IEC and European Inverter Standards, Baltimore High

In Germany installation costs for a grid-connected system are in the range of 4.200 to 5.000 € / kWp installed System prices in the US are in the order of 6.500 to 9.000 US$ / kWp installed

Get Price

Lightning protection for Telecommunication Stations

Lightning protection (strikes with indirect effects) for telecommunication stations by lightning arresters, is applicable for all electrical networks. It is also compulsory to provide protection

Get Price

Surge Protection for Petrol Stations

Lightning and surge protection are crucial for petrol stations, fuel stations, gas stations to manage fuel and prevent explosions.

Get Price

Installation and safety requirements for photovoltaic

6.4.1 When installing a grid connect battery backup system, the installation shall be performed by an accredited installer with a grid connected battery endorsement.

Get Price

Lightning and Surge Protection for Communication Station

Install lightning rods, grounding, surge protectors, shielding, and follow standards for effective communication station protection.

Get Price

12

This technical specification covers the technical requirements of the design, supply at site, installation and testing of Substation earthing and lightning protection system complete with all

Get Price

Tower and Base Station Antenna Grounding

The lightning protector is connected to a ground or ground plate, which is bonded to the electrical system ground. Inside your house, all of your devices (radios, power supplies,

Get Price

ITU-T Rec. K.112 (07/2019) Lightning protection, earthing

The purpose of this Recommendation is to give detailed guidance on protection procedures, so that an engineer who is not a lightning protection expert can accomplish the design of the

Get Price

Basics of Lightning Protection for Communication Towers

For lightning protection best resources are Polyphasers book the ARRL Handbook along with the book "Grounding and Bonding for the Radio Amateur". The ARRL Handbook contains good

Get Price

Lightning Protection and Grounding

This section describes the lightning protection and grounding requirements. Ensure that the equipment room meets the requirements because lightning is one of the major factors that

Get Price

Installing Lightning Protection

The purpose of this document is to detail the proper installation procedures for many of the items typically used for lightning protection in and around an Amateur Radio Station.

Get Price

LPI-175 / 2023 Edition

Lightning Protection System – A complete system of strike termination devices, main conductors (including conductive structural members), grounding electrodes, bonding or interconnecting

Get Price

LMrev2005_Final.book

Chapter 2 of this manual specifies requirements for surge and transient protection, lightning protection, earth electrode system (EES), electronic multipoint ground system (MPG),

Get Price

TECHNICAL GUIDELINES FOR THE INSTALLATION AND

The Weather Monitoring Station and PV Monitoring System shall be provided, installed and maintained by the FIAH for the entire duration of the Feed in Approval.

Get Price

FAQ

When a lightning protection grounding network is in place, the strike is intercepted and directed to ground without impact to the structure, occupants or contents.

Get Price

LMrev2005_Final.book

All contractors performing work at an NWS facility involving installation of a lightning protection system shall meet the requirements of this manual, if it is part of the contract statement of work

Get Price

LIGHTNING PROTECTION AND GROUNDING

Metal Oxide Varistor (MOV) arresters are normally used for protection of overhead distribution circuits or equipment where conditions warrant (e.g. high ground resistance or retrofitting

Get Price

Surge Protection for Cell Sites

A thorough lightning and surge protection approach provides optimal safety for people and high availability systems. LSP designs specialized AC and DC Surge Protection

Get Price

Technical reference Lightning protection to NFPA & UL

Lightning protection to NFPA & UL standards Within certain markets installation of an LPS, including component selection, is governed by American NFPA and UL standards rather than

Get Price

Technical Requirements For Lightning Protection And Grounding

The grid size of the lightning protection net should meet the requirements, and it should be welded and connected with the lightning protection belt one by one.

