BASF and Worldlight''s New Polyurethane-based PV Module Frame

Aiming towards a more sustainable plastic use in future BASF and Worldlight''s new polyurethane-based PV module frame is the newest addition in the industry. With better

Get Price

Dual-temperature responsive phase change waterborne polyurethane

Against the backdrop of rapidly increasing global energy consumption, the overreliance on traditional fossil fuels has triggered severe energy crises and environmental pollution, driving

Get Price

polyurethane solar panel frame

According to the national standard "Photovoltaic building integrated system lightning protection technical specification", photovoltaic frame is an insulation

Get Price

Polyurethane system makes better frames for photovoltaic panels

The PU is cast directly onto the solar cell by reaction injection moulding. The solar cells and collectors are placed into a closed mould and COLO-FAST PU is injected. After a

Get Price

The non-metallic frame for photovoltaic modules is

This post is talking about the current and new material for the frame of solar panels. It refers to aluminum solar frames and non-metallic

Get Price

Are Polyurethane Panels Good for Photovoltaics? Let''s Break It

This quirky analogy perfectly captures the current divide in photovoltaic (PV) component choices. Let''s explore whether these polymer-based solutions truly shine or if they''re just another flash

Get Price

Polyurethane Solar Solutions

BASF engineering plastics for solar mounting systems, panel frames, utility tracking & power electronics If you traditionally design in metal, BASF engineers and scientists can assist you

Get Price

Polyurethane Formulations Enhance Solar Module Durability

Explore how advanced polyurethane formulations improve the durability and performance of solar modules, offering enhanced resistance to environmental factors and extending module lifespan.

Get Price

Sustainable PU Composite Solar Panel Frames | Covestro

The polyurethane (PU) composite solar panel frame, jointly developed by Covestro and its partners, provides a new solution for the selection of frame materials for photovoltaic (PV)

Get Price

Adhesives for Solar Panel Manufacturing & Installation

Are Solar Panels the Future of Sustainable Energy? As the UK government pushes for carbon neutrality by 2050, innovation is being forced

Get Price

Dynamic Duo: Optimizing the performance of spray polyurethane foam

Spray Polyurethane Foam (SPF) and PV systems are increasingly paired together as a joint solution for energy savings.

Get Price

News

A solar panel sealant is an adhesive material designed to form a strong barrier between a photovoltaic (PV) module and its frame or mounting system. These

Get Price

Sustainable polyurethane composite materials: Innovative solar

Polyurethane composite solar panel frames demonstrate outstanding material performance. As a non-metallic material, polyurethane composite materials are made of a high-density

Get Price

How to apply glue to solar photovoltaic panels

To effectively apply glue to solar photovoltaic panels, one must follow a series of crucial steps and adhere to specific guidelines to ensure a

Get Price

High-Efficiency polyurethane solar panel

Go for efficient and robust polyurethane solar panel at Alibaba for both residential and commercial uses. Buy amazing polyurethane solar panel having mono, poly and photovoltaic

Get Price

Polyurethane Solar Solutions

BASF engineering plastics are widely used in solar applications, such as mounting systems, solar panels and components. These materials offer design flexibility, light weight, corrosion

Get Price

BASF and Worldlight''s New Polyurethane-based PV

Aiming towards a more sustainable plastic use in future BASF and Worldlight''s new polyurethane-based PV module frame is the newest addition

Get Price

BASF, Worldlight release new PV module frame

BASF and Worldlight have developed a new PV module frame based on polyurethane. The manufacturers claim that the new solution offers

Get Price

Sustainable PU Composite Solar Panel Frames

The polyurethane (PU) composite solar panel frame, jointly developed by Covestro and its partners, provides a new solution for the selection of frame

Get Price

Solar Capped Panel

Assan Panel, as the leading sandwich panel manufacturer, continues to present innovative solutions for sustainable buildings. The brand new Solar Capped Panel has an exclusive

Get Price

BBG''s photovoltaic module with PU frame to be used for large

The Mindelheim-based company has developed a polyurethane frame module for photovoltaic elements that, it claims, helps to increase the energy yield of such solar energy

Get Price

Spray Polyurethane Foam and Photovoltaic Roofing

Spray polyurethane foam and photovoltaic systems are increasingly utilized together as a joint solution for energy savings.

