Prefabricated Container Substation | META Power

View our prefabricated container substation product, which allows for mobility and rapid deployment. Join META Power Solutions online to learn more or contact

Get Price

STANDARD DESIGN CRITERIA FOR ELECTRICAL

To support this goal, a standardized design criteria for high-voltage electrical substations is proposed which outlines the key design inputs and considerations to ensure that the

Get Price

Solarcontainer: The mobile solar system

Mounted on this frame is the innovative PV rail system and the clever folding mechanism of the solar panels, which enable the transport dimensions and lifting points of a standard 20f high

Get Price

GENERAL SPECIFICATION FOR THE CIVIL SUB-03-025

Where works are proposed at existing substations and it is identified that existing civil assets have the potential to be utilised, a whole life cost analysis should be undertaken. Where a Primary

Get Price

GRID CONNECTED PV SYSTEMS WITH BATTERY

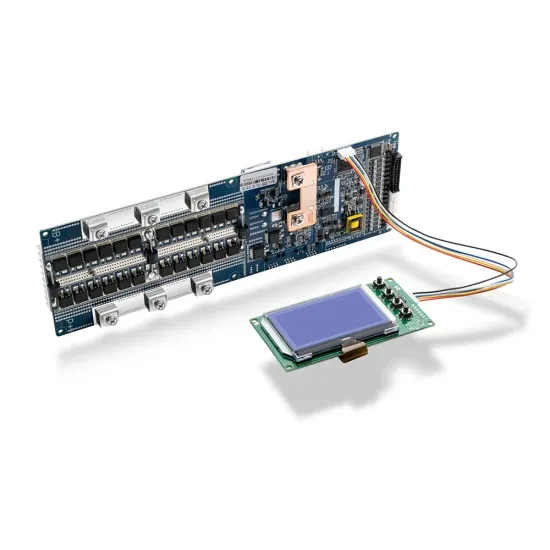

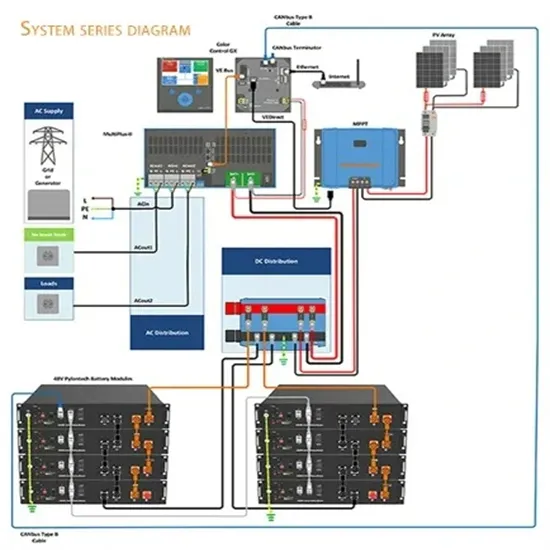

The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For example, some

Get Price

Containerized Substations

These factory-assembled and -tested solutions are ideally suited for permanent or semi-permanent usages. These include grid integration of renewable sources,

Get Price

Design Guide for Rural Substations

PURPOSE: This bulletin provides a basic design guide and a reference tool for designing rural substations. GENERAL: This Bulletin has been revised to bring the publication up to date with

Get Price

PV substation engineering and design — RatedPower

Easily choose your PV plant substation setup and access all necessary documents in a few clicks. Request a free demo.

Get Price

DESIGN AND IMPLEMENTATION OF FLOATING SOLAR

This paper focuses on the floating PV technology, describing the types of floating PV plant along with studies carried out on some floating solar plants. India, with huge energy demand and

Get Price

Offshore Substation General Requirements Functional

The Customer shall take account of emerging changes in standards, regulations and codes of practice and ensure that these are included in the design, supply, installation, testing and

Get Price

9_Containerised Substation

Containerised substations are designed in accordance with IS 14786 / IEC 61330 standards with degree of protection upto IP 43 for Transformer and Inverters compartments & upto IP 54 for

Get Price

Containerized Substations

These factory-assembled and -tested solutions are ideally suited for permanent or semi-permanent usages. These include grid integration of renewable sources, power supply to

Get Price

Compact digital substation container solutions

Smaller distribution substations are subdivided into container-sized modules, which can be manufactured, assembled and tested at the factory, allowing easy transport and fast

Get Price

What Certifications Should Solar Containers Have? A Buyers'' and

What certifications should solar containers have? Learn the key standards like IEC, UL, CE, and UN38.3 that ensure safety, compliance, and international deployment success.

