Cadmium Telluride Solar Panels Vs. Silicon:

The most significant difference between silicon and CdTe solar panels lies in their material composition and manufacturing processes. While

Get Price

What Is Polysilicon and What Is It Used For? | WaferPro

WaferPro 0 Polysilicon, also known as polycrystalline silicon or simply poly-Si, is a core material that serves as the backbone of various vital technologies that empower the

Get Price

P-Type & N-Type Solar Panel: What Are the Differences

A notable distinction between n-type and p-type solar cells lies in the type of crystalline silicon (c-Si) wafers constituting the bulk region and those forming

Get Price

Solar Cell Production: from silicon wafer to cell

It is essential to distinguish between the varying types of silicon wafers, as each type holds unique characteristics that affect their application

Get Price

The main differences between N-type and P-type

Monocrystalline silicon wafers have the physical properties of quasi-metals, with weak conductivity, and their conductivity increases with

Get Price

Solar Wafer

What is a Solar Wafer? A solar wafer is a thin slice of a crystalline silicon (semiconductor), which works as a substrate for microeconomic devices for fabricating

Get Price

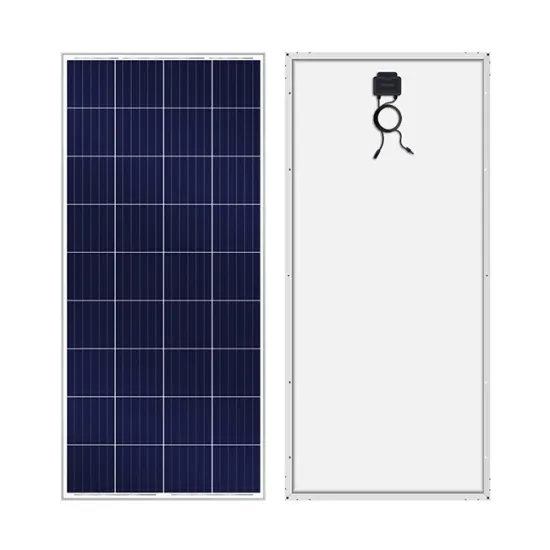

Monocrystalline vs. Polycrystalline Solar Panels

Learn the differences between monocrystalline and polycrystalline solar panels, including efficiency, cost, and suitability for various applications.

Get Price

Mono vs Polycrystalline Solar cells

By contrast, a polycrystalline silicon wafer is made by melting the silicon feed stock, pouring it into a cube shaped mould and letting it cool and

Get Price

Monocrystalline vs. polycrystalline solar panels

The main difference between monocrystalline and polycrystalline solar panels is efficiency — monocrystalline are more efficient. Read more

Get Price

Solar Wafer

What is a Solar Wafer? A solar wafer is a thin slice of a crystalline silicon (semiconductor), which works as a substrate for microeconomic

Get Price

What are solar silicon wafers like? | NenPower

The average lifespan of solar silicon wafers significantly contributes to the overall longevity of solar power systems. Typically, solar

Get Price

What is the difference between silicon wafers in electronics and

Silicon wafers in solar cells are 100–200 mm in diameter and 200-300 μm in thickness. Anti-reflection coatings are applied to increase the amount of light coupled into the

Get Price

Solar Silicon Wafers as-cut wafers high-quality-low-price

Our analysis suggests that the p-types of SHj solar cells should be at least twice as efficient as their n-types. This work represents a new approach to the

Get Price

The main differences between N-type and P-type monocrystalline silicon

Monocrystalline silicon wafers have the physical properties of quasi-metals, with weak conductivity, and their conductivity increases with increasing temperature. They also

Get Price

Silicon Wafers: Powering Solar Cells

Solar cells are electrical devices that convert light energy into electricity. Various types of wafers can be used to make solar cells, but silicon wafers are the

Get Price

Solar Wafers: The Building Blocks of Photovoltaic

Solar wafers are crucial for this clean energy option. They are made of monocrystalline or polycrystalline silicon. This makes up 95% of today''s

Get Price

A Detailed Guide about Solar Wafers: Application And Types

Did you know the core components of solar cells comprise solar wafers? Yes, you read that right! More than half of the utilized pure silicon gets processed to produce solar

Get Price

N-Type vs. P-Type Solar Panels: An In-Depth to Both

We''ll explain the differences between N-type and P-type solar panels, their pros and cons, as well as their market share in the future.

Get Price

A Detailed Guide about Solar Wafers: Application And

Did you know the core components of solar cells comprise solar wafers? Yes, you read that right! More than half of the utilized pure silicon gets

Get Price

What Is a Silicon Wafer for Solar Cells?

Silicon is found everywhere — it''s the second most abundant element on Earth. But, the pure silicon crystals required to make solar-grade wafers are very different from sand on the beach.

Get Price

Mono PERC vs Monocrystalline Solar Panels: An In-Depth

Discover the key differences between Mono PERC vs Monocrystalline solar panels, including efficiency comparisons, cost implications, and performance in various conditions.

Get Price

The difference between thin film and crystalline silicon

Moreover, the solar energy absorption factor is very low, and the material is brittle and fragile. Thin-film solar cells are cheaper than old

Get Price

Solar Cells Comparison

There are 3 types of solar panels on the market, and in this informational guide, let''s break down the difference among amorphous, monocrystalline, and

Get Price

Monocrystalline Vs Polycrystalline Solar Panels 2025: A

Compare monocrystalline solar panels vs polycrystalline solar panels to determine the best choice for your solar energy needs. Learn about their differences, pros, and cons, and find the ideal

Get Price

What does solar silicon wafer mean? | NenPower

It is essential to distinguish between the varying types of silicon wafers, as each type holds unique characteristics that affect their application in solar technology. Monocrystalline

Get Price

The difference between silicon wafers and solar cells

e solar cells are initially made from silicon wafers. A monocrystalline solar cell is made from a single crystal of the element silicon. On the other hand, polycrystalline silicon solar cells are

Get Price

Solar Silicon Wafers as-cut wafers high-quality-low-price

Our analysis suggests that the p-types of SHj solar cells should be at least twice as efficient as their n-types. This work represents a new approach to the production of SH-Joules per square

Get Price

Solar Wafers: The Building Blocks of Photovoltaic Technology

Solar wafers are crucial for this clean energy option. They are made of monocrystalline or polycrystalline silicon. This makes up 95% of today''s solar panel market.

