel?

What Happens If You Damage a Solar Panel? Solar panels are a long-term investment that provides clean and renewable energy for homes, businesses, and off-grid

Get Price

What should we pay attention to when transporting

Regulations governing the transportation of solar panels may differ considerably based on jurisdiction, encompassing everything from vehicle

Get Price

Last-Mile Solar Logistics Guide

Solar panel shipments are transported globally through a complex international supply chain – involving manufacturers, freight forwarders,

Get Price

How to protect solar panels from damage during transit

Solar industry is still young, and panels from manufacturers around the world are all different. However, some lessons have been learned

Get Price

Common Fault Diagnosis and Maintenance Guide for PV Systems

However, during long-term operation, PV systems may encounter common faults. This article will introduce common types of failures in PV systems along with their diagnosis

Get Price

How can solar panels be protected from damage during shipping?

Solar PV panels are delicate, and even the best-made panels can be damaged, scratched, or rendered useless due to poor logistics. According to statistics, over 5% of panel

Get Price

Manufacturing & Transportation – Solar Photovoltaic

Manufacturing and transportation practices can be addressed in order to limit the environmental impact. The figure below shows how the electricity mix involved

Get Price

The Truth About Solar Panels in Hurricanes: Do They Blow Off?

With a push toward green energy, countries like the US, Canada, and much of the European Union are encouraging people to install solar panels on homes for energy and

Get Price

The delicate matter of protecting solar panels during shipping

The risk for damage is seen where solar panels are palleted and how hands or equipment get those modules to the next point in the chain. Panels are usually flat-stacked or

Get Price

Manufacturing & Transportation – Solar Photovoltaic Technology

Manufacturing and transportation practices can be addressed in order to limit the environmental impact. The figure below shows how the electricity mix involved in the manufacturing process

Get Price

What should we pay attention to when transporting solar panels?

Regulations governing the transportation of solar panels may differ considerably based on jurisdiction, encompassing everything from vehicle restrictions to specific safety

Get Price

The delicate matter of protecting solar panels during

The risk for damage is seen where solar panels are palleted and how hands or equipment get those modules to the next point in the chain.

Get Price

Top 5: Factors Responsible for Glass Breakage in Solar Modules

Furthermore, Improving handling and packaging methods to prevent damage before installation is always better. #3 Edge Pinch During Lamination Double-glass PV

Get Price

4 Logistics Challenges for Solar Panels and How to Overcome

Solar panel transport carries significant risk because of the panels'' size and delicate nature. Minimizing movement and vibrations is essential during transit, as rough roads

Get Price

CPCB Issues Draft Guidelines for Solar Waste

It includes rejects and waste generated during manufacturing, refurbishment, and repair processes. It also covers solar modules that were

Get Price

Challenges and Prospects in Photovoltaic Waste Management

Photovoltaic (PV) technology advances swiftly towards achieving Net-Zero emissions, driving exponential growth in global installations. This surge in solar energy

Get Price

Micro Cracks in Solar Modules: Causes, Detection

Selecting a solar panel manufacturer that acknowledges the prevention of micro-cracks is a critical part of the solution. Minimal human

Get Price

How can solar panels be transported internationally?

Since the panels are fragile and susceptible to damage during transport, quality packaging materials and cushioning techniques should be used to minimize shock and vibration.

Get Price

4 Logistics Challenges for Solar Panels and How to

Solar panel transport carries significant risk because of the panels'' size and delicate nature. Minimizing movement and vibrations is essential

Get Price

How can solar panels be transported internationally?

Since the panels are fragile and susceptible to damage during transport, quality packaging materials and cushioning techniques should be

Get Price

Transporting Solar Panels Safely: Best Practices for Solar Module

It is possible to transporting solar panels without harming them by following suitable packaging, handling, and logistic rules.

Get Price

6 FAQs about [Are manufacturers responsible for damage to photovoltaic panels during transportation ]

How to transport photovoltaic solar panels?

The transport of solar panels and all the components associated with this type of renewable energy can be done by road by truck or rail, by air or by container ship. What issues need to be considered when transporting photovoltaic solar panels? Suitable packaging: The first step is to ensure proper packaging for the solar panels.

Why are solar panels damaged?

