What Size Inverter Do I Need

What size inverter do you need? This guide covers wattage calculations, surge power, and key factors to help you choose the right

Get Price

Wire Size For 220V (With 20A, 30A, 40A, 50A, 60A

The wattage of each appliance will determine the wire gauge you should use. Distance VS 220V – How Far Can You Run The Wire? The best gauge is the

Get Price

What Size Generator Is Needed to Run a Well Pump: A

Choosing the right generator size to run a well pump is crucial for ensuring consistent water supply during power outages. The generator must supply adequate power to

Get Price

Selecting the Proper Inverter / Frequency Converter for your

For example, if you have a pump which runs off of 120 VAC and has a Locked Rotor Current of 10 Amps, you would need an inverter of at least 1200 VA to run the pump (120 VAC x 10A = 1200

Get Price

What inverter size would run this well pump

I''m hoping to spec my first inverter large enough to power my deep well pump. Here is my confusion. and the label says... Why the 2 voltages? Am I assuming correctly that

Get Price

Inverter Size Chat: What Size Inverter Do I Need?

That''s why I''ve put together a handy inverter size chart in order for you to quickly find out what size inverter is best for your needs. We''ll start by going through the basic considerations, use

Get Price

The Only Inverter Size Chart You''ll Ever Need

We have created a comprehensive inverter size chart to help you select the correct inverter to power your appliances.

Get Price

What Size Inverter Do I Need

What size inverter do you need? This guide covers wattage calculations, surge power, and key factors to help you choose the right inverter size.

Get Price

What Inverter Size for Well Pump to Use?

Here is a guide for the minimum inverter and well pump combination. In the figures above you will notice that the inverter size is not always double that of the running watts. The rule of thumb is

Get Price

Water Pump and Inverter Compatibility: The Ultimate Guide

What To Know The answer to this question depends on the type of water pump and the characteristics of the inverter. Using an inverter with these pumps can lead to

Get Price

Inverter Size Calculator

The Inverter Size Calculator is a digital tool that allows you to determine the correct inverter size needed for a specific total wattage load, considering factors like safety margins and inverter

Get Price

How To Choose A Well Pump Breaker Size: A Full Guide

How do you select a good well pump breaker size? Circuit breakers prevent extra amps from running through your pump. So you''ve to

Get Price

Sizing the Right Inverter for 100ah Battery

In this guide, I will walk you through the process of sizing the right inverter for a 100ah battery along with an inverter size chart.

Get Price

What Size Inverter Do I Need To Run A Pump?

The size of the inverter should be equal to or slightly larger than the calculated power requirements of the pump. However, it is advisable to

Get Price

50 hp Horizontal Centrifugal Pump | inverter

Horizontal centrifugal pump has a 50 hp motor power, optional input voltage 3 phase AC 220V/230V/240V, 380V/400V/415V to 440V/460V/480V, and

Get Price

What Size Inverter Do I Need?

Finding the proper inverter size for your needs is as simple as adding together the necessary wattages of the items that you''re looking to power.

Get Price

What Size Inverter Do I Need To Run A Pump?

The size of the inverter should be equal to or slightly larger than the calculated power requirements of the pump. However, it is advisable to leave some headroom when

Get Price

What Size Inverter do I Need? [with Examples]

The size of the inverter that you need greatly depends on the anticipated usage. All the devices that you plan to run at the same time have to be added and then pick the inverter closest for

Get Price

Inverter Size Chat: What Size Inverter Do I Need?

That''s why I''ve put together a handy inverter size chart in order for you to quickly find out what size inverter is best for your needs. We''ll start by going through

Get Price

What size generator do I need to run my submersible well pump?

The amperage rating of the pump motor times the voltage would be the wattage that the pump needs once it has started up. But an electric motor needs an initial surge of power to

Get Price

What Size Inverter do I Need? [with Examples]

The size of the inverter that you need greatly depends on the anticipated usage. All the devices that you plan to run at the same time have to be added and

Get Price

Installing Electrical Wiring for a 220V Well Pump

Learn how to wire a 220v well pump for efficient operation and proper installation to ensure a reliable water supply.

Get Price

What Size Inverter Do I Need

To answer what size inverter do I need, you must know nominal load, surge power and continuous load of your appliances. After compensating the

Get Price

Adding a 240V inverter for well pump

The pump only runs 4 or 5 times a day to refill our pressure tank and the well is only 80 ft deep and about 30 or 40 feet from the house. Again, this is for emergency use only,

Get Price

What Inverter Size Do I Need to Run an Air Compressor?

An air compressor requires plenty of power to run. Your inverter must be the right size to keep your air compressor and tools running.

Get Price

System size for 220 volt well pump.

A good low 6-7kw frequency inverter should do the job as the should be able to surge to double their rating for plenty long enough to start the pump. To figure out battery and

Get Price

How to size an inverter that can run your air conditioner?

