Where Does a Solar PV Inverter be Installed? | inverter

The installation of the machine should be away from the ground with an appropriate height, for the convenience of observing and reading the LED display. When installing

Get Price

How to Calculate the Minimum Distance Between PV

How to Calculate the Minimum Installation Distance for Solar Panels? Designing appropriate spacing for inclined or ground-mounted photovoltaic systems can

Get Price

Ground-Mounted Solar Panels: What You Need to Know

Ground-mounting solar systems are simply solar panel arrays installed on the ground instead of roofs. Depending on how the rack system is configured, you

Get Price

Solis Seminar 【Episode 58】: Enhancing Inverter Protection

In addition, the ground cable terminal connected to the AC side of the inverter must be treated with a heat shrink sleeve to prevent rainwater from entering the inverter through the

Get Price

INSTALLATION MANUAL V2 22.05.2019.cdr

The system is a non-separately derived system. The following components have been evaluated for bonding as the fault current ground path: PV module, Mid Clamp, End

Get Price

Guidelines for Designing Grounding Systems for Solar

It should run with the circuit or current-carrying conductor in the same raceway or cable when it leaves the vicinity of the PV array. 14)

Get Price

what''s the lowest wall mounting height for sma 5kw inverter in

what''s the lowest wall mounting height for sma 5kw inverter in garage? the wire is a couple of feet short and I''d just like to lower them a couple of feet., about 2 feet off the floor, but maybe there

Get Price

Best location for inverter | Inside vs outside? Warranty issues?

If a metal back sheet is used under conditions of direct sunlight, it is recommended to leave 30 cm of clearance between the sheet and the inverter. A clearance of under 30 cm may cause the

Get Price

Clause 10.2

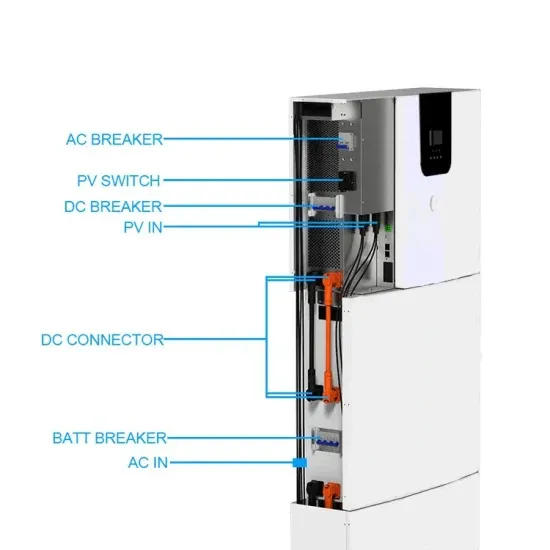

(1) Manual emergency shut-off system for the disconnection of the PV modules shall be provided on both the AC-power side (typically where inverters are

Get Price

Standards and Requirements for Solar Equipment,

Installation on of rooftop solar PV systems raises issues related to building, fire, and electrical codes. Because rooftop solar is a relatively new technology and often added to a building after

Get Price

Enhancing Inverter Protection Best Practices for Outdoor

In addition, the ground cable terminal connected to the AC side of the inverter must be treated with a heat shrink sleeve to prevent rainwater from entering the inverter

Get Price

Where Does a Solar PV Inverter be Installed?

The installation of the machine should be away from the ground with an appropriate height, for the convenience of observing and reading the LED

Get Price

Bif a cial Design guiDe

Electrical Specifications of the bifacial PV module It is very important to identify the estimated bifacial gain before designing the system. After determining the expected bifacial gain under

Get Price

What Is the Average Height of Ground Mounted Solar Panels?

The average height generally ranges from 3 to 5 feet above the ground. However, this can vary based on several factors, including the type of solar panel system, the local

Get Price

Best location for inverter | Inside vs outside? Warranty issues?

As per ESV.vic.gov , the minimum height to the bottom of the inverter can''t be less than 500mm from the ground, floor or platform & the maximum height to the top of the inverter is 2 meters

Get Price

Ground mounted solar

Ground mounted solar Image credit: LUC Brief description of technology Solar PV arrays commonly comprise of a number of solar panels, each typically 0.5 to

Get Price

This is a General Guide for Photovoltaic Plans Submittal

Show the entire PV system including modules, junction, combiner boxes, wires and conduits and sizes, conductors-type and sizes, inverters, AC/DC disconnects and type, and main electrical

Get Price

Requirements for Mounting the Inverter

For roof mounting, the clearance from the inverter to the bottom side of the PV module must be at least 30 mm (1.2 in). This will prevent the grounding bolt from damaging the PV module.

