SolarEdge

SolarEdge - Single string design guidelines - Application note – North America This application note establishes guidelines for implementing the single string design topology in North

Get Price

Solar System Design – String Sizing

Based on these numbers, if a solar inverter with a minimum voltage of 200V were considered, a string of 7 would fail under hot operating

Get Price

What Size Solar Inverter Do I Need? Experts Break It Down

What Size Solar Inverter Do I Need? A solar inverter should closely match your solar system''s output in kW—typically within 80% to 120% of your total panel capacity.

Get Price

Solar Inverter String Design Calculations

Solar Inverter String Design Calculations The following article will help you calculate the maximum / minimum number of modules per series string when designing your PV system. And the

Get Price

SolarEdge System Design and the NEC

Maximum (STC) power per string, and minimum and maximum string lengths. This document explains how these values are determined and provides the string sizing rules for the different

Get Price

Solar Inverter Size Chart

Solar panels produce DC electricity, but you need an inverter to convert DC power into 120/220 volt AC electricity, Only after conversion can home appliances and other devices use it. I f you

Get Price

How to Calculate PV String Size — Mayfield Renewables

When designing a solar PV system it''s critical to know the minimum and maximum number of PV modules that can be connected in series, referred to as a string. PV modules

Get Price

When choosing an inverter, what voltage ratings should you pay

Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the inverter needs to begin functioning.

Get Price

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

The inverter shall include appropriate self-protective and self-diagnostic feature to protect itself and the PV array from damage in the event of inverter component failure or from parameters

Get Price

Everything You Need to Know about Hybrid Solar

How hybrid solar inverters work in modern energy systems? Follow this guide, we will explore what the benefits of hybrid inverters are and what

Get Price

How to Calculate PV String Size — Mayfield Renewables

Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power. This is

Get Price

When choosing an inverter, what voltage ratings

Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the

Get Price

How To Read And Interpret An Inverter Specification

Inverter specifications are technical information that describes an inverter''s capabilities, characteristics, and limitations. They guide users in choosing an

Get Price

A Guide To Solar Inverter Sizing

To calculate the inverter size in KVA, we need to apply the following calculation: KVA = KW / Power factor (constant at 0.8 for homes) = 1.05 / 0.8. = 1.31.

Get Price

Solar Inverter String Design Calculations

The following article will help you calculate the maximum / minimum number of modules per series string when designing your PV system. And the inverter sizing comprises two parts,

Get Price

Minimum Voltage Questions : r/SolarDIY

I ask because it looks like I''ll need a minimum of like 5 200W panels or more. My brother has a similar charger/inverter with a minimum voltage of 125V, and he has WAY less than that - like

Get Price

Voc, Vmp, Inverter startup voltage | DIY Solar Power Forum

You must just match your panel setup to meet the minimum start up voltage of the Inverter/MPPT. You can do that by adding more panels in series or using panels with higher

Get Price

Technical White Paper SolarEdge Single Phase Inverter

Page 1 of 10 Introduction The SolarEdge Distributed Energy Harvesting System is a state-of-the-art system designed to harvest the maximum possible energy from photovoltaic (PV) modules

Get Price

Minimum specifications for photovoltaic inverters

Solar inverter specifications are crucial for optimizing the performance of your solar panel system. Input specifications include maximum DC input voltage, MPPT voltage range, maximum DC

Get Price

If the minimum start up voltage of an inverter is 60v, which

Your inverter should have a bunch of stats, example: Min. startup: 60v. MPPT range: 100 - 250v. Maximum input voltage: 275v. This means that if the voltage it gets from the panels is under

Get Price

A Guide To Solar Inverter Sizing

To calculate the inverter size in KVA, we need to apply the following calculation: KVA = KW / Power factor (constant at 0.8 for homes) = 1.05 / 0.8. = 1.31. Make sure to use the continuous

Get Price

How To Size A Solar Inverter in 3 Easy Steps

What size solar inverter should you use for your system? In this guide we share how to correctly size a solar inverter in 3 steps.

Get Price

Calculations for a Grid-Connected Solar Energy System

The grid-connected system consists of a solar photovoltaic array mounted on a racking system (such as a roof-mount, pole mount, or ground mount), connected to a combiner box, and a

Get Price

What Size Solar Inverter Do I Need? A Quick Sizing Guide

Learn what size solar inverter do I need with step-by-step load calculations, surge tips, and Lefor Solar Inverter Series recommendations.

Get Price

Inverter Specifications and Data Sheet

Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power. This is the maximum power the inverter

Get Price

How to Read Solar Inverter Specifications

We must check the current range of the solar panel and make sure it does not exceed the maximum range to avoid overloading the inverter. The start-up voltage is the

Get Price

If the minimum start up voltage of an inverter is 60v, which

Your inverter should have a bunch of stats, example: Min. startup: 60v. MPPT range: 100 - 250v. Maximum input voltage: 275v. This means that if the voltage it gets from the

Get Price

What Size Solar Inverter Do I Need? A Quick Sizing

Learn what size solar inverter do I need with step-by-step load calculations, surge tips, and Lefor Solar Inverter Series recommendations.