Get Price

NEC Standards & Lightning Protection Guidelines | ES Grounding

This tried and true standard issued by the same group that writes the National Electric Code (The NFPA), provides an excellent guideline for installing a straightforward one-size-fits-all lightning

Get Price

Installing Lightning Protection

This tried and true standard issued by the same group that writes the National Electric Code (The NFPA), provides an excellent guideline for installing a straightforward one-size-fits-all lightning

Get Price

Lightning Protection System & Earthing for

A proper lightning protection system in electrical substations provides a low resistance path to ensure the correct operation of protection

Get Price

Grounding and Lightning Protection for Substations

This is about requirements for lightning protection for buildings, Substation Earthing Layout, lightning protection system, transformer lightning protection, grounding and lightning protection

Get Price

6 FAQs about [Installation requirements for grid-connected lightning protection boxes for communication base station inverters]

How many connections should a ground bar have to a lightning protection system?

A ground bar designed for interconnection of building grounded systems shall have one connection to the lightning protection system. A continuous metal water pipe system designed for interconnection of building grounded systems shall have one connection to the lightning protection system.

How should a lightning protection system be maintained?

An inspection and maintenance procedure is recommended, and may be conducted by the system installer, an authority. Keeping the lightning protection system up to date with current standards ensures the greatest level of safety. When a lightning protection system is upgraded, as-built drawings should be revised to document modifications.

Can lightning protection system components be concealed in building construction?

176) Lightning protection system components may be concealed in building construction. A lightning protection system is a low resistance continuous metallic path designed for the purpose of transferring lightning from the top of a structure into the earth.

Where should earthing and lightning protection systems be installed?

The earthing and lightning protection systems are to be installed indoors and outdoors in electrically exposed locations, less than 1,000 metres above sea-level. The maximum wind (gust) velocity is 50 metres per second. The humidity is high and the atmosphere is often salt-laden.

What are the requirements for earthing & lightning protection systems?

Temperature shall be in degrees Celsius. Electrical energy shall be in kWh and gas and fluid pressure shall be expressed in MPa. The earthing and lightning protection systems are to be installed indoors and outdoors in electrically exposed locations, less than 1,000 metres above sea-level. The maximum wind (gust) velocity is 50 metres per second.

Does a substation need a lightning protection system?

This risk assessment shall determine whether a more onerous lightning protection system (LPS) is required at the substation. The design of the LPS shall based on the methods contained in IEC 62305 Protection against lightning, Part 3, Physical damage to structures and life hazard (i.e. the protection angle and rolling sphere methods).

More related information

-

Are the grid-connected installation requirements for French communication base station inverters high

Are the grid-connected installation requirements for French communication base station inverters high

-

Communication base station inverter grid-connected installation requirements

Communication base station inverter grid-connected installation requirements

-

Requirements for outdoor grid-connected communication base station inverters

Requirements for outdoor grid-connected communication base station inverters

-

Madagascar Communication Base Station Inverter Grid-Connected Installation Regulations

Madagascar Communication Base Station Inverter Grid-Connected Installation Regulations

-

Mobile communication green base station lightning protection

Mobile communication green base station lightning protection

-

Mobile communication green base station lightning protection price

Mobile communication green base station lightning protection price

-

Qatar communication base station flow battery station planning requirements

Qatar communication base station flow battery station planning requirements

-

Huawei Communication Base Station Inverter Grid-Connected Equipment Company

Huawei Communication Base Station Inverter Grid-Connected Equipment Company

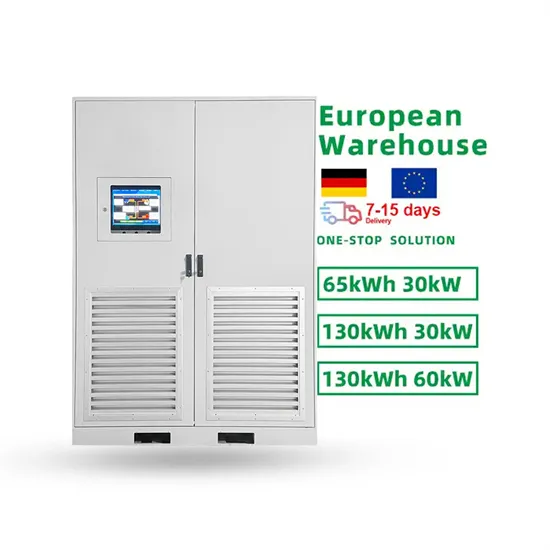

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.