Smoothing of wind power using flywheel energy

Flywheel systems are quick acting energy storage that enable smoothing of a wind turbine output to ensure a controllable power dispatch.

Get Price

What energy storage is used for wind power generation?

1. The predominant energy storage systems for wind power generation are battery storage, pumped hydro storage, and flywheel storage, which help address intermittency,

Get Price

A Review of Flywheel Energy Storage System

Additionally, earlier reviews do not include the most recent literature in this fast-moving field. A description of the flywheel structure and its main components

Get Price

Optimisation of a wind power site through utilisation of flywheel

This paper utilises real world data to simulate a wind farm operating in tandem with a Flywheel Energy Storage System (FESS) and assesses the effectiveness of different

Get Price

A flywheel in a wind turbine rotor for inertia control

In this paper, a flywheel energy storage that is an integral part of a wind turbine rotor is proposed. The rotor blades of a wind turbine are equipped with internal weights, which

Get Price

Flywheel Energy Storage System: What Is It and How Does It

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like composite carbon fiber, stores energy in

Get Price

Applications of flywheel energy storage system on load frequency

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Get Price

What energy storage is used for wind power generation?

Flywheel energy storage represents another innovative solution for wind power generation. This technology converts electrical energy into kinetic energy by spinning a rotor in

Get Price

What energy storage is used for wind power generation?

Flywheel energy storage represents another innovative solution for wind power generation. This technology converts electrical energy into

Get Price

Flywheel Energy Storage System: What Is It and How

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like

Get Price

(PDF) Energy Storage in Flywheels: An Overview

This paper presents an overview of the flywheel as a promising energy storage element. Electrical machines used with flywheels are surveyed

Get Price

Flywheel energy storage controlled by model predictive control to

The use of energy storage systems to improve the fluctuation of wind power generation has garnered significant in the development of wind power. However, the

Get Price

Flywheel Energy Storage (FES) Systems

Flywheel Energy Storage (FES) systems are intriguing solutions in the broad spectrum of energy storage technologies. In an era where the

Get Price

Flywheel storage power system

Sectional view of a flywheel storage with magnetic bearings and evacuated housing A flywheel-storage power system uses a flywheel for grid energy

Get Price

Design of a flywheel energy storage system for wind power

Flywheel energy storage system (FESS) will be needed at different locations in the wind farm, which can suppress the wind power fluctuation and add value to wind energy. A

Get Price

Active power control of a flywheel energy storage system for wind

The integration of wind power generation in power systems is steadily increasing around the world. This incorporation can bring problems onto the dynamics of power systems

Get Price

Review of flywheel energy storage systems for wind power

Compared with other energy storage technologies, flywheel energy storage (FES) has advantages of high round-trip efficiency and little environmental impact. FES is capable of

Get Price

How to Store Wind Energy: Top Solutions Explained

Wind energy storage solutions are vital for optimizing energy use, but which methods truly maximize efficiency and reliability? Discover the top

Get Price

Overview of energy storage systems for wind power integration

Energy storage systems are considered as a solution for the aforementioned challenges by facilitating the renewable energy sources penetration level, reducing the voltage

Get Price

Development and prospect of flywheel energy storage

With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

Get Price

Smoothing of wind power using flywheel energy storage system

Abstract: Flywheel systems are quick acting energy storage that enable smoothing of a wind turbine output to ensure a controllable power dispatch. The effectiveness of a flywheel

Get Price

Flywheel energy storage technologies for wind energy systems

There are already some applications of high-power and low- energy flywheel systems for smoothing wind power fluctuations in weak networks, and new requirements are

Get Price

A review of flywheel energy storage systems: state of the art

Energy storage systems (ESS) play an essential role in providing continu-ous and high-quality power. ESSs store intermittent renewable energy to create reliable micro-grids

Get Price

Flywheel energy storage

In 2010, Beacon Power began testing of their Smart Energy 25 (Gen 4) flywheel energy storage system at a wind farm in Tehachapi, California. The system

