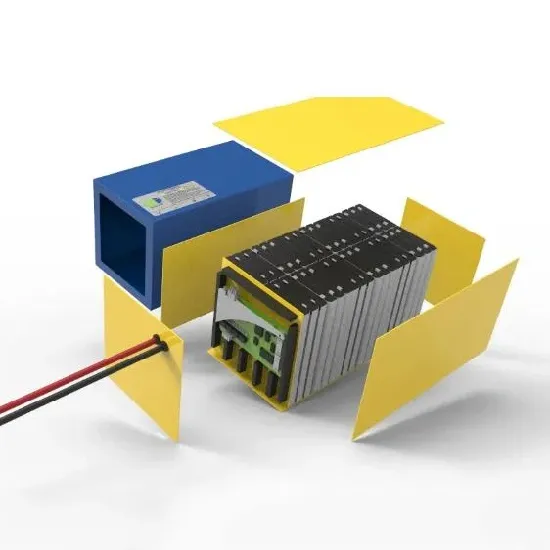

Huiyao Laser Semi-Automated Energy Storage Prismatic Battery

The Huiyao Laser Energy Storage Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It

Get Price

Energy Storage Quality Control | Applus+ USA

They ensure reliable BESS solutions that meet industry standards and quality requirements and improve BESS performance, which is measured through key indicators such as capacity,

Get Price

Challenges and opportunities for high-quality battery production at

Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

Get Price

ISO Certifications for Battery Manufacturing Businesses, Requirements

Each ISO standard applicable to battery manufacturing has specific requirements to ensure quality, safety, sustainability, and efficiency. Below is a breakdown of the

Get Price

Electricity explained Energy storage for electricity generation

Energy storage for electricity generation An energy storage system (ESS) for electricity generation uses electricity (or some other energy source, such as solar-thermal energy) to charge an

Get Price

Quality Control and Testing for Battery Energy Storage Systems

CEA''s factory audits utilize our time-tested 400+ point checklist to provide industry-leading insights into the production processes and quality standards of any storage manufacturer''s

Get Price

ISO Certifications for Battery Manufacturing

Each ISO standard applicable to battery manufacturing has specific requirements to ensure quality, safety, sustainability, and efficiency.

Get Price

Clean Room atmosphere requirements for battery

The battery market has witnessed significant growth in recent years driven by growing demand for electric vehicles (EV) and green electricity

Get Price

Quality management and the future of battery

As the energy transition and electrification of mobility drive the explosive demand for batteries, Christophe Mazeaud, director of Battery

Get Price

Early Quality Classification and Prediction of Battery Cycle Life in

One feasible approach is the use of predictive quality models to identify the cell quality before entering the aging step to reduce the process time or even eliminate the entire

Get Price

Key methods and implementation strategies for optimizing battery

With the continuous development of battery technology, batteries, as the core components of energy storage, are more and more widely used in various fields. However, quality control

Get Price

EV Battery Production. Optimized.

If you''re an EV battery producer, your success depends on strategically upscaling battery gigafactory operations and maintaining extraordinary throughput, quality and yield. The right

Get Price

BESS Quality Manufacturing and QC for Energy Storage Systems

Understand how Battery Energy Storage Systems (BESS) are made. Learn key steps, QC tests to ensure safe, efficient and reliable battery energy storage solutions.

Get Price

QUALITY ASSURANCE FOR BATTERY STORAGE

Safety: components and systems including functional safety Reliability: consideration of operating conditions and system behavior with aged components Performance: efficiency and

Get Price

Energy Storage Systems (ESS) Policies and Guidelines

Energy Storage Systems (ESS) Policies and GuidelinesEnergy Storage Systems (ESS) Policies and Guidelines

Get Price

Quality Requirements for Battery Energy Storage Systems

Purchaser intervention activities are identified through the selection of one of four conformity assessment system (CAS) levels based on a risk and criticality assessment. The applicable

Get Price

Quality Management for Battery Production: A Quality Gate Concept

In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this paper. Goal is the definition of

Get Price

Energy Storage Quality Control | Applus+ USA

Enertis Applus+''s highly specialized BESS quality control and quality assurance services cover the planning and manufacturing phases of battery energy storage systems projects. They

Get Price

Challenges and opportunities for high-quality battery

Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery

Get Price

Successful planning of battery cell production | Festo GB

Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Price

Quality Control and Testing for Battery Energy

CEA''s proactive and robust Quality Control and Testing program proactively identifies and resolves issues at every stage of battery energy storage system

