Interfacial Challenges, processing strategies, and composite

Conventional lithium−ion batteries use flammable liquid electrolytes may increase the risk of spontaneous combustion and explosion. The emergence of a

Get Price

Kosmotropic aqueous processing solution for green lithium battery

Current lithium-ion battery cathode production relies on toxic solvents, raising another environmental concern. Here, authors present a kosmotropic aqueous processing

Get Price

Lithium-Ion Batteries: The Future of Energy Storage and

Lithium-ion batteries are reshaping the energy landscape, fueling the growth of electric vehicles and renewable energy storage. However, their storage and handling require specialized

Get Price

Lithium-Ion Battery Manufacturing: Industrial View on

1. Introduction Lithium-ion batteries (LIBs) attract considerable interest as an energy storage solution in various applications, including e

Get Price

High-throughput and high-performance lithium-ion batteries via

Lithium-ion batteries (LIBs) have been playing an essential role in energy storage and empowering electric vehicles (EVs) by alleviating the CO 2 emission from the fossil fuel

Get Price

Taking battery manufacturing to the next level

To meet this demand, battery manufacturing needs to be faster, cheaper, more dependable, less energy-intensive and less wasteful. A key part of lithium-ion battery

Get Price

Fire Spread Risks Underground: Passive Protection Saves Lives

Learn how a fire barrier protects lithium-ion battery storage from thermal runaway and compare fire barriers vs. firewalls for high-risk energy facilities.

Get Price

Current and future lithium-ion battery manufacturing

In this perspective paper, we first evaluate each step of the current manufacturing process and analyze their contributions in cost, energy consumption, and

Get Price

PFAS-Free Energy Storage: Investigating Alternatives

The class-wide restriction proposal on perfluoroalkyl and polyfluoroalkyl substances (PFAS) in the European Union is expected to affect

Get Price

Africa''s lithium rush: How Nigeria can become a

In recent years, the global demand for lithium—a critical component in rechargeable batteries—has surged, driven by the rapid

Get Price

Energy Storage & Conversion Manufacturing

Enhancing precision processing and fabrication of solid-state batteries in large format cells. Verification and validation (V&V) of solid-state battery scalability. Manufacturing for new (or

Get Price

Advanced electrode processing for lithium-ion battery

In this Review, we discuss advanced electrode processing routes (dry processing, radiation curing processing, advanced wet processing and 3D-printing processing) that could

Get Price

From Materials to Cell: State-of-the-Art and

In this Review, we outline each step in the electrode processing of lithium-ion batteries from materials to cell assembly, summarize the recent

Get Price

Current and future lithium-ion battery manufacturing

In this perspective paper, we first evaluate each step of the current manufacturing process and analyze their contributions in cost, energy consumption, and throughput impacts for the entire

Get Price

Advanced battery electrode processing technologies show

Numerous market analyses have shown that over the next five years, demand for lithium-ion batteries for everything from personal electric devices to grid-scale energy storage

Get Price

From Materials to Cell: State-of-the-Art and Prospective

In this Review, we outline each step in the electrode processing of lithium-ion batteries from materials to cell assembly, summarize the recent progress in individual steps,

Get Price

Comparative techno-economic assessment of integrated PV

A comparative investigation based on two case studies is presented in this paper for a natural gas processing plant; an integration of Photovoltaic panels with Battery Energy

Get Price

Lithium-Ion Batteries: Mineral Processing, Applications, Recycling

Technologies to store energy rely on mineral processing to refine the materials needed to power many modern devices, buildings, and even cities. Lithium is extracted from

Get Price

Electrode manufacturing for lithium-ion batteries—Analysis of

As modern energy storage needs become more demanding, the manufacturing of lithium-ion batteries (LIBs) represents a sizable area of growth of the technology. Specifically,

Get Price

Tesla''s First US Lithium Refinery Making Progress in Texas

Why a Lithium Refinery Matters Lithium is a critical component of lithium-ion batteries, the powerhouse behind electric vehicles, solar storage systems, and countless other

Get Price

Sustainable Lithium Extraction: How is Lithium Mined

Discover sustainable lithium extraction methods and how lithium is mined and processed for electric vehicle battery production. Explore

Get Price

Understanding the Lithium-Ion Battery Manufacturing Process

Renewable Energy Storage: As society moves towards harnessing solar and wind energy, lithium-ion batteries are integral in storing this energy for later use. They help stabilize the grid by

Get Price

3D Printing Lithium-Ion Batteries: Architectures and Gains

3 days ago· Lithium-ion batteries are the workhorse of modern energy storage, powering everything from handheld electronics to electric vehicles. Yet behind their sleek performance

