Battery Pack Assembly Bill of Process

A generic battery pack assembly bill of process that lays out the high level steps and challenges. In this process we are going from incoming

Get Price

Battery assembly solution

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly,

Get Price

EV Battery Manufacturing

Rockwell Automation understands the commercial and technical requirements for both EV makers and related machine builders to drive integration and create differentiation throughout the

Get Price

Optimize Battery Assembly Line with Design and Automation

Discover the key features of a modern battery pack assembly line and how expert design and automation can boost performance, flexibility and output.

Get Price

Energy storage cabinet assembly automation design

For the battery and energy storage industry, our solutions combined with powerful inspection features provide efficient, reliable and quick testing and assembly automation.

Get Price

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now

Get Price

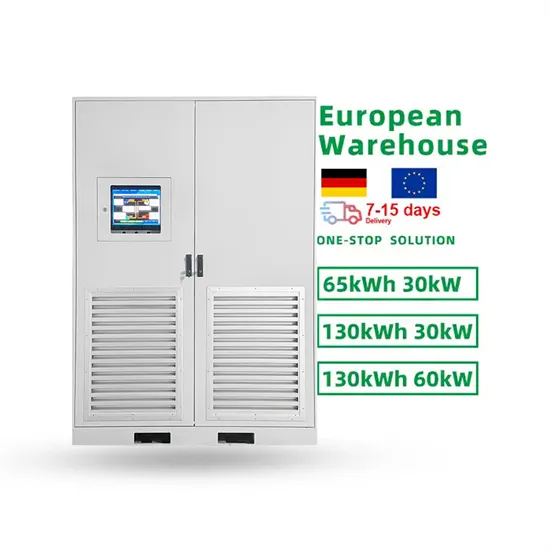

Battery Storage Cabinet

Battery energy storage cabinets are widely applied in various critical scenarios, including backup power supply for telecom base stations, energy regulation in industrial automation systems,

Get Price

Automation solutions for battery production

Festo meets these requirements with a wide range of standard pneumatics, electric automation and process automation. On the following pages you will find selected examples for individual

Get Price

Battery assembly solution

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and

Get Price

Technical Specification for LV Automation applied to LV

SCOPE This document defines the technical and functional requirements of the LV Automation and protection deployed in LV Engine project. This document covers the controllable circuit

Get Price

Standard Panels Technical Data

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by suitably trained personnel in accordance with

Get Price

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Get Price

In-Depth Overview of Battery Cell Assembly Processes

Thorough knowledge of battery cell assembly is imperative for driving innovations in storage technology and addressing emerging energy demands. Prologue to

Get Price

1756 ControlLogix Chassis Specifications

The ControlLogix® system is a modular system that requires a 1756 ControlLogix chassis. The chassis are designed for only horizontal back-panel mounting. Place any module into any slot.

Get Price

Automated battery assembly lines | Mondragon Assembly

Modular and scalable battery assembly automation solutions. Turnkey projects to design the line that best fits your production volumes.

Get Price

EV BATTERY PACK MANUFACTURING

These systems, which are used to store, sort, and pick the battery packs when needed, may be best automated with the use of a large 6-axis robot and a 7th-axis linear positioner that can

Get Price

Fully Automated Battery Manufacturing

Development of flexible, high-throughput battery manufacturing line using advanced conveyance/motion control, precision web handling, and assembly.

Get Price

Guideline: optimizing battery manufacturing automation | Balluff

In this guide, we cover each step of the manufacturing process, providing detailed insights and practical examples of how automation components can optimize each step, from electrode

Get Price

Power Conversion System for ESS 100 kW to 30 MW Bi

Power Conversion Systems With more than 125 years experience in power engineering and over a decade of expertise in developing energy storage technologies, ABB is a pioneer and leader

Get Price

EV Battery Production. Optimized.

To improve operations, the Rockwell Automation MES for battery But that''s not all. The integrated solution also expands to module and production seamlessly manages and tracks your

Get Price

Automation of Operations in Assembly of Battery Modules in

This paper provides proposals for potential applications where deployment of robotic automation in the battery module assembly context can be explored. The paper investigates

Get Price

Home | Bosch Manufacturing Solutions | BMG

As a global industrialization partner and turnkey special machinery provider for production equipment and automation, we offer customized assembly and

Get Price

Meeting Aggressive Timelines in Battery Manufacturing

Challenge Designing and building a new automated assembly system for cylindrical battery cell production. Meeting strict government funding deadlines that demanded

Get Price

Mastering the Battery Pack Assembly Process: A

For manufacturers and engineers looking to optimize their battery pack assembly processes, investing in advanced technologies and automation

Get Price

Mastering the Battery Pack Assembly Process: A Comprehensive

For manufacturers and engineers looking to optimize their battery pack assembly processes, investing in advanced technologies and automation is key. Explore our range of

Get Price

6 FAQs about [Technical requirements for battery cabinet assembly automation]

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is a battery pack assembly process?

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

Why is quality control important in battery pack assembly?

Quality control is paramount in battery pack assembly to prevent defects and ensure safety. Key measures include: Visual Inspections: Checking for physical defects like damaged cells or faulty wiring. Functional Testing: Verifying electrical properties such as voltage, capacity, and charging cycles.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

How can Rockwell Automation help your EV battery manufacturing?

ss Every Step of the WayRockwell Automation can help you solve your EV battery manufacturing challenges so you can streamline your production line and get the best value for ICT an

More related information

-

Battery cabinet customization technical requirements

Battery cabinet customization technical requirements

-

Solid-state battery cabinet technical parameters

Solid-state battery cabinet technical parameters

-

New Energy Battery Cabinet Assembly Site

New Energy Battery Cabinet Assembly Site

-

What are the requirements for battery cabinet installation

What are the requirements for battery cabinet installation

-

New energy battery cabinet automation equipment

New energy battery cabinet automation equipment

-

Battery cabinet requirements for distribution rooms

Battery cabinet requirements for distribution rooms

-

Cook Islands Energy Storage Cabinet Battery Assembly

Cook Islands Energy Storage Cabinet Battery Assembly

-

Egypt energy storage cabinet battery assembly

Egypt energy storage cabinet battery assembly

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.