IR N-3: Modular Battery Energy Storage Systems

PURPOSE This Interpretation of Regulations (IR) clarifies specific code requirements relating to battery energy storage systems (BESS) consisting of prefabricated modular structures not on

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or cabinet is always a

Get Price

IR N-4: Modular Battery Energy Storage Systems: 2022 CBC

PURPOSE This Interpretation of Regulations (IR) clarifies specific code requirements relating to battery energy storage systems (BESS) consisting of prefabricated modular structures not on

Get Price

Choosing the Right Lithium Ion Battery Cabinet: A

Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Get Price

Lithium Battery Charging Cabinet: The Essential Guide to Safe

Discover how a lithium battery charging cabinet enhances safety by preventing fires, controlling temperature, and offering secure storage. Learn the benefits, features, and

Get Price

New UL Standard Published: UL 1487, Battery Containment

Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL Standards and

Get Price

Energy Storage Battery Pack Enclosure size optimization and

Learn about the industry-leading ESS Battery Enclosure specifications and efficient layout strategies of CATL, BYD, etc., to improve system space utilization and reliability.

Get Price

Charging and storage area | CEMO

A small cabinet size is therefore also completely in the spirit of what the fire brigade would prefer. That said, there is no need to forego flexible storage in

Get Price

Practical considerations when designing a battery room

In this post I will gather in a succinct way some recommendations on these three aspects. I even encourage you to use it as a basic checklist (not to replace for a professional

Get Price

Designing Industrial Battery Rooms: Fundamentals and Standards

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

Get Price

Best Practices for Design of Enclosures with Batteries

Careful design and placement are required in order to reduce susceptibility to shock and vibration. Mechanical structures can be attached to

Get Price

Best Practices for Design of Enclosures with Batteries

Careful design and placement are required in order to reduce susceptibility to shock and vibration. Mechanical structures can be attached to strategic locations on a board to

Get Price

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get Price

480.9 Battery Locations.

Code Change Summary: Many new requirements were added for battery locations in 480.9. As battery technology changes, so does the need to modify the rules pertaining to batteries in the

Get Price

Choosing the Right Battery Storage Cabinet: A Comprehensive

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using lithium-ion battery storage

Get Price

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Cabinet design, by contrast, must address the problem of removing heat as well as any off-gassing from the battery. Cabinet-mounted VRLA batteries can be expected to operate in a

Get Price

UPS Room Requirements & Cooling Guide | SecurePower

A UPS requires a stable environment to operate efficiently and prolong battery life. Key considerations include: Ventilation: Ensure adequate airflow to prevent overheating. UPS units

Get Price

Requirements for battery enclosures – Design considerations

When designing e-mobiles - and thus the batteries or battery cases - there are some basic requirements that have to be taken into account, both from the technology as well as from

Get Price

Stationary Storage Battery Systems | UpCodes

Stationary storage battery systems shall comply with the seismic design requirements in Chapter 16 and shall not exceed the floor-loading limitation of the building.

Get Price

The Ultimate Guide to Lithium-Ion Battery Storage

Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and

Get Price

How to design an energy storage cabinet: integration and

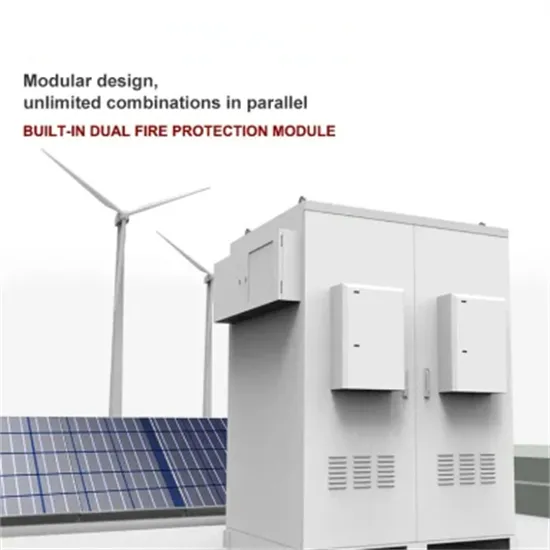

The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

Get Price

Considerations For Battery Room Design, Battery Stands and

Batteries may be mounted on racks or in cabinets. When installed on racks, these may be of wood or steel and both may be insulated from earth. Generally speaking, battery stands are

