Mitigation of Corrosion in Solar Panels with Solar Panel Materials

Corrosion in solar panels represents a significant problem in the solar energy industry, caused by exposure to aggressive environmental conditions. Corrosion on PV

Get Price

Bird-Proof Your Solar Panels: Why It Matters & Effective Strategies

INDEX: Why bird-proof solar panels? The impact of bird''s behavior on solar panels Quantifying the impact of bird droppings on solar panels Mitigation strategies Solar Panel''s

Get Price

How to prevent corrosion of solar panels | NenPower

By prioritizing meticulous inspections and ongoing maintenance, solar panel systems can be safeguarded against the detrimental effects of corrosion, guaranteeing a more

Get Price

How Galvanized Steel Prevents Rust on Solar Mounting Systems

Preventing solar panel rust should be the first priority when choosing the style and make-up of the system''s components. Galvanized steel continues to outperform the other

Get Price

Corrosion Alert: Why Solar On Galvanised Roofs Is Bad News

When different metals are combined, and an electrolyte is added, they create a battery. Given some time, the less noble metal can corrode to the point of disappearing

Get Price

Galvanic Corrosion Considerations for PV Arrays

For a PV installation, the long-term effects of corrosion can range from unsightly finishes to racking or fastener failure. The more dissimilar the

Get Price

How To Protect Solar Panels From Corrosion? What Are The

Prolonged exposure to moisture not only affects the performance of solar panels but can also cause corrosion. Therefore, when installing solar panels, the design and material

Get Price

Galvanic Corrosion and Protection in Solar PV Installations

The life of a solar PV system may be seriously effected by galvanic corrosion. The type of metal and the atmospheric conditions such as moisture and chlorides can cause serious structural

Get Price

How To Protect Solar Panels From Corrosion? What

Prolonged exposure to moisture not only affects the performance of solar panels but can also cause corrosion. Therefore, when installing solar

Get Price

Corrosion Rate and Protective Design Safety Thresholds for Steel

Protective coatings and proper steel thickness tailored to site conditions help prevent corrosion and maintain structural safety. Regular inspections and maintenance catch

Get Price

How Galvanized Steel Prevents Rust on Solar Mounting Systems

For superior solar panel corrosion protection, galvanized materials are the best choice wherever possible. The best sizes and weights to choose when assembling your solar

Get Price

Everything You Need to Know About Solar Conduit

It naturally resists corrosion and works well outdoors. The trade-off? It''s softer than steel, so it can get dented more easily if something hits it hard. So, which

Get Price

How to Prevent Corrosion in Solar Panel Systems

Not only are they highly resistant to corrosion, but they''re also more likely to withstand natural disasters. This attribute can significantly increase your

Get Price

Common Solar Panel Defects

Common solar panel defects like discoloration, delamination, diode failure, and damage can reduce output—learn how to prevent and fix them.

Get Price

Guide to good practice – steel roofing and photovoltaic/solar

Introduction When installing photovoltaic (PV) / solar panels to roofing made from COLORBOND® prepainted steel or ZINCALUME® aluminium/ zinc/magnesium alloy-coated steel, the following

Get Price

How to prevent corrosion of solar panels | NenPower

By prioritizing meticulous inspections and ongoing maintenance, solar panel systems can be safeguarded against the detrimental effects of

Get Price

5 Proactive Ways to Protect Your Solar Setup from Corrosion

This article will explore proactive ways that you can protect your solar investment by slowing down and even preventing corrosion, enabling your solar panels to keep on giving

Get Price

MC4 Solar Panel Connectors | Best Practices

MC4 Solar Panel Connectors - Discover the best practices for connecting and disconnecting MC4 connectors, troubleshooting common issues, and

Get Price

Does Salt Water Affect Solar Panels? A Must-Read

Solar panels near the ocean can get damaged by saltwater corrosion and degradation from the sea. If not protected by things like anodized aluminum,

Get Price

How To Install Solar Panels Step By Step: A Complete DIY Guide

Learn how to install solar panels yourself with this detailed, step-by-step guide. Discover tools, permits, common mistakes, and pro tips for a smooth DIY solar setup.

