Is an inverter required if you''re used a DC motor?

Question An inverter is used to invert DC from the battery pack into AC for the motor. But if you''re using a DC motor, is an inverter even needed?

Get Price

Brushless DC Motor Buying Guide | Brushless

A brushless DC motor (BLDC) is a synchronous motor that uses a DC power source. The brushless DC motor is essentially a permanent magnet

Get Price

EV Inverter Technology Explained: A Comprehensive Guide for

Find out about EV inverter technology: how it powers electric motors, enables regenerative braking, and improves efficiency. A must-read guide for UK mechanics!

Get Price

What is an Inverter in Electric Vehicle? What Does It Do in EV Car?

Conclusion The inverter in electric vehicles is a cornerstone of EV technology, enabling efficient power conversion, motor control, and energy regeneration. As EV adoption

Get Price

Exploring Motor Control Terms: What is an Inverter?

To properly understand why a Motor Control is sometimes called an inverter one must first understand some basic principles behind this type of motor control.

Get Price

What is a digital inverter motor in the washing machine?

Do all washing machines have digital inverter motors? A digital inverter motor is usually installed on higher-end models, and they are

Get Price

How Inverters Work

A common and fairly simple application of inverters is within photovoltaic arrays, as these generate DC power, but, the appliances in your

Get Price

How do inverters convert DC electricity to AC?

Inverters waste energy converting DC power to AC, and there are plenty of other losses in power generation and distribution, so why not simply

Get Price

Electric Motor Inverter Explained

In this article we''ll explore how an electric motor inverter works, breaking down complex engineering principles into clear, actionable insights for automotive engineers, EV

Get Price

Converting DC to AC: Basic Principles of Inverters

This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical engineering. These can also be known as

Get Price

Understanding the Distinction Between AC Drives and Inverters

While AC drives are a type of inverter, not all inverters serve the function of motor speed control. In the context of motor control, inverters typically refer to devices that convert

Get Price

The Role of Inverters and Power Electronics in EV

The interplay between inverters and other power electronic components ensures the efficient operation of the EV powertrain. Key

Get Price

What Does An Inverter Do? Complete Guide To

Learn what inverters do, how they convert DC to AC power, types available, and applications. Complete guide with sizing tips, safety advice, and

Get Price

What are Inverters and AC Input Brushless DC Motors?

Inverters are used in combination with a three-phase 200 VAC motors to control the rotation speed by changing the power supply frequency. All you need to connect is a power supply and

Get Price

What Is a Traction Inverter? EV Inverters Explained

Consequently, traction inverters can be found in all types of electric land vehicles, including trains, mining equipment, and increasingly, cars and trucks. There

Get Price

Converting DC to AC: Basic Principles of Inverters

This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC voltage in manufacturing.

Get Price

What is an Inverter? Working Principle, Types, and

Voltage Source Inverter (VSI): Utilizes a constant DC voltage as input and converts it into AC. This type is commonly used in applications requiring

Get Price

How do inverters convert DC electricity to AC?

Inverters waste energy converting DC power to AC, and there are plenty of other losses in power generation and distribution, so why not simply supply low-voltage DC power to

Get Price

How Do Inverters Work?

A very common use of inverters is in photovoltaic arrays since the output of these generators is DC, while all major appliances use AC power. A

Get Price

How Inverters Work

A common and fairly simple application of inverters is within photovoltaic arrays, as these generate DC power, but, the appliances in your home will use AC power so this needs

Get Price

Inverters in Electric Vehicles: Powering the Next Generation of

Learn how inverters in electric vehicles power the next generation of transportation by converting DC to AC, optimizing efficiency, and supporting renewable energy integration.

Get Price

What Does an Inverter Do

Inverters are also called AC Drives, or VFD (variable frequency drive). They are electronic devices that can turn DC (Direct Current) to AC (Alternating

Get Price

What Does An Inverter Do? Complete Guide To Power Conversion

Learn what inverters do, how they convert DC to AC power, types available, and applications. Complete guide with sizing tips, safety advice, and expert insights.

Get Price

Brushless DC Motors (BLDC Motors) vs. Servo

The brushless DC gear motor is growing in popularity in the world of speed control. However, not everyone is familiar with the power and performance to

Get Price

Why does a Tesla car use an AC motor instead of a

I was just watching a mega factory video and wondered why they use an AC motor which requires a power inverter instead of DC which may be powered

Get Price

ECM, VFD, and Inverter

ECM (Electronically Commutated Motor) In residential and light commercial HVAC, we have seen ECM (Variable-Speed/X13) motors for

Get Price

What Does an Inverter Do

Inverters are also called AC Drives, or VFD (variable frequency drive). They are electronic devices that can turn DC (Direct Current) to AC (Alternating Current). It is also responsible for

Get Price

6 FAQs about [Do all DC motors have inverters ]

Which type of inverter is used to control electric motors?

They are used in a number of applications both in industry and everyday life. There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical engineering. These can also be known as AC drives, variable speed drives (VSD), and variable frequency drives (VFD).

Why do we need to convert between a DC and AC inverter?

