Global Standards Certifications for BESS

Here''s a breakdown of key standards at each level: IEC 62619 and IEC 63056 ensure safety and performance for industrial lithium-ion cells.

Get Price

National Blueprint for Lithium Batteries 2021-2030

Lithium-based batteries power our daily lives from consumer electronics to national defense. They enable electrification of the transportation sector and provide stationary grid storage, critical to

Get Price

Energy Storage Battery Manufacturing Key Processes – Cell Sorting

Lithium cell sorting is a crucial manufacturing process that categorizes battery cells to ensure maximum consistency in performance across a battery pack. This enhances overall efficiency,

Get Price

Energy storage cell standards

Covers the sorting and grading process of battery packs, modules and cells and electrochemical capacitors that were originally configured and used for other purposes, such as electric vehicle

Get Price

Deep sorting of reused batteries for enabling long-term

When reusing batteries retired from electric vehicles, the main challenge lies in accurately grouping cells to ensure long-term consistency, especially given their unknown

Get Price

Battery Cell Sorting for Safer, Efficient Battery Packs

Battery cell sorting improves performance and safety. Find out why it''s essential and how the process works for better battery efficiency.

Get Price

Codes & Standards Draft – Energy Storage Safety

Covers the sorting and grading process of battery packs, modules and cells and electrochemical capacitors that were originally configured and used for other purposes, such as electric vehicle

Get Price

What is Battery Cell Sorting, Why is it Required, and How to Do It?

For professionals seeking to optimize battery performance, understanding the principles and technologies behind cell sorting provides valuable insight into a critical quality

Get Price

What is Battery Cell Sorting, Why is it Required, and

For professionals seeking to optimize battery performance, understanding the principles and technologies behind cell sorting provides

Get Price

D4.4 List of commercial cells

Li-ion batteries are excellent storage systems because of their high energy and power density, high cycle number and long calendar life. However, such Li-ion energy storage systems have

Get Price

Energy storage battery sorting standards

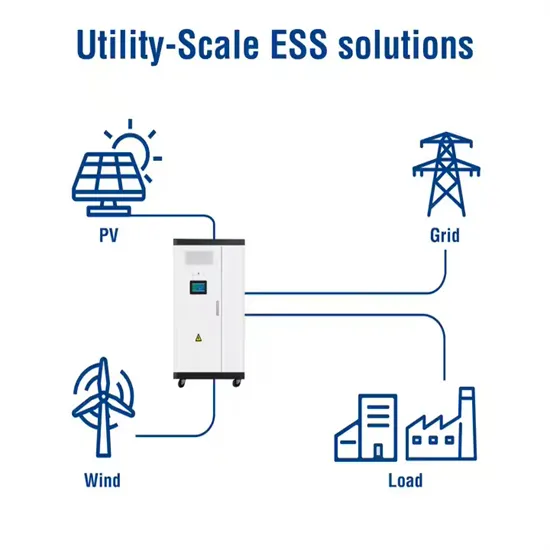

This document provides an overview of current codes and standards (C+S) applicable to U.S. installations of utility-scale battery energy storage systems.

Get Price

Sorting and grouping method for lithium ion batteries

The invention relates to the technical field of lithium ion battery manufacturing, and particularly relates to a sorting and grouping method for lithium ion batteries. The sorting and grouping

Get Price

Prismatic Battery Cell Sorting Machine for EV Production

Ensure long-term EV battery performance with a Prismatic Battery Cell Sorting Machine that matches cells by capacity, resistance, voltage &

Get Price

Energy Storage System Guide for Compliance with Safety

One of three key components of that initiative involves codes, standards and regulations (CSR) impacting the timely deployment of safe energy storage systems (ESS). A CSR working group

Get Price

Sorting and grouping optimization method for second-use

The multi-factor sorting method considering capacity, internal resistance and aging mechanism is presented.

Get Price

A new method for lithium-ion battery uniformity sorting based on

Due to the voltage and current limitations, a single battery cell is unable to meet the power and energy requirements in most applications and, therefore, battery cells need to be

Get Price

Global Standards Certifications for BESS

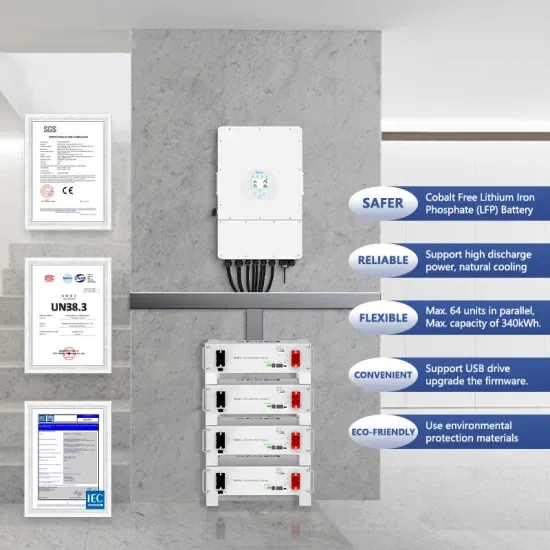

Here''s a breakdown of key standards at each level: IEC 62619 and IEC 63056 ensure safety and performance for industrial lithium-ion cells. UL 1642 and UN 38.3 verify

