Latent thermal energy storage technologies and applications: A

PCMs allow the storage of latent thermal energy during phase change at almost stable temperature. The article presents a classification of PCMs according to their chemical

Get Price

Fundamentals of high-temperature thermal energy storage,

Latent heat storage is connected to phase transition of the storage materials (phase change materials, PCMs), typically changing their physical phase from a solid to liquid and

Get Price

Review on operation control of cold thermal energy storage in

This review provides an overview and recent advances of the cold thermal energy storage (CTES) in refrigeration cooling systems and discusses the operation control for

Get Price

Design of a New Compressed Air Energy Storage System with Constant

The new system combines pumped-hydro and compressed-air methods, and features constant air pressure and temperature. Another specific character of the system is the usage of flexible

Get Price

Design of Battery Management System for Grid Energy Storage

A battery management system design and test scheme are proposed to meet the test requirements for high-precision state-of-energy (SOE) calculation in energy sto

Get Price

Constant Temperature Control System of Energy Storage Battery

Constant Temperature Control System of Energy Storage Battery for New Energy Vehicles based on Fuzzy Strategy Published in: 2020 IEEE International Conference on Industrial Application

Get Price

Why Constant Temperature Control is the Unsung Hero of

Did you know that over 60% of battery-related fires in energy storage systems occur due to poor temperature management? As global energy storage capacity surpasses 500 GWh in 2025,

Get Price

Fundamentals of high-temperature thermal energy storage, transfer

Latent heat storage is connected to phase transition of the storage materials (phase change materials, PCMs), typically changing their physical phase from a solid to liquid and

Get Price

Why Constant Temperature Control is the Unsung Hero of Energy Storage

Did you know that over 60% of battery-related fires in energy storage systems occur due to poor temperature management? As global energy storage capacity surpasses 500 GWh in 2025,

Get Price

Working principle of energy storage liquid constant temperature

In most cases, storage is based on a solid/liquid phase change with energy densities on the order of 100 kWh/m3 (e.g. ice). Thermo-chemical storage (TCS) systems can reach storage

Get Price

Numerical Investigation of Thermal Energy Storage

This study aims to investigate and identify the most effective thermal energy storage (TES) system configuration for the collective heating

Get Price

Energy storage constant temperature water tank

storage ponds, particularly in coastal areas. Also, in this system, a high-temperature energy storage (HTES) unit is used instead of a conventional combustion chamber to reduce

Get Price

What are the latent heat constant temperature energy

Latent heat storage materials play a crucial role in sustainability by enhancing energy efficiency and reducing thermal energy wastage. By

Get Price

Constant mixing temperature test of a fin-and-tube

This article presents a design of a fin-and-tube latent heat thermal energy storage (LHTES), which combines high thermal energy storage density

Get Price

Cold thermal energy storage – SINTEF Blog

The main benefit of PCMs related to CTES for refrigeration systems is the possibility to store and release thermal energy at a constant temperature, which matches the

Get Price

Exploration of new function for thermal energy storage:

Thermal energy storage (TES) is a technology that stores thermal energy by heating or cooling a storage medium so that the stored energy can be used when needed.

Get Price

Cold thermal energy storage – SINTEF Blog

The main benefit of PCMs related to CTES for refrigeration systems is the possibility to store and release thermal energy at a constant

Get Price

Liquid–gas cryogenic energy storage units operating at constant temperature

Abstract The cryogenic energy storage unit described in this article is a device that is able to absorb heat at constant temperature and that provides some significant advantages

Get Price

Exploration of new function for thermal energy storage: Temperature

Thermal energy storage (TES) is a technology that stores thermal energy by heating or cooling a storage medium so that the stored energy can be used when needed.

Get Price

Constant temperature energy storage

What is a thermal energy storage system? Renewable energy generation is inherently variable. For example, solar energy shows seasonal (summer–winter), daily (day–night), and hourly

Get Price

A comprehensive review on the recent advances in materials for

The three mechanisms of thermal energy storage are discussed herein: sensible heat storage (Q S,stor), latent heat storage (Q L,stor), and sorption heat storage (Q SP,stor).

Get Price

Latent Heat Thermal Energy Storage

LHTES, or latent heat thermal energy storage, refers to a technology that stores thermal energy during the phase change of materials from solid to liquid at a constant temperature, providing

Get Price

Liquid–gas cryogenic energy storage units operating at constant

A closed system able to store thermal energy at constant temperature was successfully tested in the 77–81 K temperature range. It can be used as a vibration-free

Get Price

Performance assessment of compressed air energy storage systems

In this study, two integrated hybrid solar energy-based systems with thermal energy storage options for power production are proposed, thermodynamically analyzed and

Get Price

Compressed-air energy storage

Diabatic storage dissipates much of the heat of compression with intercoolers (thus approaching isothermal compression) into the atmosphere as waste,

Get Price

Thermal performance investigation of a medium-temperature pilot

In addition, the LHTES system achieved accumulative energy storage of 993.64 MJ and release of 659.58 MJ with a cycle efficiency of 66.38% under the constant temperature

Get Price

Findings from Storage Innovations 2030: Compressed Air

About Storage Innovations 2030 This technology strategy assessment on compressed air energy storage (CAES), released as part of the Long-Duration Storage Shot, contains the findings

Get Price

Liquid–gas cryogenic energy storage units operating at constant temperature

A closed system able to store thermal energy at constant temperature was successfully tested in the 77–81 K temperature range. It can be used as a vibration-free

Get Price

Working principle of energy storage liquid constant temperature system

In most cases, storage is based on a solid/liquid phase change with energy densities on the order of 100 kWh/m3 (e.g. ice). Thermo-chemical storage (TCS) systems can reach storage

Get Price

6 FAQs about [Energy storage constant temperature system]

What is cold thermal energy storage (CTEs)?