Get Price

Encapsulation of commercial and emerging solar cells with focus

Photovoltaics (PV) is a rapidly growing energy production method, that amounted to around 2.2% of global electricity production in 2019 (Photovoltaics Report - Fraunhofer ISE,

Get Price

Covestro receives polyurethane certificate for solar composite

At the 16th International Photovoltaic Power Generation and Smart Energy Conference & Exhibition 2023 (SNEC) held in Shanghai, Covestro received the polyurethane

Get Price

BRD

🔋☀️ NEW PRODUCT SPOTLIGHT ☀️🔋 Meet the roof that pays for itself: BRD Polyurethane Photovoltaic Roof Panels! It combines thermal insulation, energy efficiency, and

Get Price

polyurethane solar panel frame

According to the national standard "Photovoltaic building integrated system lightning protection technical specification", photovoltaic frame is an insulation component, does not need to be

Get Price

BASF, Worldlight release new PV module frame based on polyurethane

BASF and Worldlight have developed a new PV module frame based on polyurethane. The manufacturers claim that the new solution offers superior insulation and a

Get Price

Dynamic Duo: Optimizing the performance of spray

Spray Polyurethane Foam (SPF) and PV systems are increasingly paired together as a joint solution for energy savings.

Get Price

6 FAQs about [Polyurethane photovoltaic solar panels]

Is polyurethane a good material for solar panels?

As a non-metal material, polyurethane composite frames also reduce the overall price and increase energy efficiency for solar panel module manufacturers over traditional metal aluminum frames. Covestro’s polyurethane composite has superior mechanical properties. Its axial tensile strength is more than 7 times that of a typical aluminum alloy.

What is a polyurethane composite solar panel frame?

The polyurethane composite solar panel frame developed by Covestro and its partners has demonstrated excellent material performance. As a non-metal material, polyurethane composite frames also reduce the overall price and increase energy efficiency for solar panel module manufacturers over traditional metal aluminum frames.

Is BASF's new polyurethane-based PV module frame sustainable?

Aiming towards a more sustainable plastic use in future BASF and Worldlight’s new polyurethane-based PV module frame is the newest addition in the industry. With better efficiency, the new frame offers huge reductions in emissions as compared to aluminum frames.

What materials are used for solar panels?

Aluminum profiles are currently the dominant material for solar PV frames. With the rapid development of solar energy harnessed through PV modules, the amount of aluminum resources used in the production of solar panels is also increasing year by year.

Why do solar PV modules need a frame?

The frame is an important component of solar PV modules, fixing and sealing the modules and backsheet while enhancing the strength of the modules. This strengthening helps to facilitate the transportation and installation of the modules, and performance of the frame directly influences the mounting and service life of the modules.

What are the advantages of Pu composite solar panels?

The volume resistivity of PU composites can reach 1×10 14 Ω-cm. If a solar PV module is packaged with a non-metal frame, the possibility of forming a leakage circuit is greatly reduced, helping reduce occurrences of Potential-Induced Degradation (PID) .The harm of the PID effect results in power attenuation and a decrease in power generation.

More related information

-

New photovoltaic solar panels for sale in Central Asia

New photovoltaic solar panels for sale in Central Asia

-

Canadian Solar Photovoltaic Panels

Canadian Solar Photovoltaic Panels

-

Cyprus has solar photovoltaic panels

Cyprus has solar photovoltaic panels

-

Folding photovoltaic panels for solar power generation

Folding photovoltaic panels for solar power generation

-

Solar energy prices for photovoltaic panels in Togo

Solar energy prices for photovoltaic panels in Togo

-

Install solar photovoltaic panels in family homes

Install solar photovoltaic panels in family homes

-

East Timor solar panels photovoltaic panels

East Timor solar panels photovoltaic panels

-

Selling solar photovoltaic panels

Selling solar photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

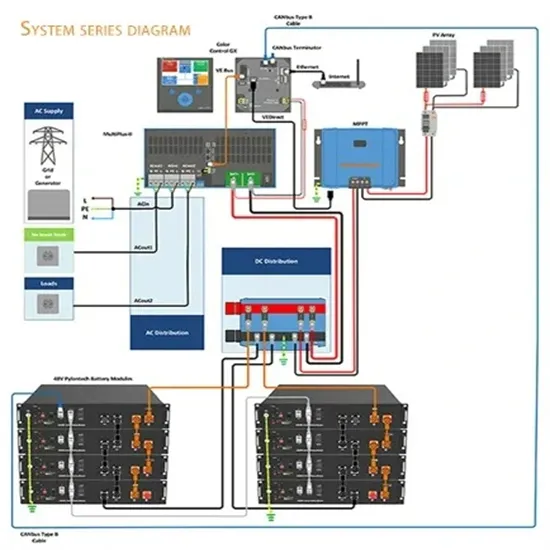

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.