Get Price

Medium voltage containerised power substations -Varelen

Medium voltage containerised power substations for the solar, mining, tunnelling and construction industries. Containers substation are offered as standard or bespoke packages to suit the

Get Price

NESC and ANSI Z535 Safety Sign Standards for Electric Utility Power

Both the NESC ANSI C2 rules and OSHA regulations require signs at appropriate places around utility facilities and workplaces. ANSI Z535 standards that specify the attributes of appropriate

Get Price

Prefabricated power solutions

Siemens Energy prefabricated power solutions are customized, prefabricated high-voltage substations that help save time and money both in temporary and permanent applications.

Get Price

Compact digital substation container solutions

Entering the digital age the development of our equipment is focused on highest standards for networking and communication. We ensure efficient and flexible communication under highest

Get Price

2030.2.1-2019

Scope: This document provides alternative approaches and practices for design, operation, maintenance, integration, and interoperability, including distributed resources

Get Price

11kv Mv Solar Power Package Substation

Conso Electrical Science and Technology Co., Ltd has engaged to fabricate 11kv compact substation, such as a 11kv mv solar power package substation. To produce a high quality 11kv

Get Price

Reference design guide xSolAir

The transformers inside our container solution can be designed to meet various global and industrial standards. For instance, they can be manufactured according to different loss levels,

Get Price

HANDBOOK FOR ENERGY STORAGE SYSTEMS

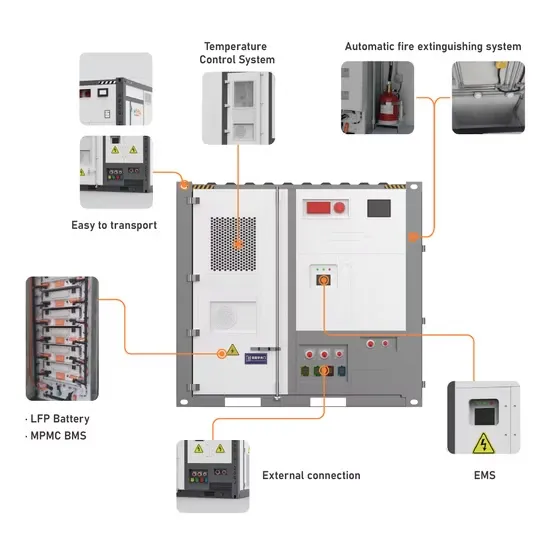

t, humid and urbanised environment. A 2.4 MW/2.4 MWh Lithium-Ion ESS was deployed in a substation as Si gapore''s first utility-scale ESS. Insights from this Test-bed helped to establish

Get Price

Container Substation

Container substation design can better adapt to all kinds of application environments, and improve product standardization design. They can also be

Get Price

Prefabricated Container Substation | META Power Solutions

View our prefabricated container substation product, which allows for mobility and rapid deployment. Join META Power Solutions online to learn more or contact us today to request a

Get Price

Containerized and prefabricated substations | Hitachi Energy

Smaller distribution substations are subdivided into container-sized modules, which can be manufactured, assembled and tested at the factory, allowing easy transport and fast

Get Price

Electrical Houses (eHouse)

Electrical House (eHouse) is a prefabricated walk-in modular enclosure to house a medium voltage and low voltage switchgear and auxiliary equipment.

Get Price

6 FAQs about [Photovoltaic container substation standards]

What are standardized design criteria for high-voltage electrical substations?

To support this goal, a standardized design criteria for high-voltage electrical substations is proposed which outlines the key design inputs and considerations to ensure that the substation is designed to comply with requirements.

What are the requirements for electrical substation design?

Compliance with applicable standards is a fundamental requirement in the design of electrical substations. This ensures that the substation is designed and built to a level of quality and safety that is accepted internationally. Standards to be complied with may include those from IEC, IEEE, and national standards organizations.

What is a container substation?

An intelligent solution for obtaining direct current quickly and economically is provided by container substations. By integrating the equipment in a modular housing and undertaking rigorous testing off site, Siemens is able to supply fully built and tested modular traction power substations to a consistent and high level of quality.

How do you design a high voltage substation?

Identify the key technical factors that should be considered in the design of high voltage substations and develop a set of standardized design criteria that can ideally be applied across different regions and contexts. Implement a case study of an example substation project for the application of the proposed standardized design criteria.

What should be included in the design of a substation?

Buildup could occur that would compromise electrical insulation or interfere with cooling. Appropriate prevention measures should be included in the design of a substation expected to be exposed to such contamination. Substations interface with roadways, area drainage, communications systems, and electric power lines.

What is the scope of a high voltage substation study?

Second, the scope of this study is exclusively on high voltage substations, thereby not extending to other critical components of the electrical power system such as transmission lines or power generating plants. This specialization allows for a deep dive into substation specifics but does not cover the broader power system infrastructure.

