Flat-Plate Collector

A flat plate collector (FPC) is defined as a device used to harvest solar energy and produce thermal heat, consisting of a transparent cover, a dark absorber plate that converts solar

Get Price

Schematic diagram of solar storage container (flat-plate collector

Schematic diagram of solar storage container (flat-plate collector). The system urea–sodium acetate trihydrate has been mentioned in the literature as an energy storage system. Due to...

Get Price

Experimental analysis of a flat plate solar collector with

With the purpose to determine the performance of a device on a lab scale, but with commercial features, a flat plate solar collector with phase change material (PCM) containers under the

Get Price

500kW/1.075MWh BESS 20ft Container Energy Storage

The whole is frame structure, the bottom is 5mm steel plate, the side plate adopts high strength container special plate, the wave height 36 mm; roof adopts tensile reinforcement roof, and the

Get Price

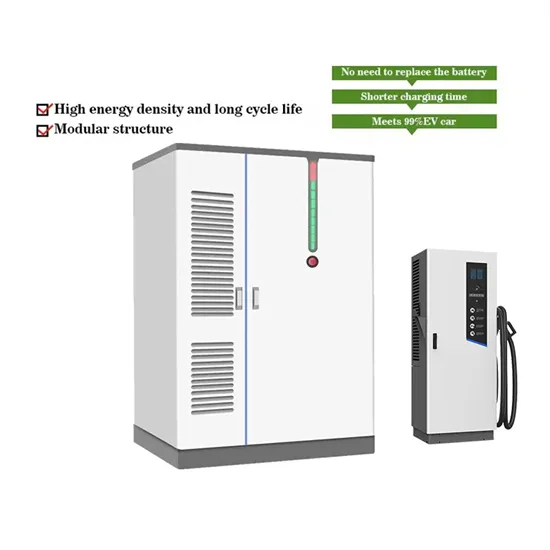

Energy storage container, BESS container

What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard containers to build

Get Price

A review of solar collectors and thermal energy storage in solar

Thermal applications are drawing increasing attention in the solar energy research field, due to their high performance in energy storage density and energy conversion

Get Price

<4D6963726F736F667420576F7264202D20C7E1E3CDC7D

3.1.1 Flat-Plate Collectors (FPCs) A typical flat-plate solar collector is shown in Figure 3.1. When solar radiation passes through a transparent cover and impinges on the blackened absorber

Get Price

Numerical simulation of phase change heat transfer of a solar flat

The technical feasibility of an innovative solar collector is studied in this paper. A phase change material (paraffin) is used in the solar collector to store solar energy. This type

Get Price

Collector Plate

A collector plate is defined as a component used in solar collectors that features a black finish on one side to maximize sunlight absorption while minimizing heat re-radiation, with efficient

Get Price

Schematic diagram of solar storage container (flat

Schematic diagram of solar storage container (flat-plate collector). The system urea–sodium acetate trihydrate has been mentioned in the literature as an

Get Price

Decoding Energy Storage Container Nameplates: Your Guide to

Ever wondered why engineers obsess over that metal plate riveted to your energy storage container? Well, it''s not just decoration – that nameplate holds the key to operational safety,

Get Price

Investigation of an Innovative Flat-Plate Integrated Collector-Storage

Request PDF | On Mar 1, 2025, Maria K. Koukou and others published Investigation of an Innovative Flat-Plate Integrated Collector-Storage Solar Water Heater with Latent Heat

Get Price

Container Energy Storage Systems

Our Container Energy Storage Systems offer wide operating temperature performance and high-efficiency power conversion. The integrated ECO controller enables intuitive monitoring, while

Get Price

US10636576B2

This disclosure provides collector plates for an energy storage device, energy storage devices with a collector plate, and methods for manufacturing the same. In one

Get Price

US Patent for Collector plate for energy storage device and

Conventional energy storage devices often include one or more conductive collector plates, each of which acts as an intermediary structure to provide electrical communication between an