In this article, I''ll explain in detail the main specifications to look at when shopping for an inverter that can run your air conditioner. I get

Get Price

6 FAQs about [What size inverter should I use for a 220w circulation pump ]

How much inverter do I need to run a pump?

For example, if you have a pump which runs off of 120 VAC and has a Locked Rotor Current of 10 Amps, you would need an inverter of at least 1200 VA to run the pump (120 VAC x 10A = 1200 VA). It is not recommended to start two motor loads simultaneously unless a very large capacity inverter is being used.

How do I choose the right inverter size for my pump?

When selecting an inverter size for the pump, it is important to choose one that can handle the startup power as well as the running power demanded by the pump. Inverters come in various sizes, typically measured in watts (W) or kilowatts (kW).

What size inverter do I Need?

To determine the appropriate size of the inverter needed to run a pump, it is necessary to calculate the power requirements of the pump. The power requirements can be calculated using the following formula: Power (Watts) = Voltage (Volts) x Current (Amps) First, you need to identify the voltage and current requirements of the pump.

Can a 500W inverter run a well pump?

As long as the inverter can handle the surge watts, you should be able to run the pump without trouble. Of course the rest of your solar system must be of sufficient size too. Does this mean you should get a 500W inverter? No, because the well pump still needs 3000 watts approximately during startup.

How to size a 1500 watt power inverter?

A rule-of-thumb for sizing your 1500-watt power inverter is to combine the wattage of all the devices you are planning to use at the same time (don’t forget basic necessities, like lights) and give yourself 20% headroom.

How to calculate inverter size?

Using the Inverter Size Calculator is quick and easy. You’ll need three inputs: Total Wattage (W): This is the total power consumption of all the appliances or devices you plan to run through the inverter. Safety Factor: A multiplier to ensure some buffer above your actual power requirement. Typically ranges from 1.1 to 1.5.

More related information

-

What size inverter should I use for a 1 5kw water pump inverter

What size inverter should I use for a 1 5kw water pump inverter

-

What size solar panel should I use with a water pump inverter

What size solar panel should I use with a water pump inverter

-

What size inverter should I use with a 48w battery

What size inverter should I use with a 48w battery

-

What size inverter should I use with a 240A lithium battery

What size inverter should I use with a 240A lithium battery

-

What size inverter should I use for a 60w solar panel

What size inverter should I use for a 60w solar panel

-

What size inverter should I use for a 30 6kw photovoltaic system

What size inverter should I use for a 30 6kw photovoltaic system

-

What size inverter should I use for a 12v 180a battery

What size inverter should I use for a 12v 180a battery

-

What size inverter should I use for a 12v 60ah

What size inverter should I use for a 12v 60ah

Commercial & Industrial Solar Storage Market Growth

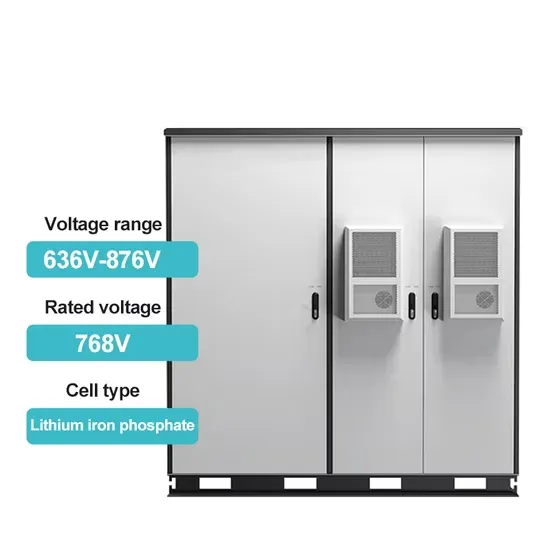

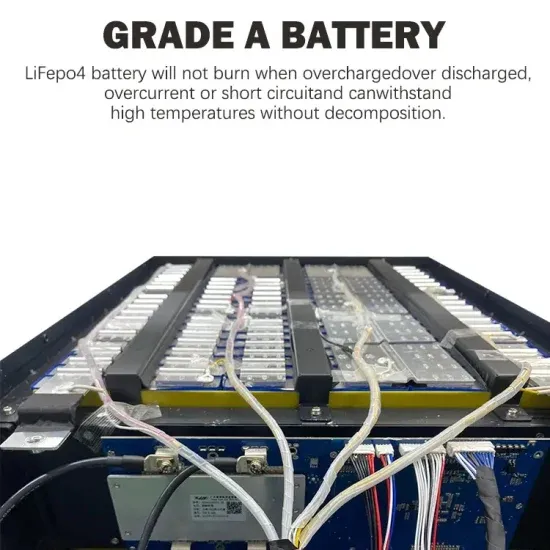

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.