Get Price

Managing and Mitigating Solar PV Corrosion

Introducing solar system components into a severely corrosive environment can accelerate corrosion processes, leading to severe damage, performance loss, and safety issues.

Get Price

Galvanic Corrosion Considerations for PV Arrays

For a PV installation, the long-term effects of corrosion can range from unsightly finishes to racking or fastener failure. The more dissimilar the metals, as reflected by their

Get Price

How To Seal Between Solar Panels (Do This!)

The installation process of solar panels cannot be complete without sealing between them. Unfortunately, most people forget this vital detail, and

Get Price

How to Prevent Corrosion in Solar Panel Systems

Not only are they highly resistant to corrosion, but they''re also more likely to withstand natural disasters. This attribute can significantly increase your system''s lifespan and prevent downtime.

Get Price

Mitigation of Corrosion in Solar Panels with Solar

Corrosion in solar panels represents a significant problem in the solar energy industry, caused by exposure to aggressive environmental

Get Price

Are Solar Panels Waterproof? Exploring Answers

So, are solar panels waterproof? Can solar panels be installed in the rain? In this article, we will delve into the intricacies of solar panel

Get Price

Solar Panel Installation: How to Install Solar Step by

Learn step-by-step instructions for DIY solar panel installation, from selecting the right equipment to setting up your system effectively and safely.

Get Price

Understanding Solar Panel Lifespan: Factors Affecting

Discover the key factors influencing life expectancy of solar panels. Learn how material quality, installation, environmental conditions, maintenance,

Get Price

Galvanic Corrosion and Protection in Solar PV

The life of a solar PV system may be seriously effected by galvanic corrosion. The type of metal and the atmospheric conditions such as moisture and chlorides

Get Price

Solar Panels on Metal Roof (Advantages

Solar panels are typically mounted on pitched roofs with shingles, although there are other mounting positions like the ground, pole, and metal

Get Price

6 FAQs about [Can installing photovoltaic panels prevent corrosion ]

What is galvanic corrosion in solar PV?

The life of a solar PV system may be seriously effected by galvanic corrosion. The type of metal and the atmospheric conditions such as moisture and chlorides can cause serious structural failures in racking and mounting components. Galvanic Corrosion and Protection in Solar PV Installations | Greentech Renewables Skip to main content menu

Can solar PV racking corrosion occur?

The metals in solar PV racking and mounting systems can be faced with corrosion if wrong metals are used together. The life of a solar PV system is 25 years, therefore system installers must target a similar life span for the racking materials. How does galvanic corrosion occur?

How do I protect my solar panels from galvanic corrosion?

For example, when installing solar panels onto mounting rails, some thought should go into preventing galvanic corrosion between dissimilar metals. A good installer will use an anti-seize compound on the fasteners or an anti-corrosion coating designed for dissimilar metals.

Why is corrosion a problem in solar panels?

Author: Ph.D. Yolanda Reyes, March 24, 2024. Corrosion in solar panels represents a significant problem in the solar energy industry, caused by exposure to aggressive environmental conditions. Corrosion in photovoltaic modules will lead to a reduction in module power output and affect the entire output of your system.

Can solar panels be corroded?

Representative image of corrosion in solar modules1. Corrosion can also reduce the lifetime of solar panels, resulting in additional maintenance and replacement costs. Likewise, repair or replacement of corroded components can be costly and affect the long-term profitability of solar projects.

How to prevent corrosion in PV systems?

The installer has to be careful in choosing the right material. We usually suggest using anodized components to prevent corrosion for the PV systems that are near ocean (salt conditions). Below is a list of best practices for corrosion prevention: Use one material to fabricate electrically isolated systems or components where practical.