Get Price

Exergy Analysis Of a Flat Plate Solar Collector With Latent Heat

Abstract and Figures An exergy analysis has been performed to determine the potential for useful work in a latent heat storage system with phase change material (PCM) for

Get Price

Analysis of a Flat-plate Solar Collector

Flat-plate collectors are the most common solar collector for solar water-heating systems in homes and solar space heating. A typical flat-plate collector is an insulated metal box with a

Get Price

Experimental Investigation of the Solar Latent Heat Thermal Energy

Methodology of Solar Latent Heat Thermal Energy Storage A structured approach for investigating the thermal performance of the energy storage system. Data Collection Charging

Get Price

Numerical simulation on phase change heat transfer of solar flat-plate

Download Citation | Numerical simulation on phase change heat transfer of solar flat-plate collector with energy storage | The technical feasibility of an innovative solar collector

Get Price

PPT-3

The document discusses solar energy collectors and solar energy storage. It describes different types of solar collectors including flat plate, evacuated tube, concentrating, focusing and non

Get Price

US20070231699A1

In one embodiment, an energy storage device comprises a container containing a first electrode generating a positive charge, a second electrode generating a negative charge, and an...

Get Price

Collector Plate

The absorber plate stores the solar energy that is transmitted through the collector cover. This stored energy can be used to heat the air when there is no sunlight.

Get Price

(PDF) ANALYSIS OF A FLAT PLATE SOLAR COLLECTOR

In the solar-energy industry great emphasis has been placed on the development of "active" solar energy systems which involve the integration of several subsystems: solar energy collectors,

Get Price

PPT-3

The document discusses solar energy collectors and solar energy storage. It describes different types of solar collectors including flat plate, evacuated

Get Price

What are the energy storage equipment plates?

Energy storage equipment plates represent an indispensable component of contemporary energy systems. Their ability to store, manage,

Get Price

(PDF) Design Analysis and Material Selection of Flat

Flat plate solar energy collectors are one of the oldest and most successful applications of solar energy utilization. They are usually

Get Price

What are the energy storage equipment plates? | NenPower

Energy storage equipment plates represent an indispensable component of contemporary energy systems. Their ability to store, manage, and optimize electrical energy is

Get Price

6 FAQs about [Energy Storage Container Collector Plate]

What is an example of a solar collector plate?

Example 7.1. A very long solar collector plate is to collect energy at a temperature of T1 = 350 K. To improve its performance for off-normal solar incidence, a surface, which is highly reflective at short wavelengths, is placed next to the collector as shown in Fig. 7-1.

How does a solar flat plate collector work?

The warmed fluid carries the heat either directly to the hot water or space conditioning equipment or to a storage subsystem from which can be drawn for use at night and on cloudy days. A precise and detailed analysis of a solar flat plate collector is quite complicated because of the many factors involved.

What is a collector plate?

In its simplest form the collector may be an ordinary central heating radiator panel. The materials most frequently used for collector plates, in decreasing order of cost and thermal conductivity, are copper, aluminium and steel. If the entire collector is swept by the heat transfer fluid, the conductivity of the material becomes unimportant.

What is a collector / absorber plate?

The collector or absorber plate is usually the most complex and expensive component of the collector, the remaining parts being freely available in the trade and in mass production for other purposes. This discussion concerns the liquid-heating type only, which may either be of the Tellier (double sheet) type or of the sheet and tube type.

What is a flat-plate collector?

A typical flat-plate collector is an insulated metal box with a glass or plastic cover (called the glazing) and a dark-colored absorber plate. These collectors heat liquid or air at temperatures less than 80°C. Flat-plate collectors are used for residential water heating and hydronic space-heating installations.

How do you find the maximum useful energy gain in a solar collector?