More related information

-

Belize photovoltaic container substation provider

Belize photovoltaic container substation provider

-

Costa Rica photovoltaic container substation price

Costa Rica photovoltaic container substation price

-

Mongolia photovoltaic container substation style

Mongolia photovoltaic container substation style

-

South Africa photovoltaic folding container factory wholesale

South Africa photovoltaic folding container factory wholesale

-

China-Europe photovoltaic container BESS

China-Europe photovoltaic container BESS

-

Mobile container photovoltaic panel installation

Mobile container photovoltaic panel installation

-

Photovoltaic communication base station energy storage system standards

Photovoltaic communication base station energy storage system standards

-

Cambodia Photovoltaic Energy Storage Container Project

Cambodia Photovoltaic Energy Storage Container Project

Commercial & Industrial Solar Storage Market Growth

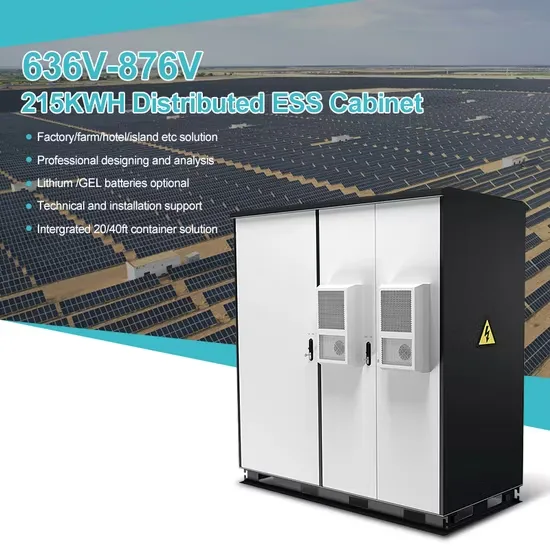

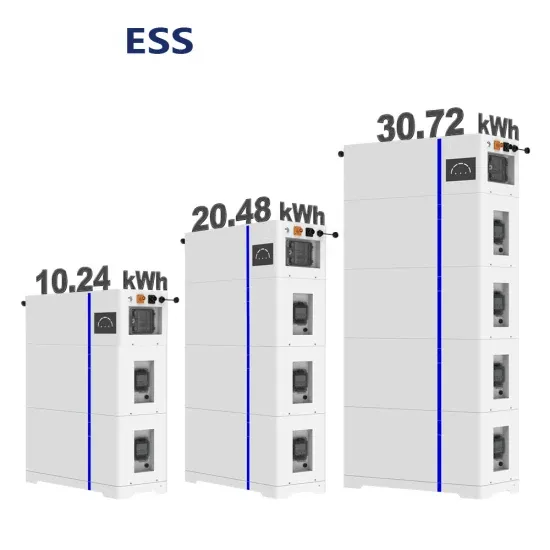

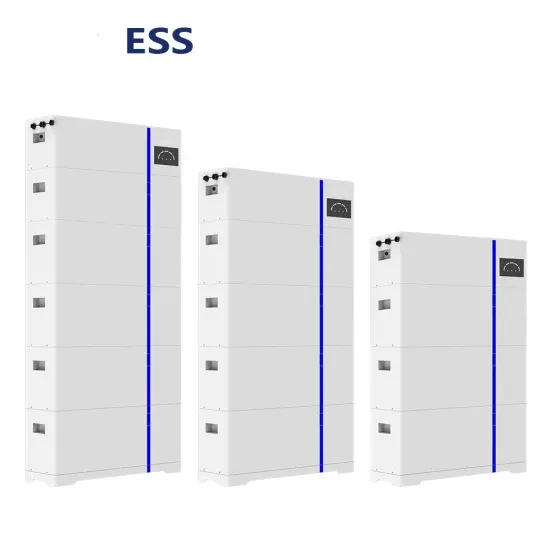

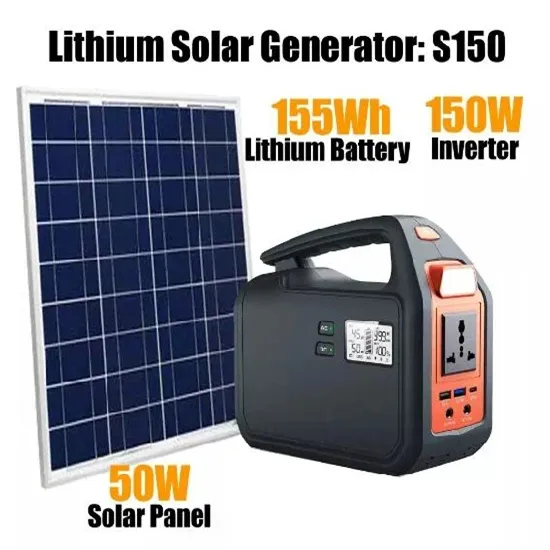

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.