More related information

-

Photovoltaic power station installing solar panels

Photovoltaic power station installing solar panels

-

Danish companies installing solar photovoltaic panels

Danish companies installing solar photovoltaic panels

-

The benefits of Huawei installing photovoltaic solar panels

The benefits of Huawei installing photovoltaic solar panels

-

Cost of installing photovoltaic panels on rooftops in Portugal

Cost of installing photovoltaic panels on rooftops in Portugal

-

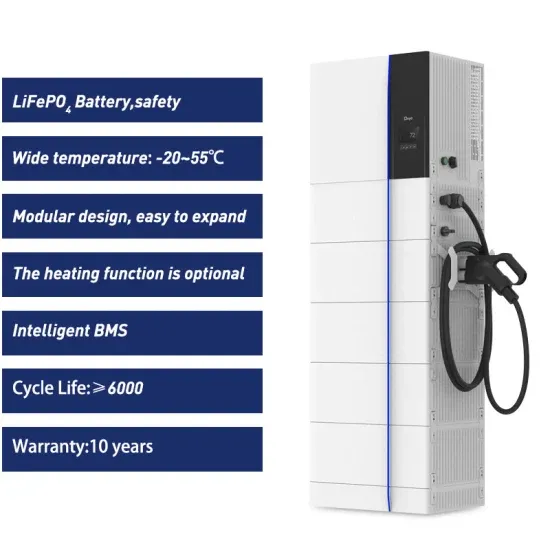

Which type of battery is more durable when installing photovoltaic panels

Which type of battery is more durable when installing photovoltaic panels

-