The maximum possible useful energy gain in a solar collector occurs when the whole collector is at the inlet fluid temperature. The actual useful energy gain (Qu), is found by multiplying the collector heat removal factor (FR) by the maximum possible useful energy gain. This allows the rewriting of equation (4):

More related information

-

Working principle of the collector plate of energy storage container

Working principle of the collector plate of energy storage container

-

Burundi northwest energy storage container

Burundi northwest energy storage container

-

Lead-acid battery energy storage container sales

Lead-acid battery energy storage container sales

-

Price of energy storage battery container

Price of energy storage battery container

-

Swaziland Huijue container energy storage system

Swaziland Huijue container energy storage system

-

Household side energy storage container system

Household side energy storage container system

-

China Solar Energy Storage Container Prices

China Solar Energy Storage Container Prices

-

5 MWh Energy Storage Container System

5 MWh Energy Storage Container System

Commercial & Industrial Solar Storage Market Growth

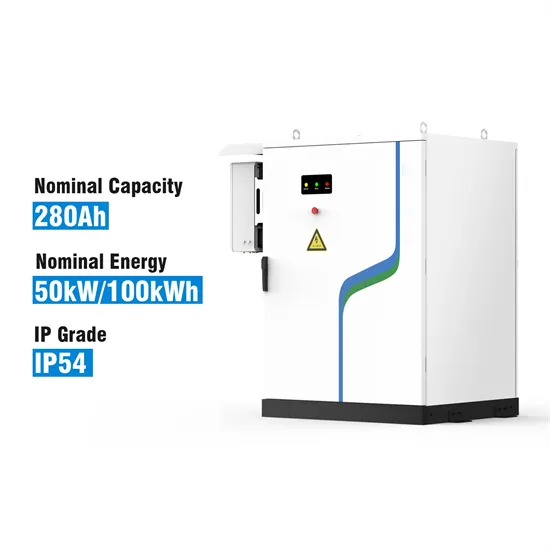

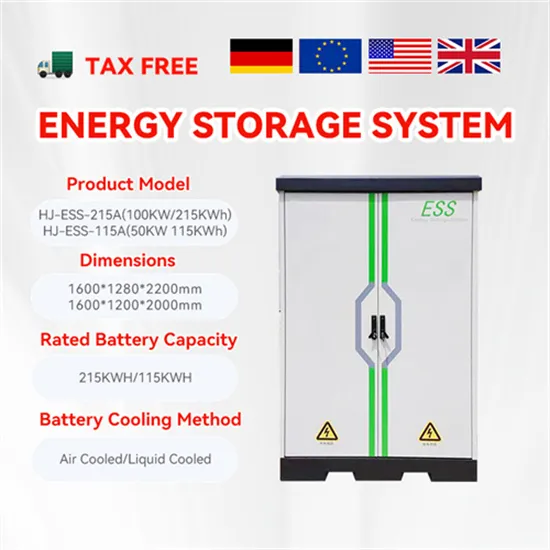

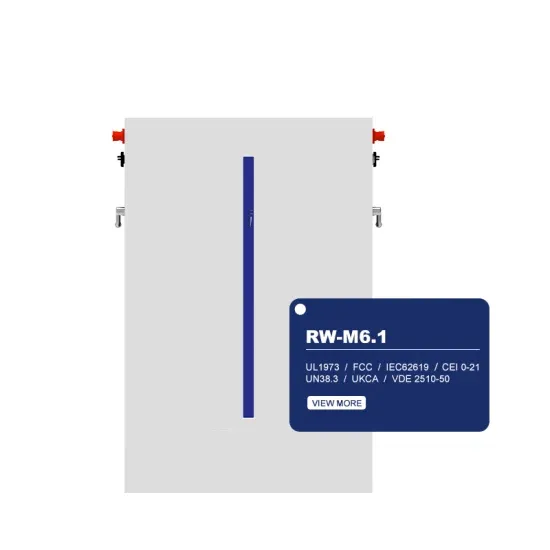

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.