Battery Manufacturing Machines: The Backbone of

Battery manufacturing machines are the unsung heroes behind the rapid advancement of energy storage technologies. These highly specialized

Get Price

Energy storage lead-acid battery processing technology

Shandong Xinxu Group is a comprehensive enterprise group whose business covers the production of high-end power, energy storage batteries and carp batteries, repair of lead-acid

Get Price

Towards Solventless Processing of Thick Electron-Beam

Main Objective: To achieve 1) significant electrode process energy savings; 2) ultra-high electrode processing speed; and 3) utilize much more compact equipment than conventional drying

Get Price

Battery Equipment Solutions for Cell Manufacturers

Commercial manufacturing and R&D Battery Equipment solutions for lithium-ion battery, supercapacitor and energy storage system manufacturers.

Get Price

Battery Processing Systems | Quintus Technologies

Solid-state battery (SSB) technology has been under development for years, offering significant improvements in safety, charging times, and energy

Get Price

Lithium-Ion Battery Manufacturing, Processing

Explore advanced thermal processing solutions for lithium-ion battery manufacturing, ensuring quality and efficiency in production.

Get Price

Energy storage system: Current studies on batteries and power

The paper summarizes the features of current and future grid energy storage battery, lists the advantages and disadvantages of different types of batteries, and points out

Get Price

Advancements in Dry Electrode Technologies:

To address the urgent demand for sustainable battery manufacturing, this review contrasts traditional wet process with emerging dry

Get Price

Energy Storage & Conversion Manufacturing

Processing level – innovating in manufacturing processes to improve productivity, quality, and eco-friendliness. Machine level – creating new manufacturing machinery and improving

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get Price

Data Center Energy Storage Industry Insights Report

Executive Summary The data center industry is evolving rapidly with unprecedented speed and innovation, with battery storage solutions emerging as a key focus. To help industry

Get Price

Lithium-Ion Battery Manufacturing, Processing & Recycling

Explore advanced thermal processing solutions for lithium-ion battery manufacturing, ensuring quality and efficiency in production.

Get Price

Advanced lithium-ion battery process manufacturing equipment

Manufacturing equipment evaluation highlights significant challenges in electrode preparation, cell assembly, and finishing. Using space-saving machinery and cost-effective,

Get Price

Taking battery manufacturing to the next level

A comprehensive review of the state of the art for battery electrode processing informs researchers, battery manufacturers and other industry stakeholders on key technical

Get Price

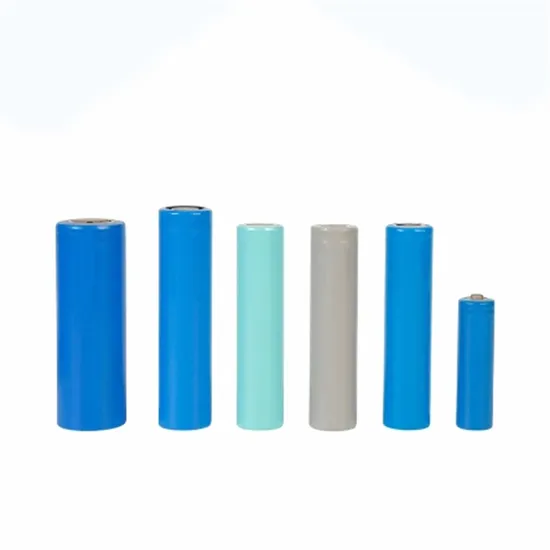

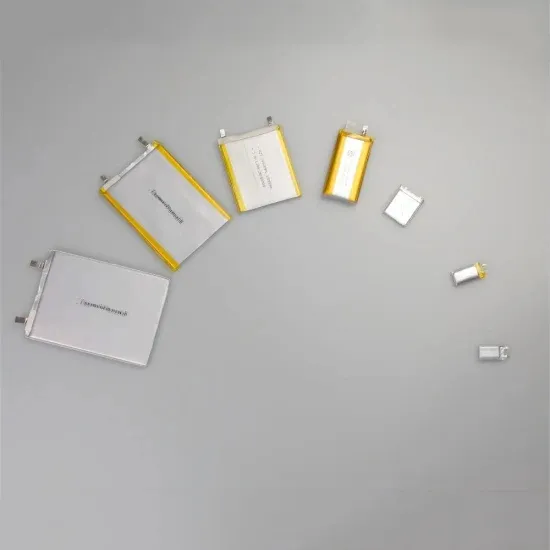

Lithium-Ion Batteries: Mineral Processing, Applications, Recycling

Explore lithium-ion battery applications, from EVs to medical devices, and see how mineral processing and recycling tech enable sustainable production.