The reasons can range anywhere from rough handling of the packed modules to vibrations or shocks that occur in the back of a truck, on rail, or during transshipment on the sea. The most common damages to solar panels are breakages and cracks of the solar cells in the modules. Very often, they are visible directly to the human eye.

Can solar panels be transported around the world?

Unfortunately, the protocol for transporting PV modules that would become a standard for everybody hasn't been developed yet. Solar industry is still young, and panels from manufacturers around the world are all different. However, some lessons have been learned and general guidelines for moving solar panels around are already worked out.

Where do solar panels get damaged?

Statistics show that almost 5% of panel damages occur during shipping and transportation. 80% of globally installed solar PV modules are produced in Asia, primarily in Taiwan, Malaysia, the Philippines, and approximately 50% in China. The journey of these modules to reach their destination is long.

How to protect solar panels from damage?

To be on the safe side, collecting data on the journey of solar panels by monitoring the environmental conditions during transit might reveal damage hotspots and also comes in handy during the claims process. Inspect the solar panel before shipping for any apparent damage. Pack your panels vertically.

What are the challenges of solar panel logistics?

Here are four top challenges of solar panel logistics and how to address them. Solar panels are built to weather long-term outdoor installation but are highly prone to damage in storage. Since photovoltaic panels are as heavy as they are delicate, they also hold an elevated risk of shocks and drops when handled poorly.

More related information

-

Recommended manufacturers of photovoltaic panels in Türkiye

Recommended manufacturers of photovoltaic panels in Türkiye

-

Photovoltaic panels and solar pressure container manufacturers

Photovoltaic panels and solar pressure container manufacturers

-

Recommended manufacturers of photovoltaic panels in Myanmar

Recommended manufacturers of photovoltaic panels in Myanmar

-

Manufacturers of original photovoltaic panels

Manufacturers of original photovoltaic panels

-

Brand manufacturers of photovoltaic panels in Uganda

Brand manufacturers of photovoltaic panels in Uganda

-

Special pressure plate manufacturers for photovoltaic panels

Special pressure plate manufacturers for photovoltaic panels

-

Combination of photovoltaic panels and batteries

Combination of photovoltaic panels and batteries

-

Cape Verde solar panels and photovoltaic modules sales

Cape Verde solar panels and photovoltaic modules sales

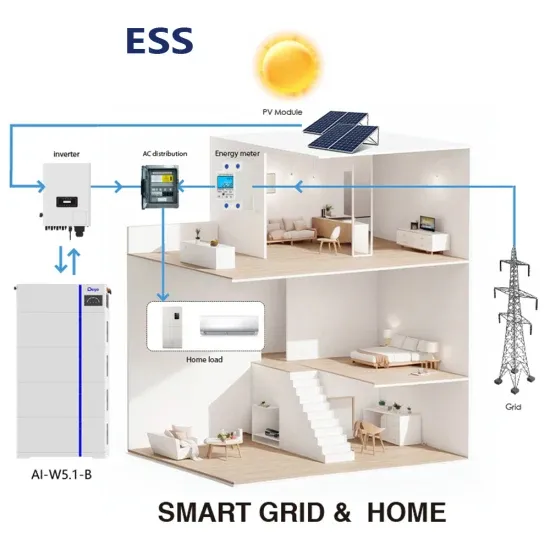

Commercial & Industrial Solar Storage Market Growth

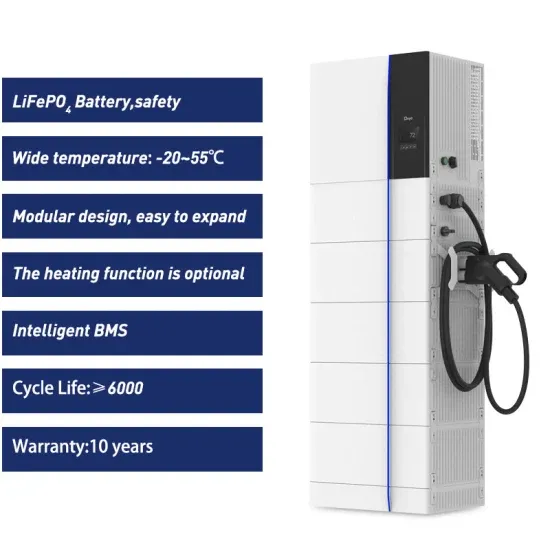

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.