Investigation of Ferrosilicon Produced with Si Recovered from

Although photovoltaics is among the most promising technologies for sustainable energy production [4, 5, 6], optimal waste management for end-of-life solar panels remains

Get Price

Crystal arrangement results in 1,000x more power

Combining ultra-thin layers of different materials can raise the photovoltaic effect of solar cells by a factor of 1,000, according to researchers

Get Price

Ferrosilicon Production from Silicon Wafer Breakage

Therefore, this study illustrates an alternative approach that combines Si recovered from broken c-Si PV panels and RM from the alkaline leaching of

Get Price

Silicon Solar Cell: Types, Uses, Advantages & Disadvantages

A silicon solar cell is a photovoltaic cell made of silicon semiconductor material. It is the most common type of solar cell available in the market. The silicon solar cells are

Get Price

Aluminium alloyed iron-silicide/silicon solar cells: A simple

This work demonstrates the fabrication of silicide/silicon based solar cell towards the development of low cost and environmental friendly photovoltaic technology.

Get Price

Comprehensive review of the material life cycle and sustainability

The primary objective of this literature review is to provide a detailed discussion on environmentally friendly extraction and refining methods of solar PV materials across three

Get Price

Investigation of Ferrosilicon Produced with Si Recovered from

For example, the Si extracted from the EOL PV panels is purified and is used to make the solar cells which are then incorporated into the PV panels [20, 21] ually silicon

Get Price

Ferro Silicon 75 For Semiconductor Industry

Description Ferrosilicon can be used to produce wafers, one of the key steps in the semiconductor manufacturing process. A wafer is a very thin piece of silicon, usually 200 mm or 300 mm in

Get Price

99.9999% Pure Si Silicon Granules Polysilicon Ingot for Solar Panels

High quality 99.9999% Pure Si Silicon Granules Polysilicon Ingot for Solar Panels from China, China''s leading product market Silicon Metal product, with strict quality control Silicon Metal

Get Price

Ferrosilicon

Ferrosilicon is a basis for manufacture of prealloys like magnesium ferrosilicon (MgFeSi), used for production of ductile iron. MgFeSi contains 3–42% magnesium and small amounts of rare

Get Price

An overview on ferroelectric photovoltaic materials

Harnessing solar energy as an alternative to compensate the depleting nonrenewable energy resources is a technological field with great potential. Silicon-based

Get Price

Better Solar Panels With Ferroelectric Material

By amplifying the photovoltaic effect in ferroelectric crystals, the new material has the potential to boost solar panel efficiency significantly. This advancement would make solar

Get Price

Crystalline-silicon based PV panel composition.

Using dynamics modelling, a comprehensive analysis of silicon flows applied in green energy technologies such as photovoltaic (PV) solar panels and lithium-ion batteries (LiBs) is provided.

Get Price

Silicon on Metalshub

What is silicon used for? Silicon is primarily used in the electronics industry (~40%), where it is essential for semiconductor manufacturing and integrated circuits. It is also used in the

Get Price

Ferrosilicon

Ferrosilicon is a basis for manufacture of prealloys like magnesium ferrosilicon (MgFeSi), used for production of ductile iron. MgFeSi contains 3–42%

Get Price

Greenhouse Gas Emissions from Silicon Production

PDF | On Jan 1, 2021, Gudrun Sævarsdottir and others published Greenhouse Gas Emissions from Silicon Production -Development of Carbon Footprint with

Get Price

High-Quality Quartz Lumps Supplier India | Moltech

Solar Panel Raw Materials for Efficient Energy Production We provide a comprehensive Solar Panel Raw Material List, including quartz and silica,

Get Price

Ferro Titanium for Solar Panels

Ferro Titanium is a key component in the production of solar panels, offering enhanced conductivity, corrosion resistance, light absorption, and cost-effective manufacturing. Its

Get Price

Better Solar Panels With Ferroelectric Material

By amplifying the photovoltaic effect in ferroelectric crystals, the new material has the potential to boost solar panel efficiency significantly. This

Get Price

What Are Solar Panels Made Of and How Are They

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel

Get Price

Crystal arrangement results in 1,000x more power from

Combining ultra-thin layers of different materials can raise the photovoltaic effect of solar cells by a factor of 1,000, according to researchers at Martin Luther University Halle

Get Price

Ferroalloys

Marubeni Tetsugen is a trading company specialized in metals, mainly in steel and ferroalloy.We handle recycled steel, which has a central importance of resolving environmental issues, as

Get Price

Solar Cells & Solar Panels

Shop solar panels and cells. Build your own solar panels using our selection of solar cells or find flexible or glass frame solar panels from 1W to 400 W.

