Lithium Iron Phosphate (LFP)

Starting materials for LFP synthesis vary but are comprised of an iron source, lithium hydroxide or carbonate (an organic reducing agent), and a phosphate component. The iron raw material

Get Price

Industrial preparation method of lithium iron

What needs to be improved in the production process of the solid phase method of lithium iron phosphate is to increase production efficiency, reduce

Get Price

Industrial preparation method of lithium iron phosphate (LFP)

What needs to be improved in the production process of the solid phase method of lithium iron phosphate is to increase production efficiency, reduce preparation costs, and improve the

Get Price

Concerns about global phosphorus demand for lithium-iron-phosphate

Xu et al. 1 offer an analysis of future demand for key battery materials to meet global production scenarios for light electric vehicles (LEV). They conclude that by 2050, demands

Get Price

Slovenia Lithium Iron Phosphate (LiFePO4) Battery Market (2024

Slovenia Lithium Iron Phosphate (LiFePO4) Battery Market is expected to grow during 2023-2029

Get Price

Top Lithium Ferro Phosphate Battery Suppliers in Slovenia

Lithium Ferro Phosphate batteries are environmentally friendly and help to reduce the carbon footprint of the population. From Solar power storage to EVs, the Lithium Ferro battery market

Get Price

Analysis of global battery production: production locations and

The cathode is a central component of a lithium-ion battery cell and significantly influences its cost, energy density, i.e. relative storage capacity, and safety. Two materials

Get Price

Top 12 LiFePO4 Battery Manufacturers in the World

Top 12 LiFePO4 Battery Manufacturers in the World In the rapidly evolving energy storage market, lithium iron phosphate (LiFePO4) batteries have emerged as

Get Price

Production process of lithium iron phosphate

1. Lithium iron phosphate production process: Lithium iron phosphate is a multifunctional new lithium-ion battery system. Its safety, endurance and cycle life are much

Get Price

FIRST GIGAFACTORY IN SLOVENIA – TAB

BM-Rosendahl has been producing special machines for the assembly of automotive, motorcycle and industrial batteries for more than 50 years. The product range

Get Price

Exploring sustainable lithium iron phosphate cathodes for Li-ion

Understanding the supply chain from mine to battery-grade precursors is critical for ensuring sustainable and scalable production. This review provides a comprehensive overview of the

Get Price

Understanding LiFePO4 Lithium Batteries: A

What is LiFePO4? LiFePO4 stands for lithium iron phosphate, a chemical compound that forms the cathode material of these batteries. The basic

Get Price

Chinese LFP Battery Makers Expand Globally

Driven by a continuous surge in overseas orders, Chinese lithium iron phosphate (LFP) battery manufacturers are significantly ramping up their

Get Price

Status and prospects of lithium iron phosphate manufacturing in

Lithium iron phosphate (LiFePO 4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiveness as a cathode material.

Get Price

LFP Batteries | Electrek

Less than a week after announcing a Power Day 2023 event to unveil new battery technologies, ZEEKR has officially introduced its own

Get Price

The rise of Lithium Iron Phosphate batteries in Europe?

Strong investments in localized LFP production are expected to reduce reliance on Asian suppliers and to strengthen the region''s battery value chain. The European value chain is

Get Price

Slovenia lithium iron phosphate battery project

Envision Power''''s Spain plant will develop and manufacture the latest generation of lithium iron phosphate (LFP) battery products, which is expected to start production in 2026.

Get Price

The Slovenia Times

Battery maker TAB Mežica plans to open Slovenia''s first gigafactory for the production of battery storage systems in the northern town of Prevalje in 2024. The €18 million

Get Price

Slovenia lithium iron phosphate battery project

Is Morrow batteries Europe''s first major lithium-iron phosphate battery factory? (Bloomberg) — Morrow Batteries AS is opening the doors to Europe''s first major factory for lithium-iron

Get Price

Paving the way for US lithium-iron phosphate battery production

American Battery Factory recently announced a partnership with KAN Battery Co. to accelerate the development and production of lithium-iron phosphate (LFP) battery cells in

Get Price

Companies producing lithium batteries in Slovenia

Slovenian car battery manufacturer Tovarna Akumulatorskih Baterij (TAB) plans to launch production of lithium-ion batteries at its factory in Prevalje in February, local media reported.

Get Price

Lithium Iron Phosphate (LiFePO4 or LFP) Battery

Did you know that lithium iron phosphate (LiFePO4) batteries can last over 10 years—twice as long as standard lithium-ion? While most batteries degrade rapidly after 500

Get Price

Lithium Iron Phosphate Battery Market Size, Share & Growth

3 days ago· The global lithium iron phosphate battery market size surpassed USD 17.08 billion in 2025 and is projected to witness a CAGR of over 17.3%, crossing USD 84.23 billion revenue

Get Price

The World''s Largest Lithium Iron Manganese

The world''s largest lithium iron phosphate cathode material base has been put into production! Upgrading the performance of lithium iron

Get Price

6 FAQs about [Lithium iron phosphate battery production in Slovenia]

What is lithium iron phosphate (LiFePO4)?