Cold thermal energy storage (CTES) is a technology that relies on storing thermal energy at a time of low demand for refrigeration and then using this energy at peak hours to help reduce the electricity consumption of the refrigeration system.

How can thermal energy be stored?

The storage of thermal energy is possible by changing the temperature of the storage medium by heating or cooling it. This allows the stored energy to be used at a later stage for various purposes (heating and cooling, waste heat recovery or power generation) in both buildings and industrial processes.

When is thermal energy storage implemented?

Looking at the situation when thermal energy storage is implemented gives a completely different picture: cold thermal energy can be stored by operating the refrigeration system during off-peak periods (nights, weekends). During peak hours, a part of the thermal load is covered by the storage and the rest is covered by the refrigeration system.

What is a thermal energy storage system?

Renewable energy generation is inherently variable. For example, solar energy shows seasonal (summer–winter), daily (day–night), and hourly (clouds) variations. Thermal energy storage (TES) systems correct this mismatch between the supply and demand of the thermal energy.

What are the different methods of thermal energy storage?

The article presents different methods of thermal energy storage including sensible heat storage, latent heat storage and thermochemical energy storage, focusing mainly on phase change materials (PCMs) as a form of suitable solution for energy utilisation to fill the gap between demand and supply to improve the energy efficiency of a system.

Which temperature is best for thermal storage?

It is discovered that for air-conditioning and refrigeration applications temperatures of around −5 to 15 °C are ideal for thermal storage , , , but at lower temperatures, phase change based heat storage materials are better than reactive substances such as water.

More related information

-

Outdoor Energy Storage Constant Temperature Cabinet

Outdoor Energy Storage Constant Temperature Cabinet

-

Kosovo energy storage low temperature lithium battery

Kosovo energy storage low temperature lithium battery

-

Energy storage cabinet temperature

Energy storage cabinet temperature

-

Flywheel energy storage temperature and humidity

Flywheel energy storage temperature and humidity

-

Uruguay energy storage temperature control price

Uruguay energy storage temperature control price

-

Malaysian energy storage temperature control system manufacturer

Malaysian energy storage temperature control system manufacturer

-

Energy storage temperature control products

Energy storage temperature control products

-

Internal temperature of liquid-cooled energy storage container in summer

Internal temperature of liquid-cooled energy storage container in summer

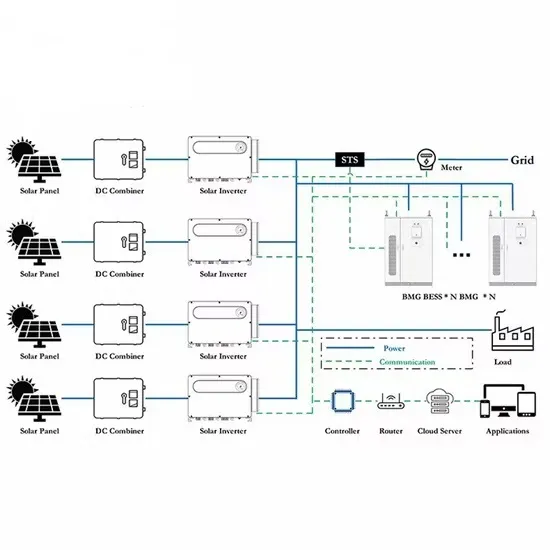

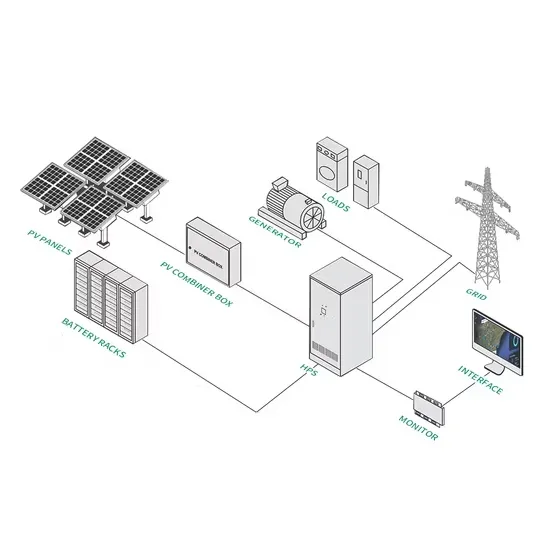

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.