A Transformation Milestone

These layers are stacked on top of each other, assembled into battery packs and then tested thoroughly. The construction of the first production facilities has already begun. Once work is

Get Price

Lithium Battery Production Process and Key Equipment

Lithium battery packs are the heart of the new energy revolution, and their assembly is a critical process. This article dives into the key stations and

Get Price

Battery Storage Cabinets: The Backbone of Safe and Efficient

This comprehensive guide delves into the intricacies of battery storage cabinets, exploring their design, functionality, and the technological advancements that make them

Get Price

The Manufacturing Process of Lithium Batteries

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage

Get Price

A Guide to Battery Energy Storage System

In more detail, let''s look at the critical components of a battery energy storage system (BESS). Battery System The battery is a crucial component within the

Get Price

Can Battery Charging Stations Cause a False Positive Reading

Yes, battery charging stations can cause false positives on CO detectors. This occurs due to chemical interactions or sensor cross-sensitivity. Experts confirm these incidents

Get Price

How EV Batteries Are Made: The Cell Manufacturing Process

The final steps involve assembling the battery cells into modules and the EV battery pack. After this, the battery pack is assembled into a protective housing in the vehicle

Get Price

Lithium Battery Production Process and Key Equipment

Lithium battery packs are the heart of the new energy revolution, and their assembly is a critical process. This article dives into the key stations and equipment that make up a lithium battery

Get Price

Lithium-ion Battery Module and Pack Production Line

First, the battery cells are put into the production line manually, then the production line equipment automatically scans the battery cells, and

Get Price

The Manufacturing Process of Lithium Batteries Explained

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage comprises specific sub-processes

Get Price

Battery cells to high-voltage battery cabinets! Factory live

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact

Get Price

Production Process of Battery Modules and Battery

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Get Price

Full Explanation of Lithium Battery Production Process

These layers are stacked on top of each other, assembled into battery packs and then tested thoroughly. The construction of the first production facilities has already begun. Once work is

Get Price

How EV Batteries Are Made: The Cell Manufacturing

The final steps involve assembling the battery cells into modules and the EV battery pack. After this, the battery pack is assembled into a

Get Price

What Is the Battery Capacity of Tesla Model Y

Supercharging speeds depend on multiple factors: battery state of charge (slowest above 80%), temperature (optimal at 50-60°C), station congestion (shared power cabinets),

Get Price

Full Explanation of Lithium Battery Production Process

The intricate production process involves more than 50 steps, from electrode sheet manufacturing to cell synthesis and final packaging. This article explores these stages in

Get Price

Lithium-ion Battery Module and Pack Production Line Process Flow

First, the battery cells are put into the production line manually, then the production line equipment automatically scans the battery cells, and at the same time carries out the

Get Price

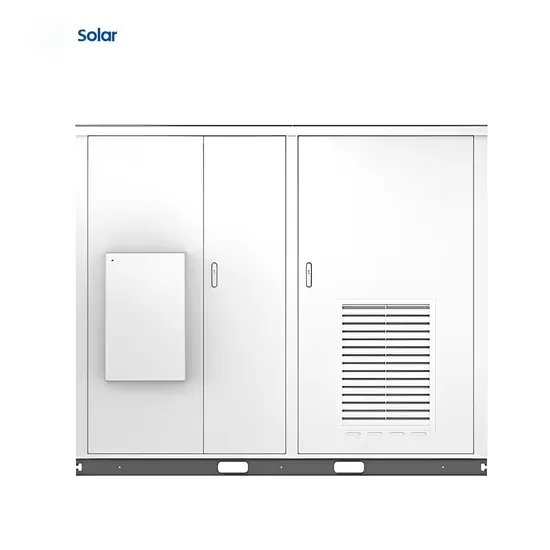

Carbfix battery casing: | C&I Energy Storage System

But what makes these power banks tick? Let''s dissect the Bill of Materials (BOM) that transforms lithium dreams into tangible electricity. [2023-03-26 05:15] portable energy storage systems

Get Price

Battery Storage Cabinets: The Backbone of Safe and

This comprehensive guide delves into the intricacies of battery storage cabinets, exploring their design, functionality, and the technological

Get Price

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get Price

Li-ion cell manufacturing: A look at processes and equipment

The formation process describes the first charging and discharging processes of the battery cell after the electrolyte is injected into it. The cells are placed in information racks

Get Price

Battery cabinets are process materials

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which can be placed with various types

Get Price

battery cabinet,battery storage cabinet,battery bank

EverExceed designs customized battery cabinets / racks for individual batteries. The cabinet or racking system can be specified to accomodate any battery

Get Price

6 FAQs about [Battery cells are processed into battery station cabinets]

What is battery cell manufacturing process?

The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs. It consists of three major stages: electrode manufacturing, cell assembly, and cell finishing. Each step plays a crucial role in determining the battery’s performance and reliability. 1.

How does a battery production line work?

First, the battery cells are put into the production line manually, then the production line equipment automatically scans the battery cells, and at the same time carries out the internal resistance and voltage test, in order to screen out the battery cells with qualified quality.

How are lithium ion batteries made?

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage comprises specific sub-processes to ensure the quality and functionality of the final product. The first stage, electrode manufacturing, is crucial in determining the performance of the battery.

How are battery modules produced?

The modules produced are inserted into battery layers on the production line. These layers are stacked on top of each other, assembled into battery packs and then tested thoroughly. The construction of the first production facilities has already begun.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is battery module assembly process?

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage enhances efficiency, safety, and performance by integrating electrical connections, thermal management systems, and safety features.

More related information

-

Where can I get custom-made lithium battery station cabinets in Mauritius

Where can I get custom-made lithium battery station cabinets in Mauritius

-

What brands of lithium battery station cabinets are good

What brands of lithium battery station cabinets are good

-

Enterprises that acquire a large number of lithium battery station cabinets

Enterprises that acquire a large number of lithium battery station cabinets

-

Battery Cabinets and Cells

Battery Cabinets and Cells

-

Requirements for new energy battery station cabinets

Requirements for new energy battery station cabinets

-

Battery cabinet frame base station power generation

Battery cabinet frame base station power generation

-

Lithium battery station cabinet OEM

Lithium battery station cabinet OEM

-

Benin Mobile Base Station Battery Procurement

Benin Mobile Base Station Battery Procurement

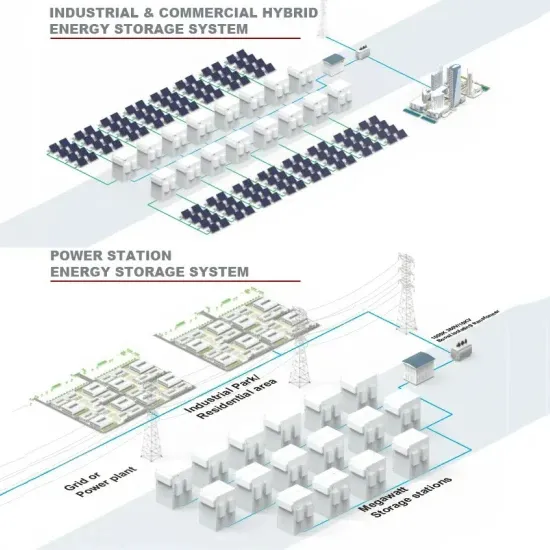

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.