Get Price

NEW YORK CITY FIRE DEPARTMENT

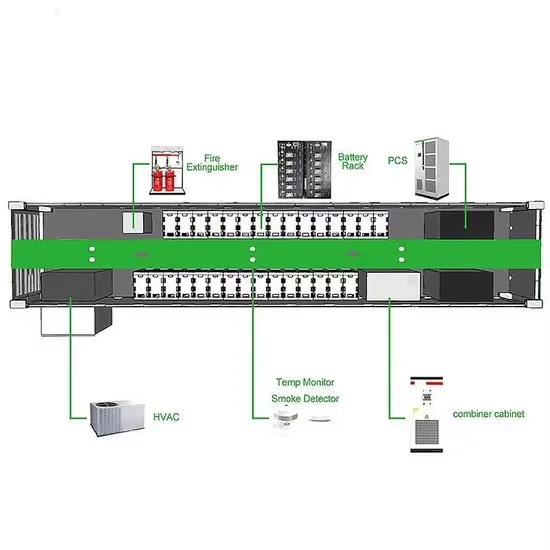

Background and Purpose ary storage battery systems. This rule implements those guidelines through fully-developed design and installation requirements and emergency management

Get Price

Designing Ventilation For Battery Rooms | 2018-05-07

Battery rooms or stationary storage battery systems (SSBS) have code requirements such as fire-rated enclosure, operation and maintenance

Get Price

Complete Guide for Battery Enclosure

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using

Get Price

6 FAQs about [Battery cabinet design requirements]

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

What rating should a battery cabinet have?

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating. It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure. Indoor Battery Box Enclosure 2. Mounting Mechanism for Battery Cabinet