Get Price

Thermal Processing of Lithium-Ion Minerals | Heyl Patterson

3 days ago· Optimizing Lithium-Ion Battery Material Production with Thermal Processing As demand for lithium-ion batteries has surged, so too has demand for lithium-ion minerals. The

Get Price

Energy Storage Manufacturing | Advanced Manufacturing Research | NREL

NREL''s novel roll-to-roll laser-processing methods improve the performance of energy storage materials and manufacturing. NREL''s on-site laser ablation capabilities

Get Price

Energy Storage & Conversion Manufacturing

fundamental issues of materials and electrochemical interactions associated with lithium and beyond-lithium batteries. Supports applied R&Ds that focus on optimizing next generation,

Get Price

Energy Storage Manufacturing | Advanced

NREL''s novel roll-to-roll laser-processing methods improve the performance of energy storage materials and manufacturing. NREL''s on-site

Get Price

6 FAQs about [Lithium battery energy storage processing]

What is lithium-ion battery manufacturing?

As modern energy storage needs become more demanding, the manufacturing of lithium-ion batteries (LIBs) represents a sizable area of growth of the technology. Specifically, wet processing of electrodes has matured such that it is a commonly employed industrial technique.

How can lithium-ion battery manufacturing meet demand?

To meet this demand, battery manufacturing needs to be faster, cheaper, more dependable, less energy-intensive and less wasteful. A key part of lithium-ion battery manufacturing with significant room for improvement is the processing and fabrication of electrodes.

Are lithium-ion batteries the future of energy storage?

Provided by Argonne National Laboratory Numerous market analyses have shown that over the next five years, demand for lithium-ion batteries for everything from personal electric devices to grid-scale energy storage is expected to grow dramatically.

Can dry processing be used for lithium ion batteries?

In fact, for several years, multiple leading companies have been investigating the use of dry processing for battery cells. More information: Runming Tao et al, Advanced electrode processing for lithium-ion battery manufacturing, Nature Reviews Clean Technology (2025). DOI: 10.1038/s44359-024-00018-w Provided by Argonne National Laboratory

Why do we need lithium-ion batteries?

Numerous market analyses have shown that over the next five years, demand for lithium-ion batteries for everything from personal electric devices to grid-scale energy storage is expected to grow dramatically. To meet this demand, battery manufacturing needs to be faster, cheaper, more dependable, less energy-intensive and less wasteful.

Is high-throughput electrode processing necessary for lithium-ion battery market demand?

High-throughput electrode processing is needed to meet lithium-ion battery market demand. This Review discusses the benefits and drawbacks of advanced electrode processing methods, including aqueous, dry, radiation curing and 3D-printing processing methods.

More related information

-

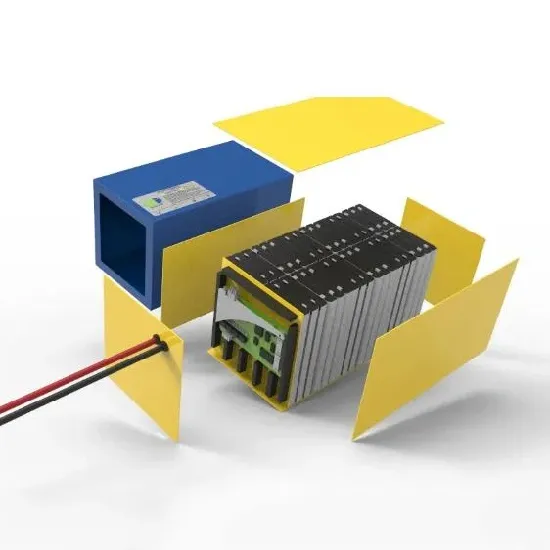

Malaysia energy storage lithium battery assembly and processing

Malaysia energy storage lithium battery assembly and processing

-

North Macedonia lithium battery energy storage equipment company

North Macedonia lithium battery energy storage equipment company

-

Comoros photovoltaic energy storage cabinet lithium battery

Comoros photovoltaic energy storage cabinet lithium battery

-

Commercial lithium battery energy storage system

Commercial lithium battery energy storage system

-

Lithium battery energy storage 100 kWh

Lithium battery energy storage 100 kWh

-

Timor-Leste lithium iron phosphate battery energy storage

Timor-Leste lithium iron phosphate battery energy storage

-

Lithium battery portable energy storage design price

Lithium battery portable energy storage design price

-

What are the energy storage lithium battery devices

What are the energy storage lithium battery devices

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.