PV statistics and long-term degradation

Explore PV energy systems statistics, losses, and long-term degradation data to optimize performance and enhance decision-making for your solar projects.

Get Price

Losses in Solar Panel Systems

Modern PV inverters reduce overall PV generation by about 4% through the process of inversion from direct current to alternating current. Total Solar

Get Price

12 types of Losses in Solar PV system

Inverter loss is the DC to AC conversion, this loss occurs when the inverter converts DC power to AC power. This loss depends on Inverter efficiency which can be described as how well a

Get Price

Effect of Reactive Power on Photovoltaic Inverter Reliability

In order to achieve this, a detailed electrothermal model of the PV inverter will be developed along with their controllers capable of providing voltage support through reactive power. An in-house

Get Price

Quantifying the impact of inverter clipping on photovoltaic

It is commonly assumed that cleaning photovoltaic (PV) modules is unnecessary when the inverter is undersized because clipping will sufficiently mask the soiling losses.

Get Price

Understanding RatedPower''s losses and how to

Therefore, the PV module losses come first, followed by those of the string, inverter, transformer, substation and grid. Once the design is

Get Price

Effects of Wide Bandgap Devices on the Inverter

With power demands continuously growing, the penetration of renewable energy resources, particularly solar photovoltaic (PV) systems,

Get Price

Inverter clipping: How to maximize solar project value

Inverter clipping, or "inverter saturation," occurs when DC power from a PV array exceeds an inverter''s maximum input rating. The inverter may

Get Price

PV system losses

A detailed breakdown of your PV system losses is provided on the PV system losses page. For better data analysis, the page is further categorized into yearly and monthly

Get Price

12 types of Losses in Solar PV system

Inverter loss is the DC to AC conversion, this loss occurs when the inverter converts DC power to AC power. This loss depends on Inverter efficiency

Get Price

Loss Analysis of a 100kW PV Inverter

In this paper, the losses of PV inverter system are first analyzed. A compromise had been made between calculation precision and complexity and, thus, practical methods are selected to

Get Price

10 Solar PV System Losses – How To Calculate Solar Panel

PV system losses have a substantial impact on the overall efficiency and output power of solar panel arrays. Good solar design takes into account 10 main PV losses, while best design and

Get Price

Top Solar PV Losses: Impacts on Efficiency and Tips to Control

Solution: To minimize irradiance-related losses, optimize panel orientation and tilt for maximum sunlight exposure, use high-efficiency modules with good low-light performance, and include

Get Price

Understanding RatedPower''s losses and how to reduce them

Therefore, the PV module losses come first, followed by those of the string, inverter, transformer, substation and grid. Once the design is simulated, the losses can be

Get Price

Understanding PV System Losses, Part 4: Solar Panel Tilt, Solar

Looking to understand PV system losses in detail? Part 4 examines Environmental Conditions, Inverter Losses & Clipping, and more.

Get Price

Understanding RatedPower''s losses and how to reduce them

This loss occurs in the cables connecting the photovoltaic module strings to the string boxes and inverters (or directly to the inverters if the plant is designed using a DC bus

Get Price

Guide to understanding solar production losses

When investing in solar, maximizing production is a common goal. Aurora Solar, a leading solar design and performance software provider, released a guide for understanding

Get Price

Physical models used > Grid inverter > Inverter Operating Limits

The inverter input electronics assumes the function of choosing the operating point on the I/V curve of the PV array. In normal conditions it will choose the maximum power point (MPPT

Get Price

Benchmarking of capacitor power loss calculation methods for

Therefore, this paper benchmarked four capacitor power loss calculation methods and compared their impact on the wear-out failure prediction of PV inverters. Method 1

Get Price

Analysis of Power Loss in Transformerless Grid Connected PV Inverter

Efficiency is becoming increasingly important in grid connected photovoltaic inverter design. Transformer in grid connected inverter system is removed to improve the efficiency of

Get Price

Photovoltaic Inverter Reliability Assessment

To evaluate the impacts of thermal cycling, a detailed linearized model of the PV inverter is developed along with controllers. This research also develops models and methods to

Get Price

Best practices for photovoltaic performance loss rate

The performance loss rate (PLR) is a vital parameter for the time-dependent assessment of photovoltaic (PV) system performance and health