Get Price

Installation Requirements

Yes -the maximum height to the top of the inverter is 2 metres above ground, floor or platform, the minimum height to the bottom of the inverter shall not be less than 500mm from ground, floor

Get Price

Photovoltaic inverter installation height from ground

They use photovoltaic (PV) technology to turn sunlight into direct current (DC) electricity which is then converted by a solar inverter into an alternating current (AC) that can be used to power

Get Price

Photovoltaic inverter mounting height | Information by Electrical

That switch is required to be less than two meters (6''-7") high (see 404.8) unless there is another switch that meets the requirements of 690.14 (C) (1). A second issue is that

Get Price

Where do I put my solar inverter?

The maximum height to the top of the inverter is 2 meters above ground – and this is simply for reasons of future access. While quality inverters should last a

Get Price

Photovoltaic inverter grounding tips

What is effective grounding in photovoltaic (PV) systems? Effective grounding in photovoltaic (PV) systems is the creation of a low-impedance reference to ground at the AC side of the inverter-

Get Price

Installing grid connected photovoltaic systems in the ACT

The maximum height to the top of the inverter is 2m above ground, floor or platform, the minimum height to the botom of the inverter shall not be less than 500mm from ground, loor or platform.

Get Price

Clearance Guidelines for Mounting Three Phase Inverters

If a metal back sheet is used under conditions of direct sunlight, it is recommended to leave 30 cm of clearance between the sheet and the inverter. A clearance of under 30 cm may cause the

Get Price

Guidelines for the operation and maintenance of rooftop solar

The Guidelines have been produced by members of Solar Energy UK''s Rooftop O&M Working Group. They discuss issues which are relevant to maintaining the condition and efficiency of

Get Price

Where do I put my solar inverter?

The maximum height to the top of the inverter is 2 meters above ground – and this is simply for reasons of future access. While quality inverters should last a long time (Crappy ones have

Get Price

6 FAQs about [Height of photovoltaic inverter from the ground]

How high should an inverter be?

Yes -the maximum height to the top of the inverter is 2 metres above ground, floor or platform, the minimum height to the bottom of the inverter shall not be less than 500mm from ground, floor or platform. Do I need to provide isolation for the AC circuit at or near the inverter?

What is the minimum clearance between inverter and PV module?

Observe recommended clearances to the inverters or other objects. Minimum Clearance between Inverter and PV Module Bottom Side: For roof mounting, the clearance from the inverter to the bottom side of the PV module must be at least 30 mm (1.2 in). This will prevent the grounding bolt from damaging the PV module.

How to mount a solar inverter on a roof?

For roof mounting, the clearance from the inverter to the bottom side of the PV module must be at least 30 mm (1.2 in). This will prevent the grounding bolt from damaging the PV module. Permitted Mounting Position: During mounting, make sure that the connection area of the inverter remains dry.

Where should a PV inverter be mounted?

When mounting on the framework, the mounting position should preferably be in the center of the PV module. This will ensure a longer electrical endurance of the inverter. Greater distances between two inverters can be bridged using an additional cable and two AC field plugs ( > Assembling the AC Field Plug).

Where is a safe location for a solar inverter?

A safe location can either be a garage or a basement, where you can easily connect your inverter to the local grid. As per ESV.vic.gov.au, the minimum height to the bottom of the inverter can’t be less than 500mm from the ground, floor or platform & the maximum height to the top of the inverter is 2 meters above ground, floor, or platform.

What temperature should a solar inverter be installed at?

Observe the warning messages on the inverter. To ensure optimum operation, the ambient temperature should be between -40°C (-40°F) and 65°C (-149°F). The mounting location should not be exposed to direct solar irradiation. Direct solar irradiation can cause the inverter to overheat. As a result, the inverter reduces its power output.

More related information

-

Photovoltaic inverter installation height

Photovoltaic inverter installation height

-

How much does a photovoltaic inverter cost at present

How much does a photovoltaic inverter cost at present

-

Huawei photovoltaic inverter sales

Huawei photovoltaic inverter sales

-

Photovoltaic on-grid and off-grid inverter

Photovoltaic on-grid and off-grid inverter

-

Which is better an inverter or a photovoltaic cell

Which is better an inverter or a photovoltaic cell

-

Inverter photovoltaic parameters various specifications

Inverter photovoltaic parameters various specifications

-

DC remote photovoltaic inverter

DC remote photovoltaic inverter

-

Photovoltaic inverter inspection

Photovoltaic inverter inspection

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.