Get Price

Global Standards Certifications for BESS

he Global Standards Certifications for BESS container based solutions is significant. As Battery Energy Storage Systems become critical to

Get Price

A two-stage sorting method combining static and dynamic

The battery echelon utilization is to sort and reuse the retired lithium-ion batteries with poor consistency, which puts forward higher requirements on how to guarantee their

Get Price

Challenges and Innovations With Spent Battery Sorting

Battery sorting plays a crucial role in recycling, but is inhibited by challenges such as a lack of automation and battery standardization. This review examines current sorting

Get Price

How to Differentiate Between A, B, and C-Grade

Battery cells are the core components of energy storage systems, directly impacting the reliability, safety, and lifespan of end products. However,

Get Price

Prismatic Cell Sorting Machine for Lithium Battery Quality

Improved Efficiency: By automating the sorting process, manufacturers can process thousands of cells daily, significantly reducing labor costs and errors.

Get Price

Energy storage battery sorting standards

Abstract: Application of this standard includes: (1) Stationary battery energy storage system (BESS) and mobile BESS; (2) Carrier of BESS, including but not limited to

Get Price

Deep sorting of reused batteries for enabling long-term

Wang et al. develop a deep sorting method for grouping reused lithium-ion batteries based on implicit features extracted from single-charge-cycle tests. Their approach enables

Get Price

The Significance of Cell Sorting in EV Battery Technology

Through advanced and precise sorting techniques, EV manufacturers can achieve higher accuracy levels, ensuring that each battery pack meets stringent quality standards. Improved

Get Price

Lithium battery sorting method for high-rate operating conditions

In order to meet the energy and power requirements of large-scale battery applications, lithium-ion batteries have to be connected in series and parallel to form various

Get Price

6 FAQs about [Sorting standards for energy storage battery cells]

How a battery pack is used in energy storage condition?

The battery pack used in energy storage condition contains 6 cells connected in series, and the cells are obtained by using the multi-factor sorting method (the closest to the center point) and obtained by a single capacity factor respectively.

How to sort retired batteries?

At present, there is no recognized effective sorting method for retired batteries, and most of them still take capacity and internal resistance as sorting criteria, which is utilized for fresh batteries sorting after they are produced.

What is a battery management standard?

A new standard that will apply to the design, performance, and safety of battery management systems. It includes use in several application areas, including stationary batteries installed in local energy storage, smart grids and auxillary power systems, as well as mobile batteries used in electric vehicles (EV), rail transport and aeronautics.

How do you classify a battery in multi-factor sorting?

The sample (battery) with the minimum euclidean distance to the corresponding center point indicates that it is included in this category. Therefore, all the samples with three characteristic parameters (capacity, internal resistance and LAM) can be classified into different categories to achieve multi-factor sorting for retired batteries. 3.2.

Why do I need to sort second-use batteries?

Sorting of second-use batteries is a necessary before grouping. Many factors, such as operating conditions, ambient temperature and cell inconsistency will affect the cell aging. Therefore, sorting factors for second-use batteries are needed to ensure the pack performance and satisfy the requirement for second-use operation.

What is a battery standard?

Covers requirements for battery systems as defined by this standard for use as energy storage for stationary applications such as for PV, wind turbine storage or for UPS, etc. applications.

More related information

-

What kind of battery cells are generally used in energy storage systems

What kind of battery cells are generally used in energy storage systems

-

Battery Cells and Energy Storage

Battery Cells and Energy Storage

-

Egypt Energy Storage Battery Standards

Egypt Energy Storage Battery Standards

-

Battery cells for home energy storage

Battery cells for home energy storage

-

Battery cells contribute to the cost of energy storage

Battery cells contribute to the cost of energy storage

-

Photovoltaic energy storage battery wall mount

Photovoltaic energy storage battery wall mount

-

Ukrainian home energy storage battery company

Ukrainian home energy storage battery company

-

Solar lithium battery energy storage price

Solar lithium battery energy storage price

Commercial & Industrial Solar Storage Market Growth

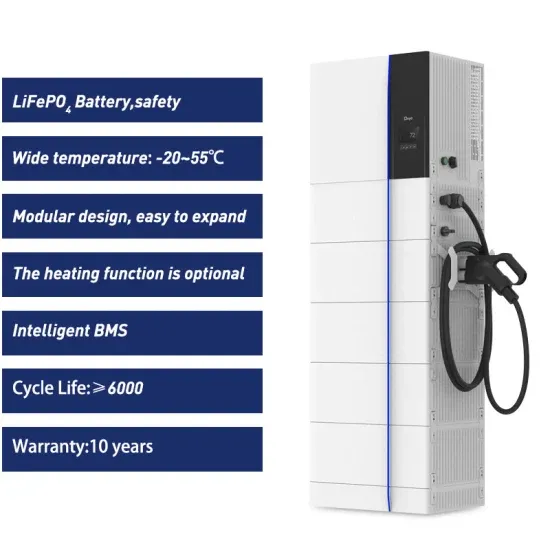

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.