Peak shaving and valley filling energy storage

In order to make the energy storage system achieve the expected peak-shaving and valley-filling effect, an energy-storage peak-shaving scheduling strategy considering the improvement goal

Get Price

Energy Storage System Configuration and Economic Evaluation

As an important part of the new power system, the energy storage system is beneficial for peak shaving and valley filling of electricity application and promotes the

Get Price

Peak and valley regulation of distribution

In order to give full play to the role of EVs in the peak shaving and valley filling for power grid, in this paper, we build a power grid peak load control model based on particle swarm

Get Price

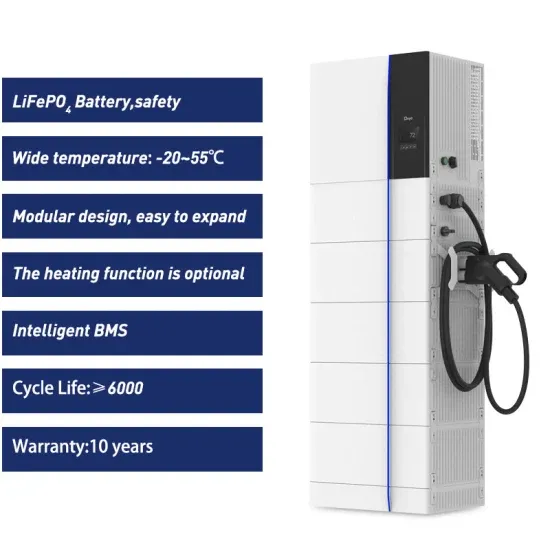

Peak shaving and valley filling

This system has built-in intelligent control equipment that can automatically store electricity during the valley period of low electricity prices and switch to the power supply mode during the peak

Get Price

How Can Industrial and Commercial Energy Storage Reduce

Among the most effective strategies are peak shaving, valley filling, and energy-saving cost reduction. This article explains how these techniques work and how C&I energy

Get Price

What Is Peak Shaving and Valley Filling?

3 days ago· Valley filling is the quieter sibling of peak shaving. It means using cheap, off-peak electricity when demand is low (typically at night), and storing it or shifting operations to those

Get Price

What is Peak Shaving and Valley Filling?

In today''s energy-driven world, effective management of electricity consumption is paramount. Two strategic approaches, peak shaving and valley filling, are at the forefront of

Get Price

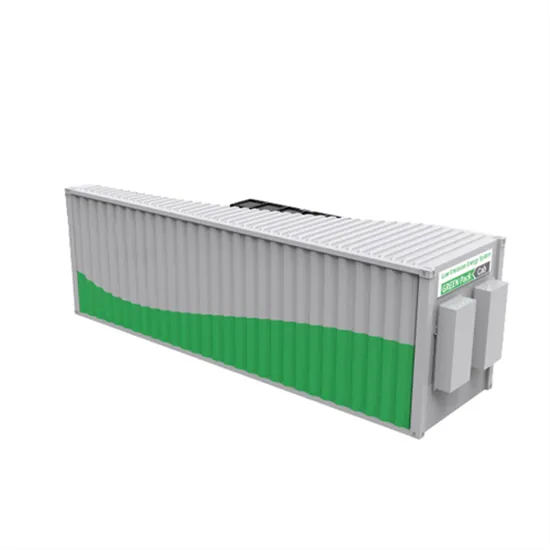

How Battery ESS Containers Help Industrial Users Maximize Peak Shaving

For industrial and commercial users, managing electricity costs is often a balancing act between operational efficiency and fluctuating energy demand. This is where the

Get Price

Improved peak shaving and valley filling using V2G

The analysis of the results proved the robustness of this solution in peak shaving during high demand periods and valley filling during off-peak hours by allowing a smoothing of the load

Get Price

Multi-objective optimization of capacity and technology selection

To support long-term energy storage capacity planning, this study proposes a non-linear multi-objective planning model for provincial energy storage capacity (ESC) and