Requirements for installing photovoltaic panels in container houses

Requirements for installing photovoltaic panels in container houses

-

The price of installing a set of photovoltaic panels

The price of installing a set of photovoltaic panels

-

Asia s new solar photovoltaic panels

Asia s new solar photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

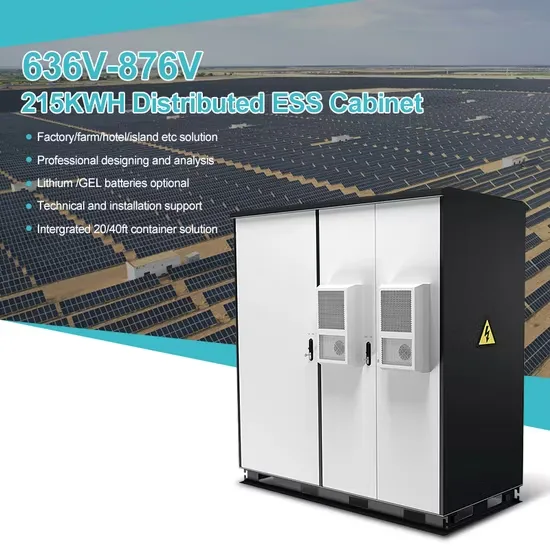

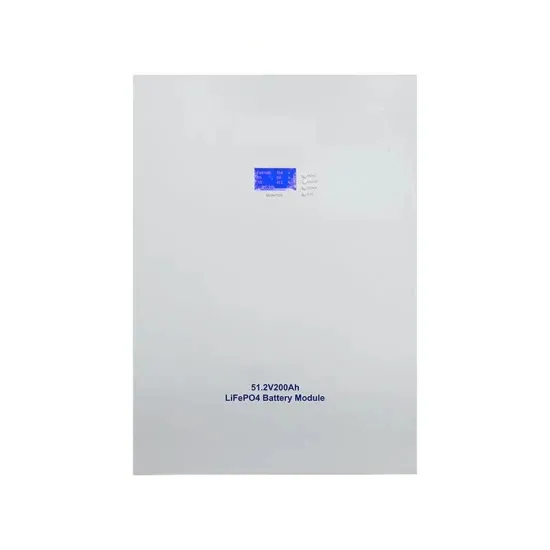

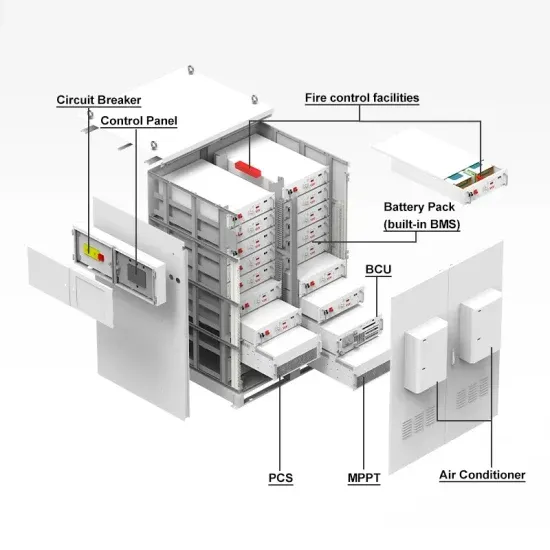

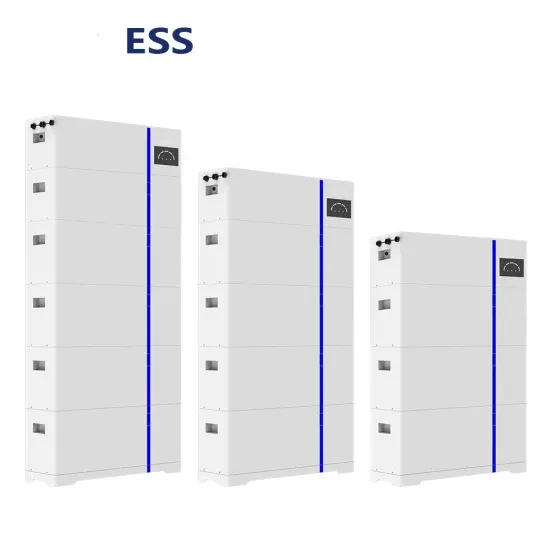

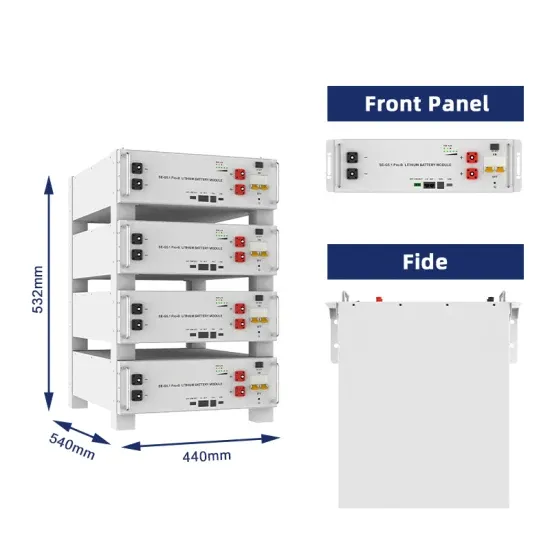

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

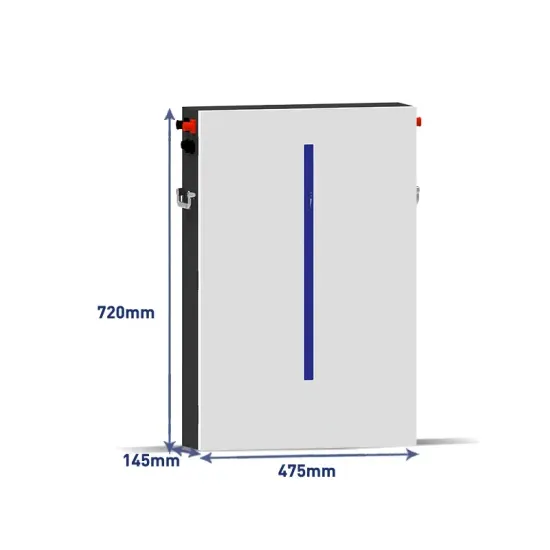

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.