Get Price

Advanced electrode processing for lithium-ion battery

In this Review, we discuss advanced electrode processing routes (dry processing, radiation curing processing, advanced wet processing and 3D-printing processing) that could

Get Price

What are the energy storage battery production equipment?

Energy storage battery production equipment plays a pivotal role in the manufacturing process of batteries used for energy storage, fundamentally ensuring efficiency

Get Price

Technology Strategy Assessment

About Storage Innovations 2030 This technology strategy assessment on thermal energy storage, released as part of the Long-Duration Storage Shot, contains the findings from the Storage

Get Price

Battery Manufacturing | Matthews Engineering

As architects of industrial excellence, we deliver battery manufacturing expertise and advanced production solutions for the battery industry.

Get Price

Lithium Battery Processing Equipment: Best Way to Dispose of

The proliferation of lithium-ion batteries (LIBs) in consumer electronics, electric vehicles (EVs), and renewable energy systems has exponentially increased the demand for

Get Price

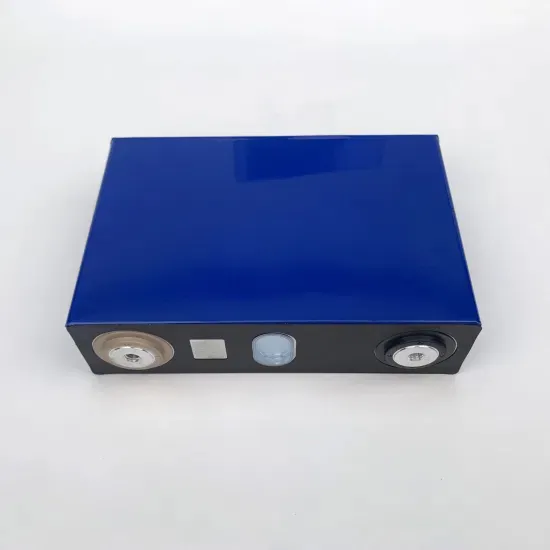

The Manufacturing Process of Lithium Batteries Explained

Lithium battery manufacturing encompasses a wide range of processes that result in the production of efficient and reliable energy storage solutions. The demand for lithium batteries

Get Price

Brief Introduction To Machines Used In Battery Manufacturing

From raw material processing to final assembly and testing, each stage in battery production relies heavily on advanced technology to meet the growing demand for high

Get Price

Six benefits of thermal batteries in manufacturing

A new crop of innovative companies is racing to commercialize and scale up thermal batteries, a novel technology for storing and delivering

Get Price

Battery Manufacturing Machines: The Backbone of Modern Energy Storage

Battery manufacturing machines are the unsung heroes behind the rapid advancement of energy storage technologies. These highly specialized machines automate

Get Price

Processing and Manufacturing of Electrodes for Lithium-Ion Batteries

Hawley, W.B. and J. Li, Electrode manufacturing for lithium-ion batteries – analysis of current and next generation processing. Journal of Energy Storage, 2019, 25, 100862.