Get Price

Solar Cell Production: from silicon wafer to cell

This article explains in detail the production process from sliced silicon wafer disks to the final ready-to-assemble solar cell.

Get Price

More related information

-

Are there any differences in solar panels

Are there any differences in solar panels

-

Monocrystalline silicon on solar photovoltaic panels

Monocrystalline silicon on solar photovoltaic panels

-

Silicon in solar panels

Silicon in solar panels

-

Photovoltaic silicon solar panels

Photovoltaic silicon solar panels

-

Middle East crystalline silicon photovoltaic modules solar panels

Middle East crystalline silicon photovoltaic modules solar panels

-

Differences between solar panels and photovoltaic curtain walls

Differences between solar panels and photovoltaic curtain walls

-

What are the differences between solar panels of different wattages

What are the differences between solar panels of different wattages

-

Austrian crystalline silicon photovoltaic solar panels

Austrian crystalline silicon photovoltaic solar panels

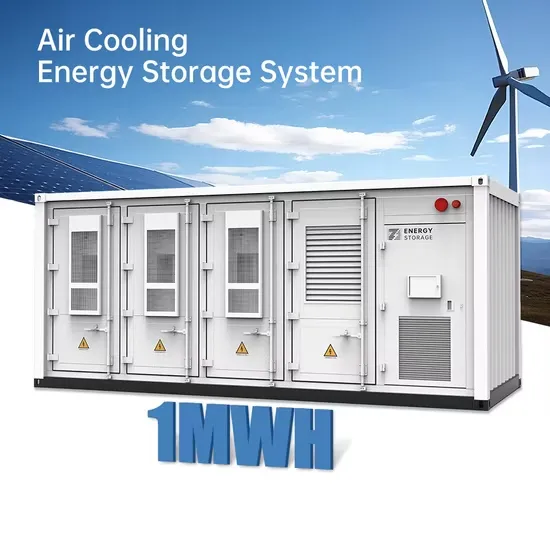

Commercial & Industrial Solar Storage Market Growth

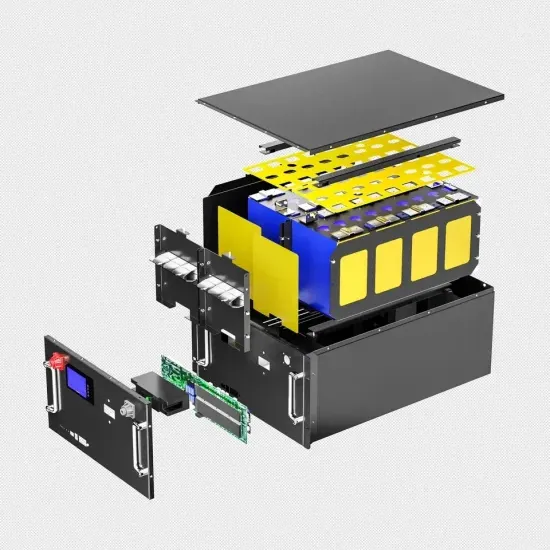

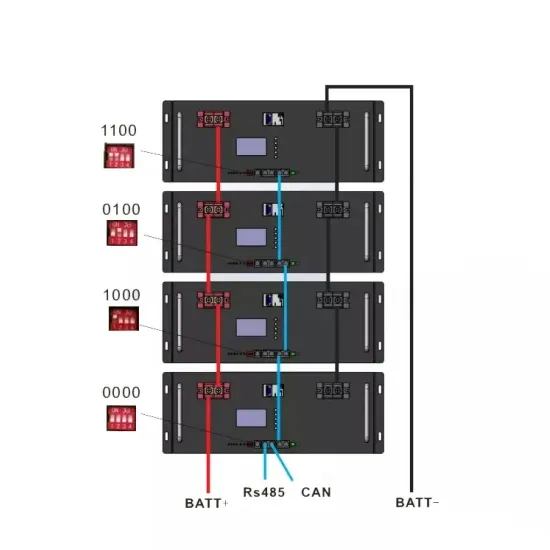

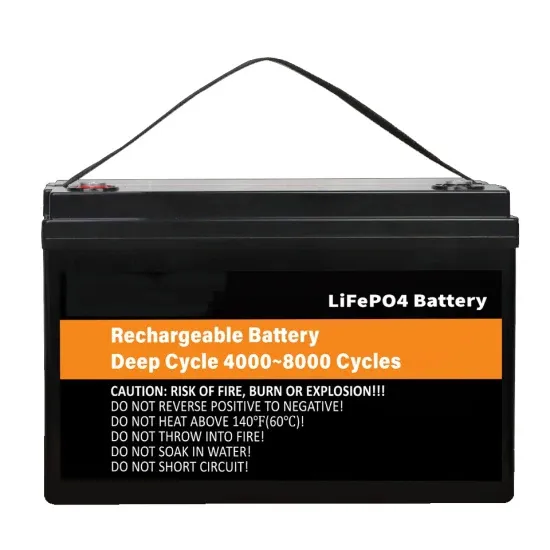

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.