How Liquid Cooling is Transforming Battery Energy

The above diagram illustrates how liquid cooling works in battery energy storage systems. The coolant circulates through cold plates attached to battery

Get Price

Battery Cabinet

The battery cabinet is made of cold rolled steel or galvanization plates of high mechanical performance and bearing capacity. The compact structure with

Get Price

Designing a Battery Cooling Plate: Strategies & Innovations

Battery cooling plates manage cell temperature to ensure optimal battery performance, longevity, and safety. They are typically made from materials with high thermal conductivity, such as

Get Price

Liquid Cooling Cold Plate: The Ultimate Guide

This article provides a comprehensive guide to liquid cooling cold plate, its types, applications, advantages, and disadvantages. Learn about liquid cooling cold plate in this

Get Price

What is a Battery Cooling Plate? Composition and Requirements

Excess heat generated by the battery is transferred through contact with the surface of the plate-shaped aluminum device, which is then taken away by the coolant flowing

Get Price

What is an Electric Vehicle Battery Cold Plate

Electric vehicle (EV) battery cold plates are essential components designed to manage the thermal conditions of EV batteries. These plates play a crucial role in maintaining optimal

Get Price

Cold Plate Cooling: The Ultimate Guide

Looking for reliable information on cold plate cooling? Our guide covers everything you need to know about this liquid cooling technique for electronic devices and applications.

Get Price

(PDF) A novel cold plate design for liquid-based battery thermal

A novel cold plate design for liquid-based battery thermal management through multi objective topology optimization October 2024

Get Price

Battery Cold Plate

Built with lightweight aluminum, the battery cold plate stabilizes battery cell temperature and provides optimal temperature uniformity. Featuring counterflow and double-side cell loading

Get Price

Types of Cold Plates Used In The New Energy Sector

If you''re wondering whether cold plates improve EV performance, here''s what you should know. They keep cells within 20–40 °C, which extends

Get Price

What is a Battery Cold Plate?

Battery cold plates are the core of a battery thermal management system. They are designed to efficiently remove heat from the battery cells through physical contact.

Get Price

Battery Cold Plate

Built with lightweight aluminum, the battery cold plate stabilizes battery cell temperature and provides optimal temperature uniformity. Featuring

Get Price

Analysis of Heat Transfer Characteristics and Optimization of Cold

To ensure a suitable temperature range and temperature difference performance for on-board power battery, the heat transfer characteristics analysis and structural parameter optimization

Get Price

Electric Vehicle Liquid Cold Plate Case Study

When creating a new series of batteries for electric vehicles (EVs), a leading battery producer approached Boyd to design new liquid cold plates for the battery packs. The new battery

Get Price

Battery Cold Plate | Direct Cooling Plate for EV Car Batteries

A direct cooling cold plate is a thermal management component that allows direct contact between the refrigerant and the battery cells, enabling rapid heat dissipation.

Get Price

What Are Cold Plates

What Are Cold Plates and Their Basic Function Cold plates are special heat exchangers that remove heat from electronic parts well. At Trumonytechs, we offer battery pack thermal

Get Price

Types of Cold Plates Used In The New Energy Sector

If you''re wondering whether cold plates improve EV performance, here''s what you should know. They keep cells within 20–40 °C, which extends battery life and prevents thermal

Get Price

Industrial Battery Cabinet Racks in UAE in Effective Range

The battery cabinets are powder coated finish powder coated & oven dried for great finish and corrosion resistance. The box is designed for cables or conduits entry through a gland plate in

Get Price

How Liquid Cold Plates and Battery Cooling Pumps Improve EV

When the battery cells produce heat, the cold plate absorbs that heat, and the coolant carries that heat out of the system. A friend of mine who is a thermal engineer told me

Get Price

What is a Battery Cooling Plate? Composition and

Excess heat generated by the battery is transferred through contact with the surface of the plate-shaped aluminum device, which is then

Get Price

What Are Cold Plates

The main parts are the metal plate, the tubes, inlet and outlet ports, and mounting features. Cold plates work by moving heat from parts to a cooling liquid. They use conductive and convective

Get Price

What is an Electric Vehicle Battery Cold Plate

Electric vehicle (EV) battery cold plates are essential components designed to manage the thermal conditions of EV batteries. These plates play a crucial

Get Price

Effect of inlet and outlet positions on heat

This study applied topology optimization methods to design a cold plate with topology channels for a square battery. With maximum heat transfer as the optimization

Get Price

PERFORMANCE INVESTIGATION OF THERMAL

Energy storage like batteries is essential for stabilizing the erratic electricity supply. High temperatures when the power is charged and discharged will pro-duce high temperatures

Get Price

Key Features to Look for in EV Battery Cell Cold Plates – XD

A critical component in maintaining the optimal performance of EV batteries is the cooling system, particularly the cold plates that manage thermal regulation. Choosing the right EV battery cell

Get Price

How Liquid Cold Plates and Battery Cooling Pumps Improve EV

Liquid cold plates are a flat metal surface that is in direct contact with the EV battery cells. They contain narrow channels through which coolant fluid circulates. When the battery

Get Price

Battery Cabinets vs. Battery Racks

On battery cabinets, the disconnect switch should be mounted in the door to allow the battery to be disconnected from the UPS before the door

Get Price

More related information

-

What are the battery energy storage cabinet manufacturers in Belize

What are the battery energy storage cabinet manufacturers in Belize

-

What is the sufficient capacity of a new energy battery cabinet

What is the sufficient capacity of a new energy battery cabinet

-

What is the formula for calculating battery cabinet power

What is the formula for calculating battery cabinet power

-

What are the battery cabinet manufacturers

What are the battery cabinet manufacturers

-

What is the full name of the site energy battery cabinet

What is the full name of the site energy battery cabinet

-

What type of technology is the battery cabinet base station power

What type of technology is the battery cabinet base station power

-

What to do if the battery in the energy storage cabinet becomes hot

What to do if the battery in the energy storage cabinet becomes hot

-

What are the requirements for battery cabinet installation

What are the requirements for battery cabinet installation

Commercial & Industrial Solar Storage Market Growth

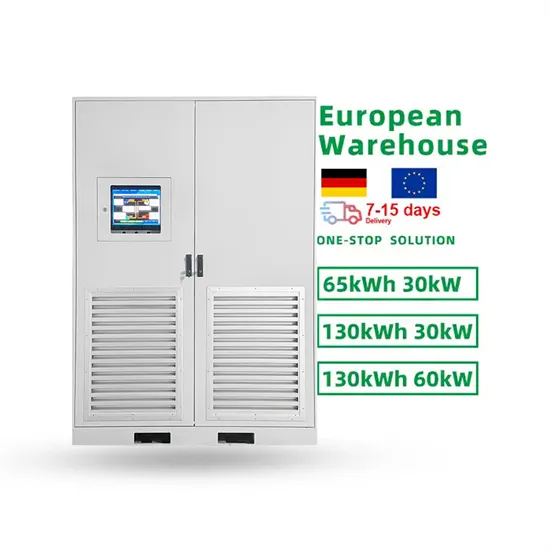

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.