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get Price

More related information

-

China Energy Storage Equipment Processing

China Energy Storage Equipment Processing

-

Pakistan energy storage equipment processing factory

Pakistan energy storage equipment processing factory

-

Oceania Flywheel Energy Storage Equipment Processing Plant

Oceania Flywheel Energy Storage Equipment Processing Plant

-

Moldova household energy storage equipment manufacturer

Moldova household energy storage equipment manufacturer

-

Djibouti Centralized Energy Storage Equipment Factory

Djibouti Centralized Energy Storage Equipment Factory

-

Huawei s complete energy storage equipment

Huawei s complete energy storage equipment

-

Energy storage equipment manufacturing and contract manufacturing

Energy storage equipment manufacturing and contract manufacturing

-

Madagascar Coal-to-Electricity Energy Storage Equipment Company

Madagascar Coal-to-Electricity Energy Storage Equipment Company

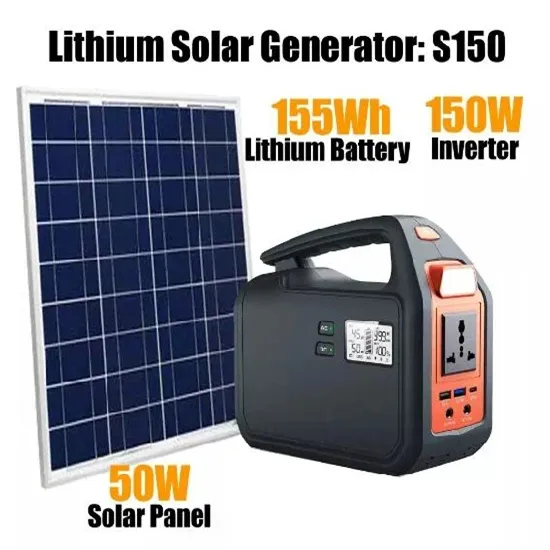

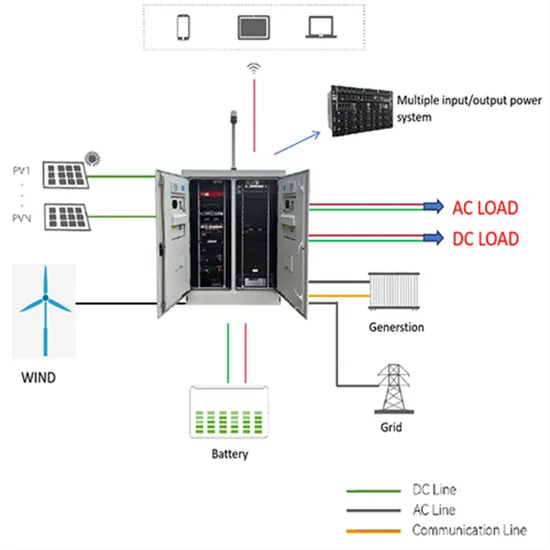

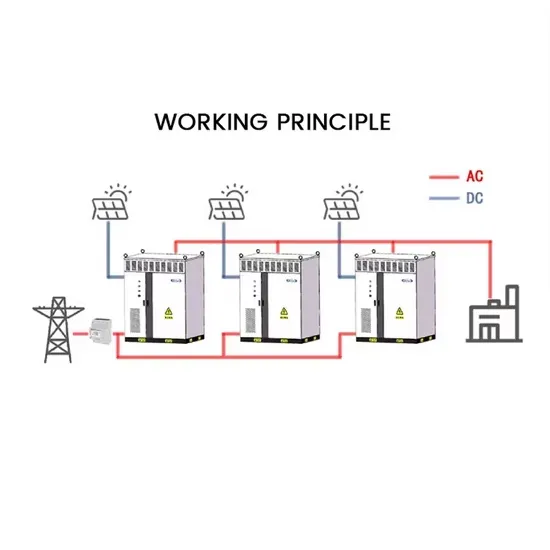

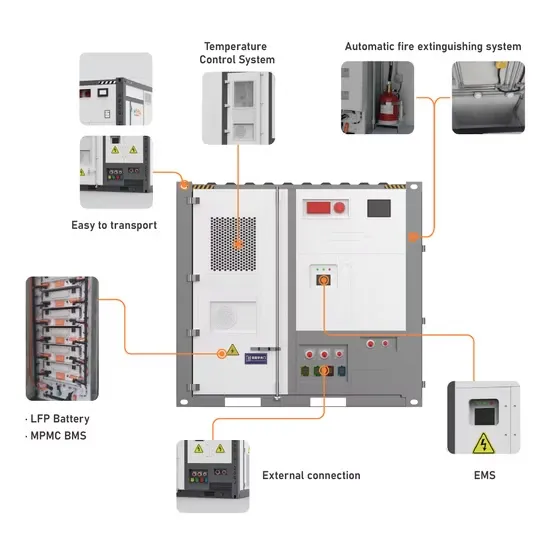

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.