Battery Remanufacturing | Battery Regulation Guidance

Achieve Battery Compliance At Every Stage With UL Solutions Regulatory Support. UL Solutions Provides Innovative Solutions For A Safer, More Secure And Sustainable World.

Get Price

lithium-ion battery production lines

Our product portfolio covers module and pack assembly for lithium-ion or sodium-ion batteries. Check our lithium-ion battery production lines.

Get Price

How to safely pack and ship batteries

Regulations differ depending upon what type of lithium battery you are shipping (lithium ion or lithium metal) and whether you are shipping batteries packed with equipment or batteries

Get Price

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Price

Essential Equipment for Lithium Battery Module Production Line

The production of lithium battery modules requires a range of specialized equipment to ensure efficiency and quality. Understanding the essential equipment for a

Get Price

Ultimate Guide to Equipment for Lithium Battery Assembly: Types

Lithium battery assembly equipment is the cornerstone of modern battery manufacturing, enabling the production of high-performance and reliable batteries used in

Get Price

Lithium-Ion Battery Packs | Vanguard® Commercial

Scalable. Serviceable. Sustainable. Vanguard ® Commercial Lithium-Ion Battery Packs provide unmatched power, reduced maintenance and lower total cost of

Get Price

How To Ship Batteries | UPS

The training course will guide attendees through general lithium battery requirements as well, as providing step-by-step procedures on how to classify, package and ship lithium batteries

Get Price

Custom Battery Packs & Assemblies | Power Solutions

For over 57 years, Custom Power has designed, developed, and manufactured high-quality, reliable, custom battery packs. We provide battery pack assemblies in all chemistries,

Get Price

What equipment is needed to produce lithium battery packs and lithium

What equipment is needed for the production of lithium battery packs and lithium battery packs? The production and processing equipment of lithium battery packs and lithium battery packs

Get Price

Lithium Battery PACK Production Line Processes and Equipment

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Get Price

Essential Equipment Required to Assemble Lithium Battery Packs

Looking to build lithium battery packs? Discover the must-have tools, industry insights, and expert tips to streamline your assembly process.

Get Price

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Get Price

The Manufacturing Process of Lithium Batteries Explained

The lithium battery manufacturing industry is dominated by countries like China, Japan, and South Korea, which are major manufacturers and suppliers of equipment for lithium-ion cell production.

Get Price

How to Choose Lithium Battery Solutions: Expert Guide for

The type of lithium battery required for industrial applications is determined by the specific requirements of the equipment being powered: device voltage,

Get Price

What equipment is needed to install lithium battery for energy

To install lithium batteries for energy storage, a variety of equipment is essential. 1. Lithium batteries, crucial for energy retention and efficiency, 2. Battery management system

Get Price

Ultimate Guide to Equipment for Lithium Battery Assembly: Types

Each stage requires specialized equipment to handle tasks like coating, cutting, stacking, welding, and testing. The quality and performance of the final battery product heavily

Get Price

Lithium-ion Battery Safety

Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to many devices we

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

For example, if used in an electric vehicle, the battery pack must fit the vehicle''s space precisely. At the same time, using a high-strength structural design can resist impact

Get Price

Lithium Battery Regulations and Standards in the US:

Guide to UL standards, CPSIA, Amazon requirements, lab testing, and certification for lithium battery products to the US.

Get Price

What equipment is needed to produce lithium battery packs and

What equipment is needed for the production of lithium battery packs and lithium battery packs? The production and processing equipment of lithium battery packs and lithium battery packs

Get Price

Introduction to Production Equipment and Testing Methods for Lithium

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

Introduction to Production Equipment and Testing Methods for

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get Price

Optimal Lithium Battery Charging: A Definitive Guide

Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get Price

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get Price

6 FAQs about [Equipment required for lithium battery pack]

What is a lithium battery pack?

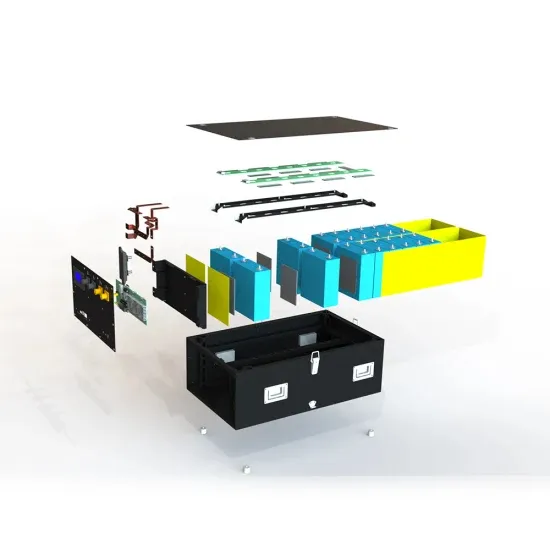

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How does a lithium battery pack work?

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment. Quality Control: Every step, from mixing to testing, demands extreme precision. Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

Why do custom lithium-ion batteries need a lifecycle mindset?