Get Price

How Battery ESS Containers Help Industrial Users Maximize

For industrial and commercial users, managing electricity costs is often a balancing act between operational efficiency and fluctuating energy demand. This is where the

Get Price

Peak shaving and valley filling of power consumption profile in

In this paper, a mathematical model is implemented in MATLAB to peak-shave and valley-fill the power consumption profile of a university building by scheduling the

Get Price

PEAK SHAVING AND VALLEY FILLING ENERGY STORAGE

Energy storage to reduce peak loads and fill valley gaps The results of this study reveal that, with an optimally sized energy storage system, power-dense batteries reduce the peak power

Get Price

Peak shaving and valley filling energy storage project

This article will introduce Grevault to design industrial and commercial energy storage peak-shaving and valley-filling projects for customers.

Get Price

Impact Analysis of Energy Storage Participating in Peak Shaving

Result Through simulation calculations, the influence trend of energy storage participating in peak shaving and valley filling for the distribution network on network loss power and voltage loss is

Get Price

What Exactly Is The Commercial Energy Storage Model?

1. Owner self-investment model Description: Industrial and commercial enterprise owners invest in the construction of energy storage power stations and enjoy all the benefits.

Get Price

How Can Industrial and Commercial Energy Storage

Among the most effective strategies are peak shaving, valley filling, and energy-saving cost reduction. This article explains how these

Get Price

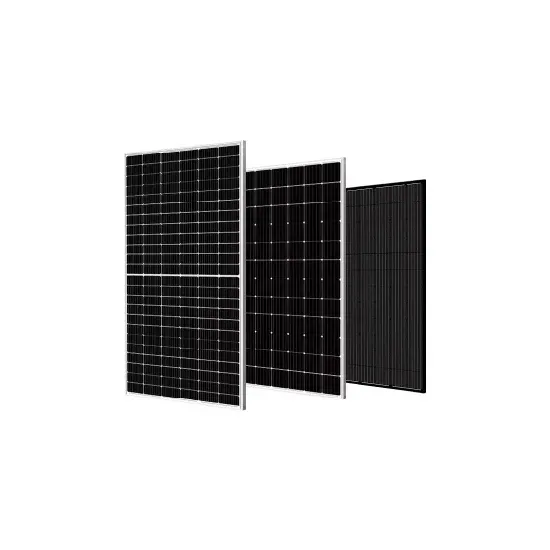

The energy storage system will be an important starting point for power

On the power supply side, the energy storage system will be an important tool for peak shaving, peak shaving and valley filling, and become a "cleaner power porter". For a period of time in

Get Price

What Is Peak Shaving and Valley Filling?

3 days ago· Valley filling is the quieter sibling of peak shaving. It means using cheap, off-peak electricity when demand is low (typically at night), and storing

Get Price

Peak and valley regulation of distribution network with

With the increasing number of electric vehicles (EVs), how to make full use of EVs to a peak shaving and valley filling effect on the electrical load,

Get Price

Multi-objective optimization model of energy storage participating

A multi-objective optimization model of energy storage participating in power grid peak shaving considering carbon footprint is established. The optimization model aims at the optimal PS-VF

Get Price

Peak Shaving and Valley Filling with Energy Storage Systems

Peak shaving and valley filling refer to energy management strategies that balance electricity supply and demand by storing energy during periods of low demand (valley) and releasing it

Get Price

HOW IS PEAK SHAVING AND VALLEY FILLING CALCULATED

Can nlmop reduce load peak-to-Valley difference after energy storage peak shaving? Minimizing the load peak-to-valley difference after energy storage peak shaving and valley-filling is an

Get Price

The Optimization Principle in the Era of Green

This involves two key actions: reducing electricity load during peak demand periods ("shaving peaks") and increasing consumption or storing

Get Price

Flexible Load Participation in Peaking Shaving and Valley

ABSTRACT Considering the widening of the peak-valley difference in the power grid and the difficulty of the existing fixed time-of-use electricity price mechanism in meeting the energy

Get Price

Energy Storage Peak Shaving and Valley Filling Project

This energy storage project, located in Qingyuan City, Guangdong Province, is designed to implement peak shaving and valley filling strategies for local industrial power consumption.