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

More related information

-

Battery Cabinet Requirements

Battery Cabinet Requirements

-

Battery cabinet waterproof design solution

Battery cabinet waterproof design solution

-

Power design of battery energy storage cabinet

Power design of battery energy storage cabinet

-

Battery cabinet customization technical requirements

Battery cabinet customization technical requirements

-

Square battery energy storage cabinet design

Square battery energy storage cabinet design

-

Design of outdoor power battery cabinet

Design of outdoor power battery cabinet

-

Battery cabinet quality requirements

Battery cabinet quality requirements

-

Outdoor battery cabinet design elements

Outdoor battery cabinet design elements

Commercial & Industrial Solar Storage Market Growth

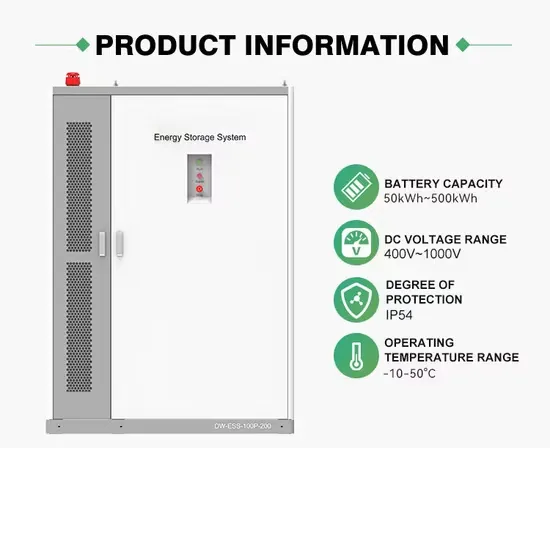

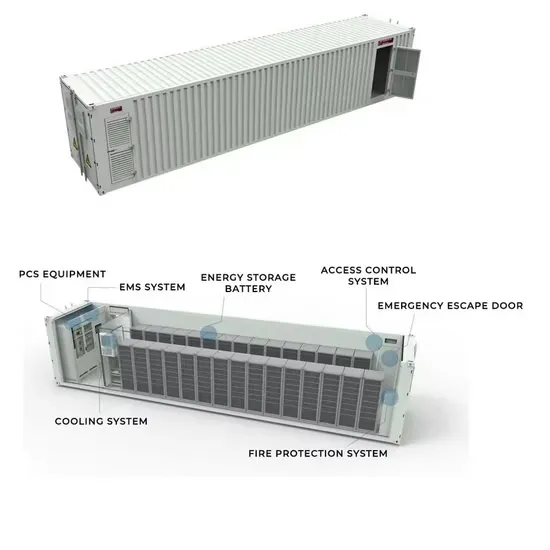

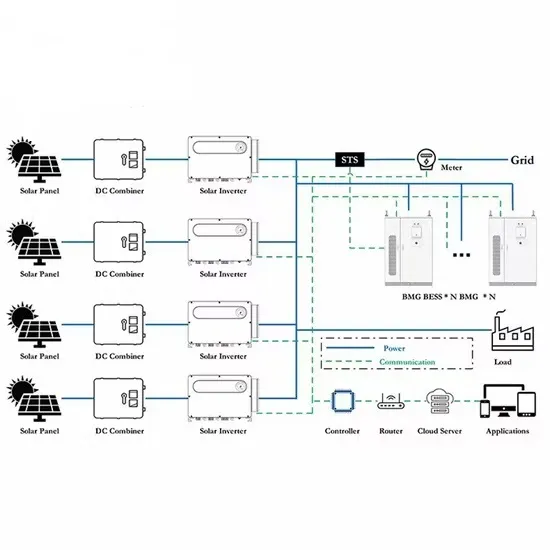

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

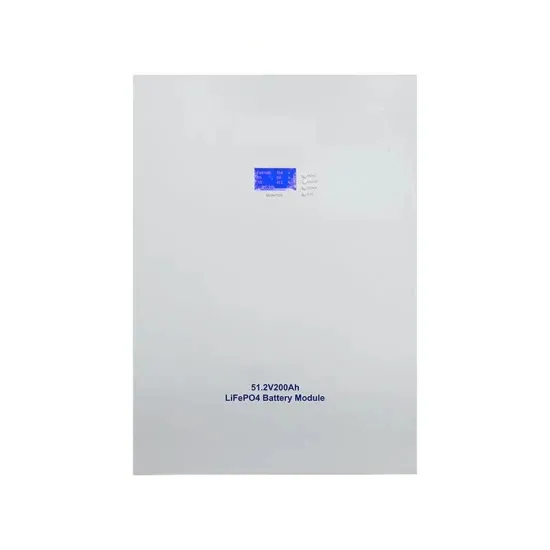

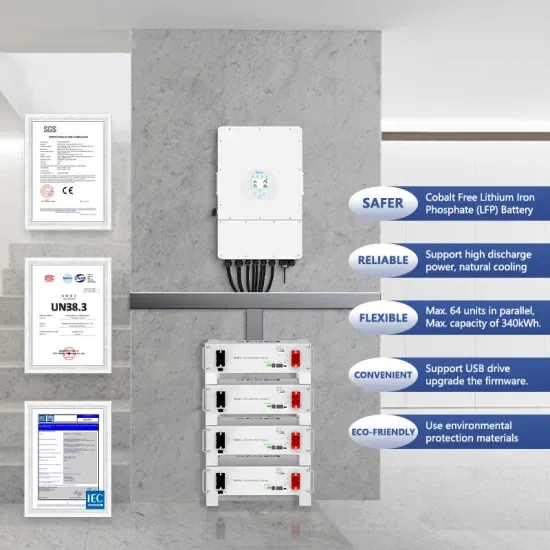

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.