Get Price

Top Solar PV Losses: Impacts on Efficiency and Tips

Solution: To minimize irradiance-related losses, optimize panel orientation and tilt for maximum sunlight exposure, use high-efficiency modules with good low

Get Price

Guide to understanding solar production losses

When investing in solar, maximizing production is a common goal. Aurora Solar, a leading solar design and performance software provider,

Get Price

Understanding Solar Inverter Losses Efficiently

Solar inverter efficiency is a critical factor in maximizing the energy efficiency of a PV system. At [Brand Name], we understand the significance of

Get Price

How to Reduce DC to AC Inverter Losses & Boost

Understanding inverter power loss, selecting efficient inverters and adopting appropriate energy saving measures to improve the efficiency of

Get Price

Inverter Losses

InvLoss Global inverter loss - This is the sum of all inverter losses. IL Oper Inverter Loss during operation (efficiency curve) - The inefficiency loss, computed according to the

Get Price

6 FAQs about [PV inverter power loss]

What are the losses of a PV solar panel?

We can divide the losses of a PV solar into three main categories: Front-face and back-face losses reflect the issues related to the ability of panels to capture sunlight. However, the electrical losses depict the power conversion problems.

How does power loss affect the performance of a photovoltaic system?

The performance of a photovoltaic (PV) system is highly affected by different types of power losses which are incurred by electrical equipment or altering weather conditions. In this context, an accurate analysis of power losses for a PV system is of significant importance.

What causes energy production loss in solar PV systems?

In today’s article, the latest installment of Aurora’s PV System Losses Series –in which we explain specific causes of energy production loss in solar PV systems–we explore losses from tilt and orientation, incident angle modifier, environmental conditions, and inverter clipping.

Is inverter power limitation loss zero?

Hence, the inverter power limitation loss is not zero. Since this type of loss was zero for the first PV system, no prediction model was built for that. Moreover, the low irradiance, spectral, and reflection losses are about 1% which is lower compared to the first PV system. MPPT losses are again assumed to be 1.5%.

Why do inverters lose power?

DC Losses: This happens due to resistance in cables before inverter conversion. Inverter (Power Limitation) Losses: Occur when generated power exceeds inverter capacity. Inverter (DC/AC Conversion) Losses: Result from inefficiencies during DC to AC conversion.

What is the Ultimate Guide to PV system losses?

Aurora Solar’s Ultimate Guide to PV System Losses includes basic solar performance concepts like the effect of tilt, orientation, and shade on production metrics. The guide walks through how mismatched equipment can cause losses and surveys the effects of incident angle modifiers, and module nameplate rating losses. Tilt and orientation

More related information

-

PV panel power and inverter configuration

PV panel power and inverter configuration

-

PV inverter adjusts power output time

PV inverter adjusts power output time

-

PV inverter power specifications

PV inverter power specifications

-

PV inverter output power quality

PV inverter output power quality

-

The greater the inverter power the greater the loss

The greater the inverter power the greater the loss

-

Is there any power loss in the inverter

Is there any power loss in the inverter

-

Yaounde PV energy storage 15kw inverter power supply

Yaounde PV energy storage 15kw inverter power supply

-

Yemen Dual Power PV Inverter

Yemen Dual Power PV Inverter

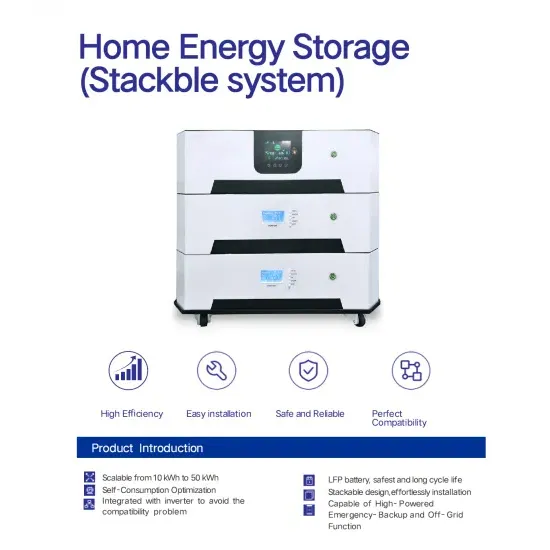

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.