Once produced, properly supporting packs throughout service life is paramount: This lifecycle mindset maximizes the ROI of custom lithium-ion battery investments. Working with lithium-ion cells and batteries necessitates rigorous safety protocols given flammability risks if improperly handled.

More related information

-

West Africa pack lithium battery equipment

West Africa pack lithium battery equipment

-

Lithium battery pack assembly equipment

Lithium battery pack assembly equipment

-

Fengyu rechargeable lithium battery pack

Fengyu rechargeable lithium battery pack

-

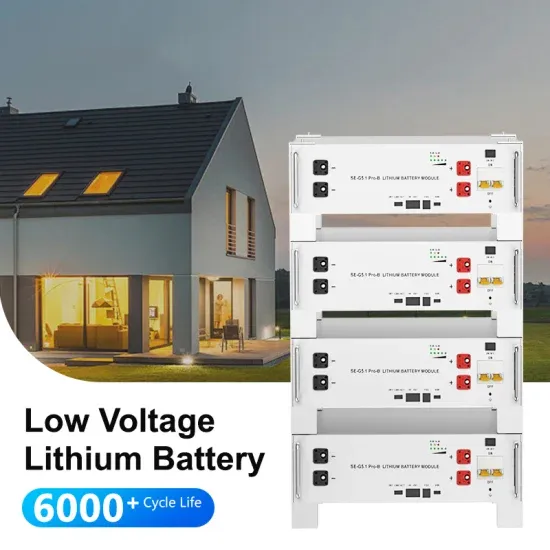

Armenia lithium iron phosphate battery pack for sale

Armenia lithium iron phosphate battery pack for sale

-

Cape Verde lithium battery pack

Cape Verde lithium battery pack

-

48v lithium battery pack wall mounted

48v lithium battery pack wall mounted

-

48v lithium battery pack useful 15 sets in series

48v lithium battery pack useful 15 sets in series

-

Total positive and negative temperature of lithium battery pack

Total positive and negative temperature of lithium battery pack

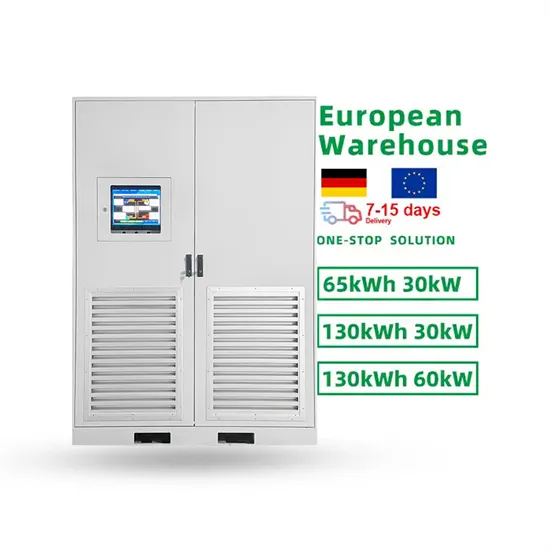

Commercial & Industrial Solar Storage Market Growth

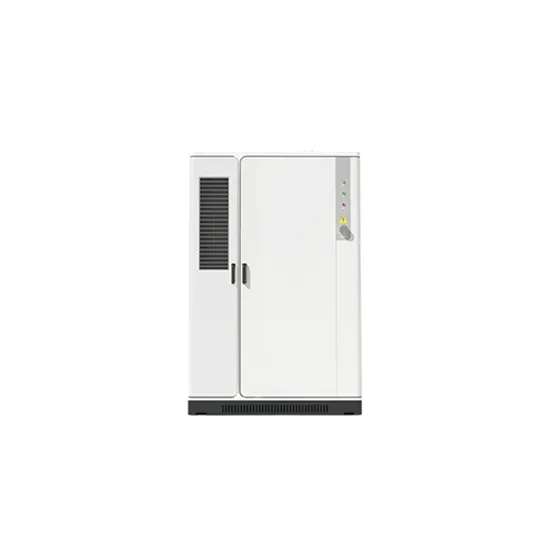

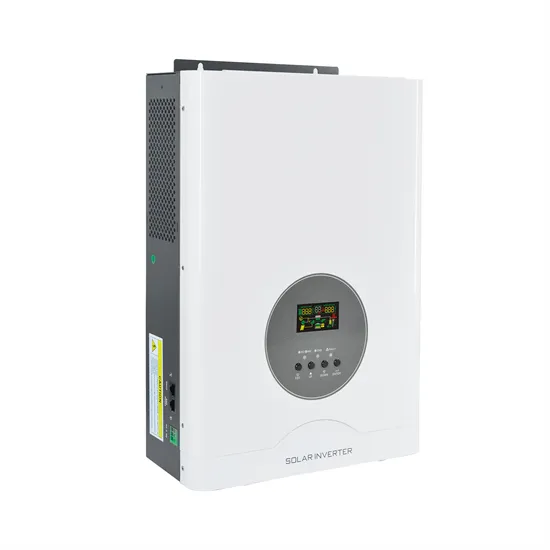

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.