Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Battery Materials Security and the Rise of Vertical Integration

Numerous examples and case studies that recognize the growing desire for vertical integration for players along the battery value chain can be found in the report.

Get Price

Floor-Standing Battery Storage Systems | XIHO Top Lithium Ion Battery

Shenzhen lithium battery supplier Xiho Power went to Thailand to participate in the ASEW exchange energy storage development trend, focusing on high-end customized lithium battery

Get Price

Custom Lithium Battery Pack Manufacturing

In this comprehensive technical guide, I''ll share an in-depth look at our end-to-end custom lithium battery pack manufacturing process.

Get Price

Battery Pack Development Timeline

Our battery pack development timeline covers the scope of a battery project and the time between developing prototypes and finally end product production.

Get Price

Advanced lithium-ion battery process manufacturing equipment

Using space-saving machinery and cost-effective, scalable technologies that can adapt to new battery advancements is a practical solution.

Get Price

How Tesla Rethought Lithium Ion Battery Cells

The Gigafactory is their new battery production plant currently under construction. This enormous facility is projected to build 50 gigawatt

Get Price

Why Is Vertical Integration Becoming a Trend in Rack Battery

Vertical integration in rack battery production enhances quality, reduces costs, accelerates innovation, and strengthens supply chain reliability. For manufacturers like

Get Price

Why Is Vertical Integration Becoming a Trend in Rack Battery Production?

Vertical integration in rack battery production enhances quality, reduces costs, accelerates innovation, and strengthens supply chain reliability. For manufacturers like

Get Price

Vertical Lithium Battery_Home Energy Storage Solar Battery

XIHO 51.2V 280Ah 15kWh Vertical LifePo4 Battery Pack: High-Density, Stackable Energy Storage for Home Solar Systems & Off-Grid Power. Fire-Proof Design, 10+ Year Lifespan, and 3x

Get Price

Stellantis and Zeta Energy Announce Agreement to

Upon completion of the project, the batteries are targeted to power Stellantis electric vehicles by 2030. Lithium-sulfur battery technology delivers

Get Price

Lilium Begins Battery Pack Production As

Lilium has begun producing battery packs for the first prototype Lilium Jet, with the first piloted flight of the electric vertical-takeoff-and-landing

Get Price

Solutions for your Lithium-Ion Battery production

Level-up your Lithium-ion battery production with proven and tailored solutions to enhance productivity and achieve the quality required by your EV market.

Get Price

Advanced Lithium-Ion Energy Storage Battery Manufacturing

Investments in some aspects of the domestic battery manufacturing supply chain have occurred, and imbalances within the domestic supply chain may continue. The U.S.

Get Price

Small-scale Lithium Battery PACK production line plant

These steps and equipment form the core of the lithium battery PACK production line, ensuring efficiency and quality control from raw materials to the final product.

Get Price

13 Largest Battery Manufacturers In The World [2025]

Did you know? China is the undisputed leader in battery manufacturing, dominating the global production of essential battery materials

Get Price

Professional Solar Manufacturer Home Storage Vertical Lithium

Professional Solar Manufacturer Home Storage Vertical Lithium Ion 15kwh Battery Pack, Find Details and Price about 15kwh Battery Lithium Ion Battery from Professional Solar

Get Price

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Price

Lilium Begins Producing Battery Packs for Electric Jet

Lilium Begins Producing Battery Packs for Electric Jet Each electric vertical takeoff and landing (eVTOL) Lilium Jet will include 10 battery

Get Price

The process flow of vertical section of lithium ion battery pack

The assembly segment process is a key link in lithium-ion battery manufacturing, which mainly includes four steps: winding, assembly, cell baking and liquid injection packaging. This article

Get Price

The process flow of vertical section of lithium ion

The assembly segment process is a key link in lithium-ion battery manufacturing, which mainly includes four steps: winding, assembly, cell baking and liquid

Get Price

PRODUCTION PROCESS OF BATTERY MODULES AND

PRODUCTION PROCESS OF BATTERY MODULES AND BATTERY PACKS. Dr. Sarah Michaelis Division Manager VDMA Battery Production Sarah.Michaelis@vdma . VDMA The

Get Price

51.2V 48V 300Ah 15kWh Vertical LifePo4 Battery Pack | XIHO Lithium

Vertical lithium battery pack is an efficient and compact energy storage solution. It adopts a unique vertical structure design, optimizing space utilization and facilitating integration into

Get Price

How Tesla Rethought Lithium Ion Battery Cells Through Modular

The Gigafactory is their new battery production plant currently under construction. This enormous facility is projected to build 50 gigawatt-hours per year by 2018 and will

Get Price

6 FAQs about [Vertical lithium battery pack production]

What is the production process of lithium-ion battery cells?