Get Price

Operation of a Wind Turbine-Flywheel Energy Storage System

Flywheel energy storage was selected due to its characteristics and technical parameters. The storage capacity was determined based on an empirical relationship using

Get Price

Flywheel energy storage

In 2010, Beacon Power began testing of their Smart Energy 25 (Gen 4) flywheel energy storage system at a wind farm in Tehachapi, California. The system was part of a wind power and

Get Price

Flywheel energy storage systems: Review and simulation for an

In flywheel based energy storage systems (FESSs), a flywheel stores mechanical energy that interchanges in form of electrical energy by means of an electrical machine with a

Get Price

Smoothing of wind power using flywheel energy storage system

Flywheel systems are quick acting energy storage that enable smoothing of a wind turbine output to ensure a controllable power dispatch. The effectiveness of a flywheel

Get Price

6 FAQs about [What wind power can be used for flywheel energy storage]

What is a flywheel energy storage system?

Flywheel energy storage systems provide a solution to the problems encountered in high-penetration hybrid power systems, providing power smoothing in the range of seconds to minutes.

Does Beacon Power have a flywheel energy storage system?

In 2010, Beacon Power began testing of their Smart Energy 25 (Gen 4) flywheel energy storage system at a wind farm in Tehachapi, California. The system was part of a wind power and flywheel demonstration project being carried out for the California Energy Commission.

Are flywheels a good choice for wind farms?

There are already some applications of high-power and low- energy flywheel systems for smoothing wind power fluctuations in weak networks, and new requirements are emerging for stability improvement and protection of wind farms against network voltage dips. These applications are ideally suited to the high-power cycling capabilities of flywheels.

Should you use a flywheel or a battery energy storage system?

Both technologies have their merits, but the choice between a flywheel or a battery energy storage system largely depends on your needs: Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure.

Can a wind turbine-flywheel energy storage system operate under real conditions?

The paper presents the issues of a wind turbine-flywheel energy storage system (WT-FESS) operating under real conditions. Stochastic changes of wind energy in time cause significant fluctuations of the system output power, which negatively impacts the quality of the generated electrical energy.

How much energy can a flywheel store?

A flywheel constructed by Urenco Power Technologies (UPT) ( Tarrant, 1998) using the filament wind process had a cylindrical rotor of mass 110 kg, and energy storage capacity of 2 kW h when operated at up to 37 800 rev/min. The construction of this flywheel is shown in Fig. 11.2.

More related information

-

What is flywheel energy storage wind power

What is flywheel energy storage wind power

-

What batteries are used in large energy storage power stations

What batteries are used in large energy storage power stations

-

What does wind power and solar energy storage mean

What does wind power and solar energy storage mean

-

What batteries are used in energy storage power stations

What batteries are used in energy storage power stations

-

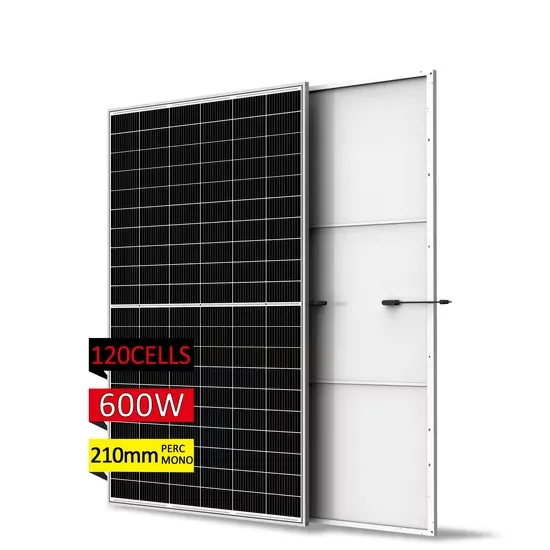

What energy storage is used for photovoltaic power generation

What energy storage is used for photovoltaic power generation

-

What are the wind power energy storage power stations

What are the wind power energy storage power stations

-

What is energy storage and grid-connected power generation

What is energy storage and grid-connected power generation

-

Energy storage requirements for Angola wind power projects

Energy storage requirements for Angola wind power projects

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.