Lithium iron phosphate (LiFePO4) has the advantages of environmental friendliness, low price, and good safety performance. It is considered to be one of the most promising cathode materials for lithium ion battery and has been widely used in electric vehicle power battery in China.

What are the synthesis methods of lithium iron phosphate?

The synthesis methods of lithium iron phosphate mainly include: solid phase method and liquid phase method. The solid phase method includes: high temperature solid phase reaction method, carbothermal reduction method, microwave synthesis method, mechanical alloying method.

Is lithium iron phosphate a good cathode material?

Lithium iron phosphate (LiFePO 4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiveness as a cathode material.

What is the reversible capacity of lithium iron phosphate cathode?

The lithium iron phosphate cathode prepared by it has a reversible capacity greater than 156mAh/g and excellent rate performance. In addition, the problems of poor low temperature performance, poor conductivity, and low capacity of the lithium iron phosphate positive electrode can also be improved.

What is lithium manganese iron phosphate (Lmfp)?

One promising approach is lithium manganese iron phosphate (LMFP), which increases energy density by 15 to 20% through partial manganese substitution, offering a higher operating voltage of around 3.7 V while maintaining similar costs and safety levels as LFP.

Which iron sources are used in LFP production?

For LFP production, commonly used iron sources include iron (II) phosphate (Fe 3 (PO 4) 2), iron oxalate (FeC 2 O 4), iron (III) phosphate (FePO 4 ⋅ x H 2 O), and iron oxides (e.g., Fe 2 O 3 and Fe 3 O 4). Iron sources are selected for their relative cost and compatibility with established synthetic techniques.

More related information

-

Mauritania lithium iron phosphate energy storage battery cabinet solution

Mauritania lithium iron phosphate energy storage battery cabinet solution

-

Production of lithium iron phosphate outdoor power cabinet

Production of lithium iron phosphate outdoor power cabinet

-

Lithium iron phosphate BMS battery

Lithium iron phosphate BMS battery

-

Lithium iron phosphate outdoor battery cabinet 220v

Lithium iron phosphate outdoor battery cabinet 220v

-

India lithium iron phosphate energy storage battery cabinet integrated system

India lithium iron phosphate energy storage battery cabinet integrated system

-

24v 50kWh lithium iron phosphate battery pack

24v 50kWh lithium iron phosphate battery pack

-

Greek energy storage lithium iron phosphate battery manufacturer

Greek energy storage lithium iron phosphate battery manufacturer

-

Belgian Energy Lithium Iron Phosphate Battery Pack

Belgian Energy Lithium Iron Phosphate Battery Pack

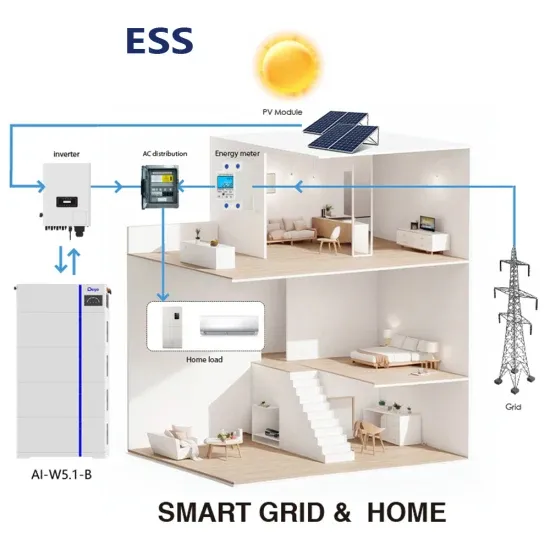

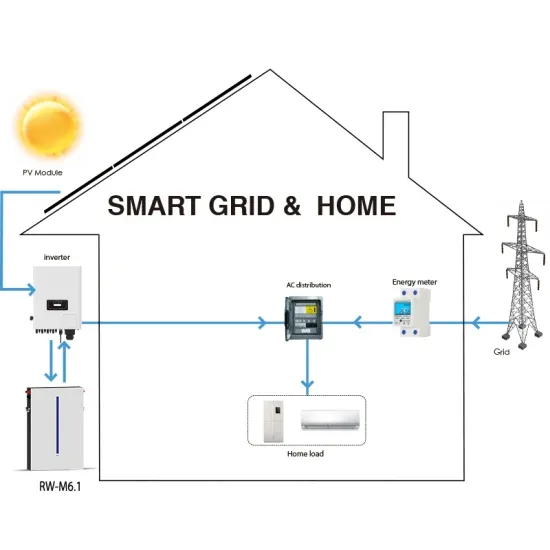

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.