Get Price

Making Ferroelectric Solar Cells Better

Researchers claim that using several very thin layers of ferroelectric crystals can lead to significantly better ferroelectric solar cell efficiency. But don''t pull the panels off your

Get Price

Crystalline-silicon based PV panel composition.

Using dynamics modelling, a comprehensive analysis of silicon flows applied in green energy technologies such as photovoltaic (PV) solar panels and lithium

Get Price

Making Ferroelectric Solar Cells Better

Researchers claim that using several very thin layers of ferroelectric crystals can lead to significantly better ferroelectric solar cell

Get Price

Production of Ferrosilicon Solar Panels

The manufacturing process of solar panels primarily involves silicon cell production, panel assembly, and quality assurance. Starting from silicon crystals, the process

Get Price

| Material Insights

Common applications of silicon include manufacturing solar panels from polysilicon, producing semiconductors or integrated circuits on chips made from pure silicon, and as silica sand and

Get Price

Ferrosilicon Production from Silicon Wafer Breakage and Red Mud

Therefore, this study illustrates an alternative approach that combines Si recovered from broken c-Si PV panels and RM from the alkaline leaching of bauxite to produce marketable

Get Price

6 FAQs about [Solar panel ferrosilicon]

What is ferroelectric PV?

The field of ferroelectric PV is evolving and not yet completely understood compared to the semiconductor-based PV technology. PV materials and devices, commonly known as solar cells, convert sunlight into electrical energy. Generation of electricity in a clean, quiet, and reliable way is one of the major attractions of PV technology.

What is ferrosilicon used for in arc welding?

In arc welding, ferrosilicon can be found in some electrode coatings. Ferrosilicon is a basis for manufacture of prealloys like magnesium ferrosilicon (MgFeSi), used for production of ductile iron. MgFeSi contains 3–42% magnesium and small amounts of rare-earth elements.

Can ferroelectric crystals make solar panels easier to produce?

Ferroelectric crystals differ from conventional silicon cells in that they do not require a p-n junction to create the PV effect. In other words, there is no need to create positively and negatively doped layers within the cell. The researchers said that change could make solar panels easier to produce.

What is ferrosilicon used for?

It can be used to make other ferroalloys. Ferrosilicon is also used for manufacture of silicon, corrosion-resistant and high-temperature-resistant ferrous silicon alloys, and silicon steel for electromotors and transformer cores. In the manufacture of cast iron, ferrosilicon is used for inoculation of the iron to accelerate graphitization.

Are ferroelectric solar panels better than conventional solar panels?

Researchers claim that using several very thin layers of ferroelectric crystals can lead to significantly better ferroelectric solar cell efficiency. But don’t pull the panels off your roof yet. Conventional cells are still much more efficient than ferroelectric devices — at least, for now.

Are silicon flows applied in green energy technologies?

Using dynamics modelling, a comprehensive analysis of silicon flows applied in green energy technologies such as photovoltaic (PV) solar panels and lithium-ion batteries (LiBs) is provided.

More related information

-

Solar panel voltage regulator and inverter

Solar panel voltage regulator and inverter

-

Solar photovoltaic panel per square meter

Solar photovoltaic panel per square meter

-

How many kilowatts can a solar panel output

How many kilowatts can a solar panel output

-

The most efficient solar panel

The most efficient solar panel

-

Slovakia invests in solar panel companies

Slovakia invests in solar panel companies

-

Can solar panel sun sheds be used for photovoltaics

Can solar panel sun sheds be used for photovoltaics

-

Which solar panel photovoltaic module manufacturer is best in Haiti

Which solar panel photovoltaic module manufacturer is best in Haiti

-

Communication base station solar panel production company

Communication base station solar panel production company

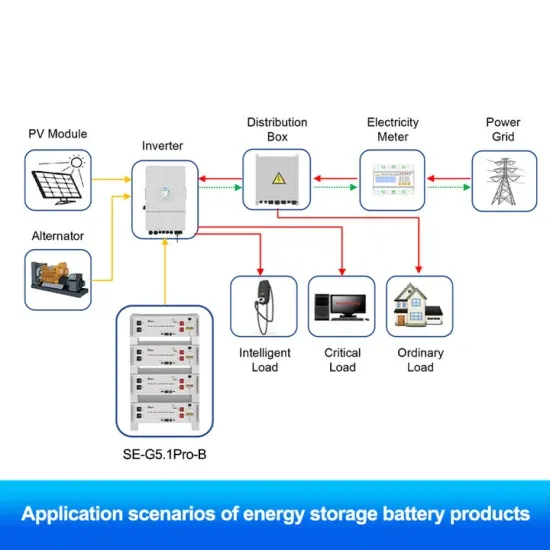

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.