Get Price

The Optimization Principle in the Era of Green Energy:Peak Shaving

This involves two key actions: reducing electricity load during peak demand periods ("shaving peaks") and increasing consumption or storing energy during low-demand

Get Price

5 FAQs about [Enterprise peak shaving and valley filling power storage]

How can peak shaving and valley filling improve energy consumption?

The practices of peak shaving and valley filling not only address the economic aspects of energy consumption but also enhance the reliability and sustainability of energy infrastructures.

What is peak shaving & valley filling?

Manufacturing Plants: With peak shaving and valley filling, manufacturing facilities can optimize their energy use to coincide with the most beneficial times, both operationally and economically. The advancement of technology plays a pivotal role in enhancing the effectiveness of peak shaving and valley filling.

How much does peak shaving cost?

Peak shaving means trimming those spikes using tools like battery energy storage. Let’s say you have a plant running mostly at 200 kW, but twice a month you ramp up to 600 kW for an hour. Under demand-based billing (TOU or demand tariffs), that hour could cost you $0.30 to $0.50 per kilowatt. Now multiply that by 400 kW and 12 months

What is valley filling?

Valley filling, conversely, involves increasing energy consumption during periods of low demand. This method is employed to help utilities manage energy loads more evenly across the day. Valley filling can contribute to a more stable energy grid and prevent the wastage of energy resources.

Why is valley filling important?

Valley filling can contribute to a more stable energy grid and prevent the wastage of energy resources. Cost Efficiency: Utilizing energy during off-peak hours leverages lower electricity rates. Improved Equipment Utilization: Operating energy-intensive equipment during off-peak hours can enhance machinery lifespan and operational efficiency.

More related information

-

Japan s energy storage system peak shaving and valley filling solution

Japan s energy storage system peak shaving and valley filling solution

-

Gabon Energy Storage System Peak Shaving and Valley Filling Solution

Gabon Energy Storage System Peak Shaving and Valley Filling Solution

-

Commercial energy storage power station to reduce peak load and fill valley

Commercial energy storage power station to reduce peak load and fill valley

-

Panama Energy Storage Power Station Peak and Valley Electricity Prices

Panama Energy Storage Power Station Peak and Valley Electricity Prices

-

Africa Valley Power Storage System

Africa Valley Power Storage System

-

Iran Valley Power Storage Device

Iran Valley Power Storage Device

-

Kyrgyzstan Valley Power Energy Storage Device Manufacturer

Kyrgyzstan Valley Power Energy Storage Device Manufacturer

-

Pakistan Valley Power Energy Storage Device Manufacturer

Pakistan Valley Power Energy Storage Device Manufacturer

Commercial & Industrial Solar Storage Market Growth

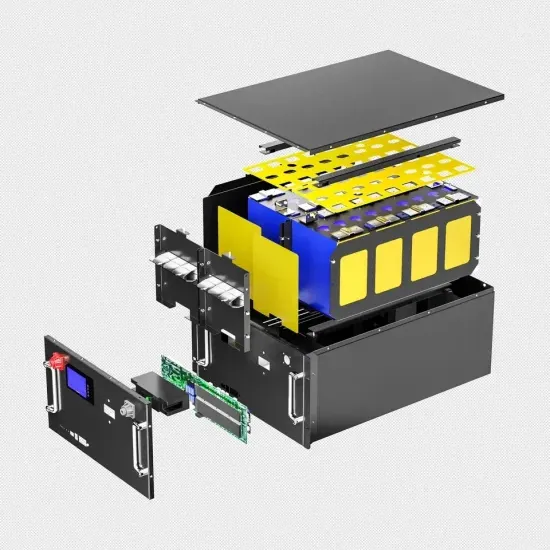

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.