Get Price

What Size Solar Inverter Do I Need? Experts Break It

What Size Solar Inverter Do I Need? A solar inverter should closely match your solar system''s output in kW—typically within 80% to 120% of your

Get Price

6 FAQs about [Solar inverter minimum]

What is a maximum input voltage in a solar inverter?

The maximum input voltage defines the highest voltage the inverter can safely accept without causing damage. [Maximum input voltage] (Maximum input voltage in solar inverters) 2 indicates the upper voltage limit an inverter can handle. It’s crucial for ensuring long-term durability.

How much voltage can a solar inverter handle?

As solar technology improves, panels often produce higher voltages, so it's important to select an inverter that can handle these surges, especially during periods of peak sunlight. Typically, residential inverters have a maximum input voltage between 500V and 1000V.

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

What size solar inverter do I Need?

Recommended Inverter Size: 1,200 W minimum. If you later add an air conditioner (2,400 W surge), you’d bump up to a 3,000 W inverter—like the Lefor 3000W in the Lefor Solar Inverter Series. Appliances: LED lighting (4 × 10 W), mini-fridge (150 W), laptop (60 W), water pump (300 W surge). Final Size: 660 W → Round up to a 1,000 W inverter.

Do you need a solar inverter?

The inverter is one of the most important components of a home or portable solar power system. Solar panels produce DC electricity, but you need an inverter to convert DC power into 120/220 volt AC electricity, Only after conversion can home appliances and other devices use it.

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

More related information

-

How many gears should the solar water pump inverter be set to

How many gears should the solar water pump inverter be set to

-

Heishan Solar Water Pump Inverter Customized Manufacturer

Heishan Solar Water Pump Inverter Customized Manufacturer

-

Solar inverter uses electricity at the same time

Solar inverter uses electricity at the same time

-

Latvian solar water pump inverter equipment

Latvian solar water pump inverter equipment

-

Solar Irrigation Farmland Water Pump Inverter

Solar Irrigation Farmland Water Pump Inverter

-

Solar Water Pump Inverter 550w

Solar Water Pump Inverter 550w

-

How much power does a solar water pump inverter usually have

How much power does a solar water pump inverter usually have

-

Outdoor solar water pump inverter recommendation

Outdoor solar water pump inverter recommendation

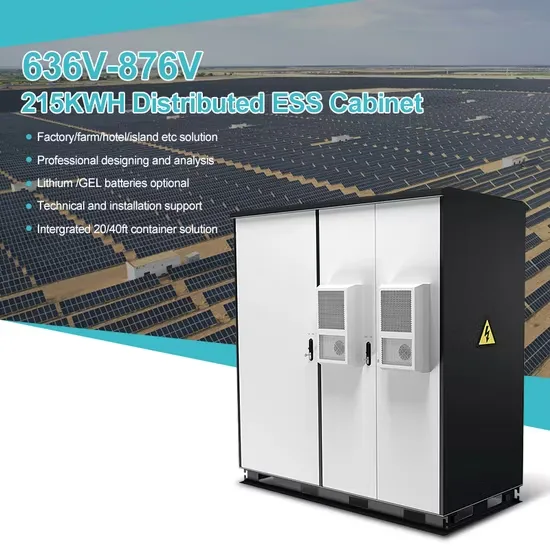

Commercial & Industrial Solar Storage Market Growth

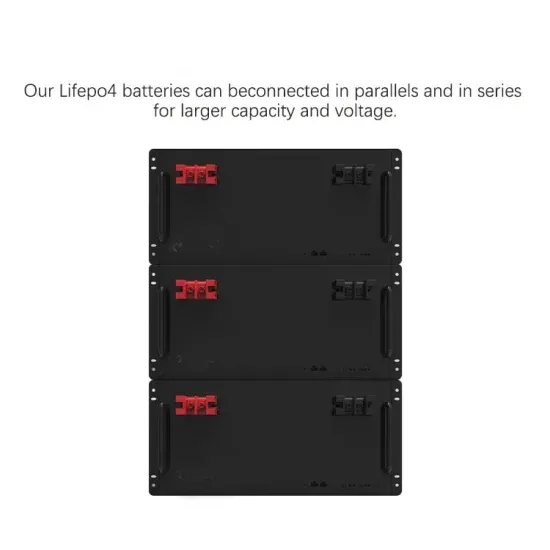

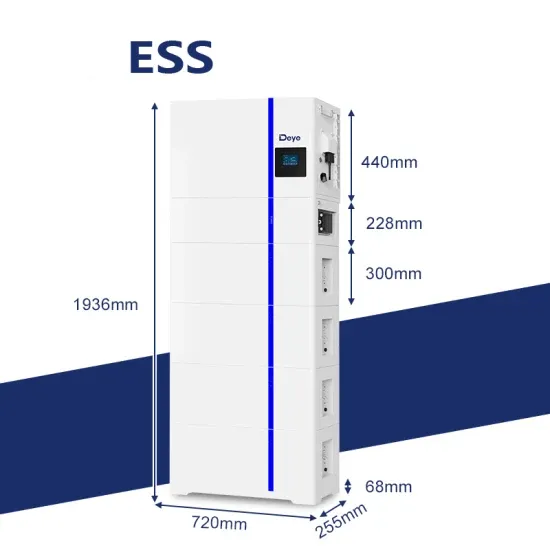

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.