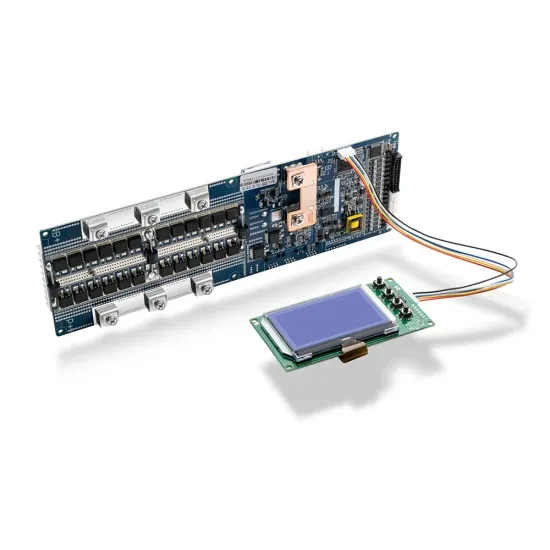

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

How can lithium-ion cell technology improve a custom pack design?

Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities. Concurrent electrical and mechanical engineering is needed to optimize the custom pack design within constraints.

More related information

-

High-power lithium battery pack production

High-power lithium battery pack production

-

Lithium battery pack production in Western Europe

Lithium battery pack production in Western Europe

-

Pack lithium battery production equipment

Pack lithium battery production equipment

-

Battery cabinet lithium battery pack warranty

Battery cabinet lithium battery pack warranty

-

Lithium battery pack maximum output current

Lithium battery pack maximum output current

-

Niue large capacity lithium battery pack

Niue large capacity lithium battery pack

-

Balancing the lithium battery pack

Balancing the lithium battery pack

-

Slovakia high-performance lithium battery pack

Slovakia high-performance lithium battery pack

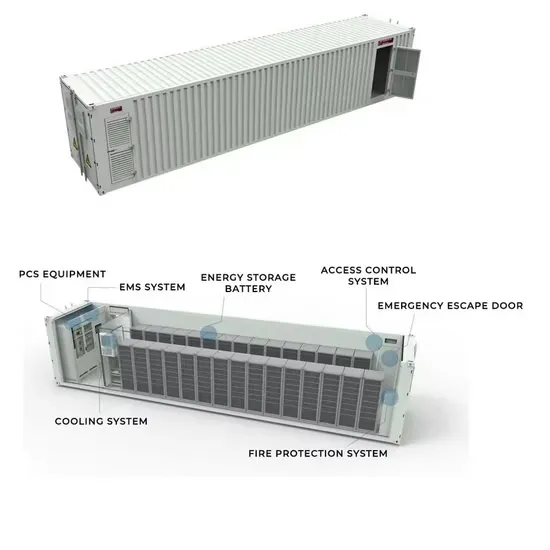

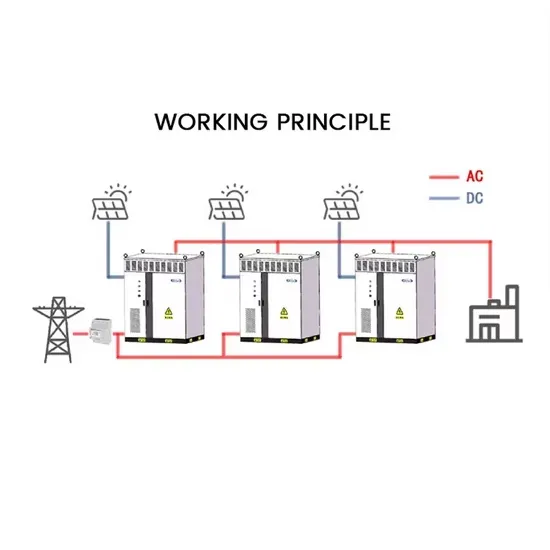

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

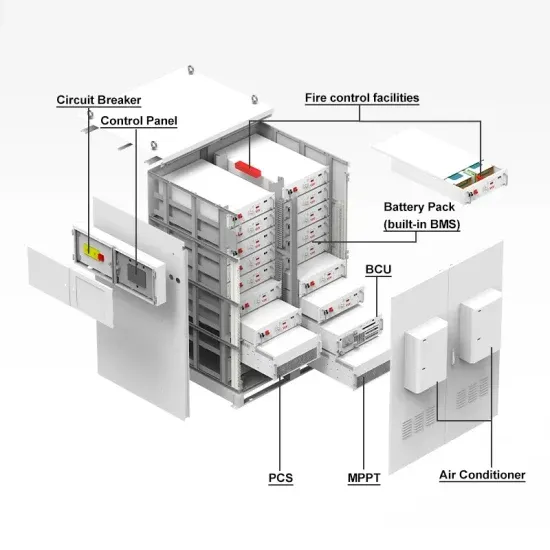

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.