Design and analysis of a flywheel energy storage system fed by

Therefore, increasing the angular velocity of the flywheel is more effective than increasing the mass of the flywheel. Flywheels are generally used as a storage device in the

Get Price

How does flywheel energy storage work?

At its core, flywheel energy storage operates on the principle of kinetic energy. A flywheel is essentially a heavy rotating mass, usually made of high - strength materials like

Get Price

Flywheel Energy Storage

Direct current (DC) system flywheel energy storage technology can be used as a substitute for batteries for providing backup power to an uninterruptible power supply (UPS) system.

Get Price

Flywheels in renewable energy Systems: An analysis of their role

This paper presents an analytical review of the use of flywheel energy storage systems (FESSs) for the integration of intermittent renewable energy sources into electrical

Get Price

flywheel energy storage should be ac or dc

Flywheel energy storage AC/AC converters (transformers) or two serial AC/DC–DC/AC converters, that is, rectifier–inverter, are the most commonly used circuits in FESS and can be

Get Price

Flywheel energy storage

The main conclusion of the literature review was that FESS is a promising energy storage solution; up to multiple megawatt scale. However, few large-scale installations have so far

Get Price

Flywheel Energy Storage

Advances in power electronics, magnetic bearings, and flywheel materials coupled with innovative integration of components have resulted in direct current (DC) flywheel energy storage

Get Price

A Review of Flywheel Energy Storage System Technologies

A bidirectional converter adopts either a DC-AC or a DC-DC-AC structure if the input/output of the FESS is a DC bus. In the case of AC input/output, a bidirectional converter

Get Price

A Review of Flywheel Energy Storage System

One energy storage technology now arousing great interest is the flywheel energy storage systems (FESS), since this technology can offer many advantages as

Get Price

(PDF) Implementation and Control of an AC/DC/AC

An all-electric driveline based on a double wound flywheel, connected in series between main energy storage and a wheel motor, is presented. The flywheel works as a

Get Price

A Review of Flywheel Energy Storage System

Energy storage systems (ESS) provide a means for improving the efficiency of electrical systems when there are imbalances between supply and demand.

Get Price

Overview of Control System Topology of Flywheel

Abstract. Flywheel energy storage system (FESS) technologies play an important role in power quality improvement. The demand for FESS

Get Price

Flywheel energy storage

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy.

Get Price

The Flywheel Energy Storage System: A Conceptual Study,

Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are composed of various

Get Price

A comprehensive review of Flywheel Energy Storage System

Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Get Price

Technology: Flywheel Energy Storage

Each FESS module has a power electronics module which allows its AC motor-generator to interface with a DC bus that is common to several FESS modules. Power and energy can be

Get Price

The Flywheel Energy Storage System: A Conceptual Study,

Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and reliability of the

Get Price

MECHANICAL DESIGN AND ANALYSIS OF FREE POWER

INTRODUCTION The energy which has no cost is called free energy the concept of project is explore the possiblities of combinig three units.i.e. torsional vibration, flywheel and mechanical

Get Price

The Status and Future of Flywheel Energy Storage

The MG must be brush-less, with AC current being generated by the inverter for motoring, and then AC current is converted back to DC in generator mode. In most cases, the MG is

Get Price

The high-speed flywheel energy storage system 11. ac/dc

Figure 1 The High-speed Flywheel Energy Storage System 11. AC/DC converter A unity input power factor control of a three-phase step-up converter is feasible in the rotating co-ordinate

Get Price

Flywheel Energy Storage System

The entire flywheel energy storage system realizes the input, storage, and output processes of electrical energy. The flywheel battery system includes a motor, which operates in the form of

Get Price

A review of control strategies for flywheel energy storage system

The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Get Price

Flywheel Energy Storage

Flywheel energy storage stores kinetic energy by spinning a rotor at high speeds, offering rapid energy release, enhancing grid stability, supporting renewables,

Get Price

The Status and Future of Flywheel Energy Storage

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Get Price

A review of flywheel energy storage systems: state of the art and

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get Price

Start It Up: Flywheel Energy Storage Efficiency

By constructing an off-grid photovoltaic (PV) system in which the power of a single-crystalline array was stored in a rechargeable battery and a flywheel, the mechanical flywheel energy

Get Price

A review of flywheel energy storage systems: state of the art and

Highlights • A review of the recent development in flywheel energy storage technologies, both in academia and industry. • Focuses on the systems that have been

Get Price

A review of control strategies for flywheel energy storage system

A comprehensive review of control strategies of flywheel energy storage system is presented.

Get Price

A review of flywheel energy storage systems: state of the art

Primary candidates for large-deployment capable, scalable solutions can be narrowed down to three: Li-ion batteries, supercapacitors, and flywheels. The lithium-ion

Get Price

6 FAQs about [Flywheel energy storage should be AC or DC]

What is a flywheel energy storage system (fess)?

One energy storage technology now arousing great interest is the flywheel energy storage systems (FESS), since this technology can offer many advantages as an energy storage solution over the alternatives.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Is a flywheel a good option for energy storage?

However, due to the recent improvements in materials, magnetic bearings, power electronics, and the introduction of high speed electric machines, FESS have been established as a solid option for energy storage applications [7, 8, 9, 26, 27]. A flywheel stores energy that is based on the rotating mass principle.

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Can a matrix converter-fed flywheel energy storage system be predictive?

A case study of model predictive control of matrix converter-fed flywheel energy storage system is implemented. Flywheel energy storage system comes around as a promising and competitive solution. Potential future research work is suggested. Energy storage technology is becoming indispensable in the energy and power sector.

More related information

-

Flywheel energy storage DC

Flywheel energy storage DC

-

Djibouti Flywheel Energy Storage Project

Djibouti Flywheel Energy Storage Project

-

What scenarios are flywheel energy storage suitable for

What scenarios are flywheel energy storage suitable for

-

Flywheel energy storage installation in the Bahamas

Flywheel energy storage installation in the Bahamas

-

Maldives flywheel energy storage products

Maldives flywheel energy storage products

-

Flywheel Energy Storage Plant in Tanzania

Flywheel Energy Storage Plant in Tanzania

-

Croatia Flywheel Energy Storage Project

Croatia Flywheel Energy Storage Project

-

What is flywheel energy storage wind power

What is flywheel energy storage wind power

Commercial & Industrial Solar Storage Market Growth

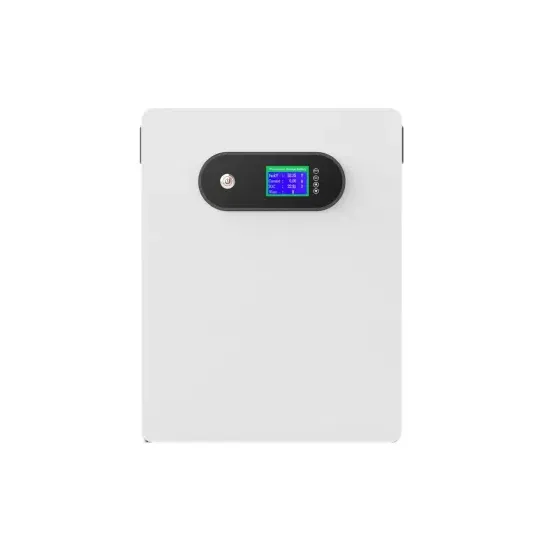

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.