Both types of power have their uses and limitations so we often need to convert between the two to maximise their use. An inverter is a device which is used to convert between Direct Current (DC) and Alternating Current (AC).

Do inverters waste energy converting DC to AC?

IEEE Spectrum, February 6, 2014. Inverters waste energy converting DC power to AC, and there are plenty of other losses in power generation and distribution, so why not simply supply low-voltage DC power to homes to begin with? [PDF] Performance of PV Inverters by Frank Vignola et al. Solar Radiation Monitoring Lab, University of Oregon.

Where are inverters used?

There are many uses for inverters and common places where one might find an inverter, including: Traditionally DC power conversion was achieved through a motor generator set, where a motor operating on DC power directly turned a generator to produce the required AC power.

How are inverters categorized based on the type of AC power?

Inverters can be categorized based on the type of AC power they produce. AC power generated by the grid is of a pure sinusoidal shape and alternates smoothly between high and low voltage according to the shape of a sine wave.

What do you need to know about inverters & brushless DC motors?

Well, first of all, you need to know the features of inverters and brushless DC motors. Ms. Ori! First of all, could you tell me about the features of the inverter? Inverters are used in combination with a three-phase 200 VAC motors to control the rotation speed by changing the power supply frequency.

More related information

-

DC inverters in Nigeria

DC inverters in Nigeria

-

What is the best DC voltage for photovoltaic inverters

What is the best DC voltage for photovoltaic inverters

-

There are two types of DC inverters

There are two types of DC inverters

-

What are the categories of DC inverters

What are the categories of DC inverters

-

Installation of energy storage cabinets for communication base station inverters

Installation of energy storage cabinets for communication base station inverters

-

New photovoltaic inverters in Zimbabwe

New photovoltaic inverters in Zimbabwe

-

Regular inspection of photovoltaic inverters

Regular inspection of photovoltaic inverters

-

All supporting equipment for photovoltaic inverters

All supporting equipment for photovoltaic inverters

Commercial & Industrial Solar Storage Market Growth

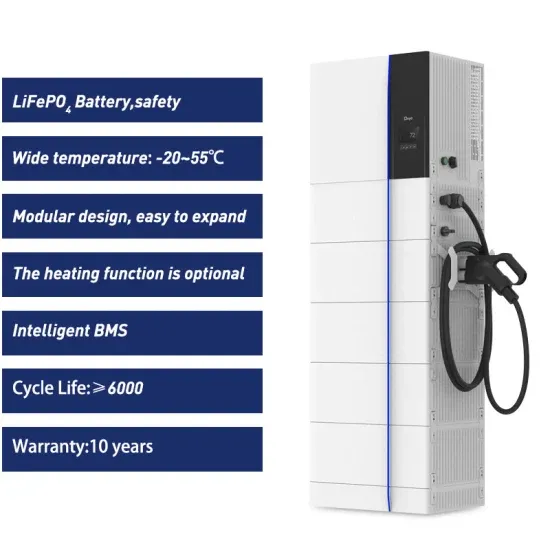

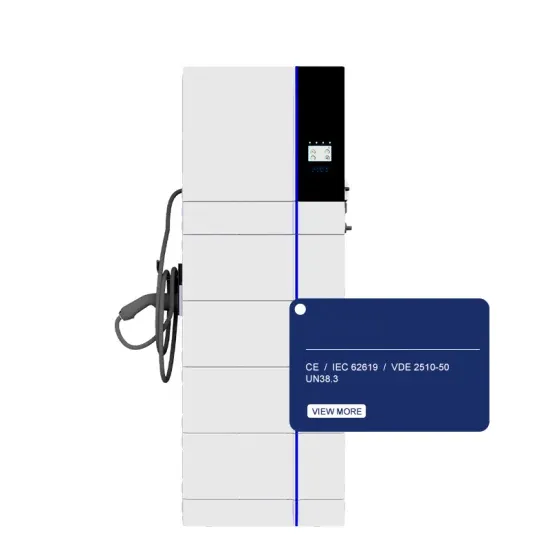

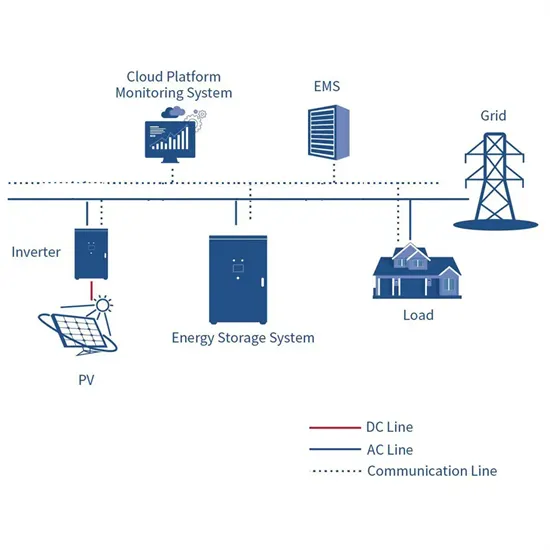

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.