Get Price

From Mining to Manufacturing: Scientific Challenges and

This Review explores the status and progress made over the past decade in the areas of raw material mining, battery materials and components scale-up, processing, and

Get Price

The Manufacturing Process of Lithium Batteries

Lithium battery manufacturing encompasses a wide range of processes that result in the production of efficient and reliable energy storage solutions. The

Get Price

BATTERY ENERGY STORAGE SYSTEMS

INTRODUCTION 2.ENERGY STORAGE SYSTEM SPECIFICATIONS 3. REQUEST FOR PROPOSAL (RFP) A.Energy Storage System technical specications B. BESS container and

Get Price

Quality Control and Testing for Battery Energy

CEA''s factory audits utilize our time-tested 400+ point checklist to provide industry-leading insights into the production processes and quality standards

Get Price

Key methods and implementation strategies for

With the continuous development of battery technology, batteries, as the core components of energy storage, are more and more widely used in various

Get Price

An Overview of

The EU Batery Regulation contains articles about the restriction of substances, carbon footprint, recycled content, batery performance and durability, removability, safety of stationary batery

Get Price

6 FAQs about [Quality requirements for energy storage battery production]

What are the key requirements for a battery quality management system?

Its key requirements include: Establishment of a QMS: Develop a structured quality management system tailored to battery manufacturing processes. Documentation: Maintain records of quality policies, objectives, and operational processes. Customer Focus: Ensure that all products meet customer expectations and comply with regulatory requirements.

Why are ISO standards important in battery manufacturing?

ISO (International Organization for Standardization) standards ensure that products, services, and systems are reliable, efficient, and safe. In battery manufacturing, these standards help align operations with global norms, foster sustainability, and reduce risks.

How sustainable is battery production?

Finally, we mention that the sustainability of battery production is becoming an increasingly important manufacturing performance metric. For instance, an estimated 30–65 kWh are consumed in the factory for every kWh of cells produced 45, 87.

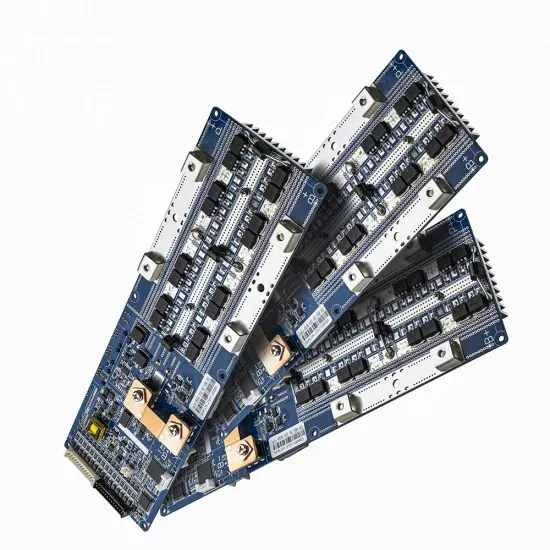

What is quality-oriented production planning in Assembly of battery modules?

A tool for quality-oriented production planning in assembly of battery modules was developed by , defining critical product and process characteristics and deriving appropriate quality assurance systems using a measurement equipment catalogue.

How important is quality control in battery production?

Generally speaking, a strong emphasis on quality and quality control can be a powerful lever to minimize wasted material and energy during battery production. Given the frequency, severity, and inevitability of battery quality issues, both battery producers and manufacturers of battery-containing products must manage battery quality.

What is battery quality?

We now consider a second definition of battery quality: conformance. Conformance refers to how well a manufactured product conforms to its design 25. The battery industry often refers to nonconformance as “cell-to-cell variability” 22, 55, 56, 80.

More related information

-

Sodium-ion energy storage battery mass production

Sodium-ion energy storage battery mass production

-

Colombian home energy storage battery production company

Colombian home energy storage battery production company

-

Tonga quality energy storage battery manufacturer

Tonga quality energy storage battery manufacturer

-

Ess energy storage battery production factory

Ess energy storage battery production factory

-

Energy storage battery production work

Energy storage battery production work

-

Energy storage battery charging temperature requirements

Energy storage battery charging temperature requirements

-

Heishan Energy Storage Battery Production

Heishan Energy Storage Battery Production

-

Fire protection requirements for energy storage battery banks

Fire protection requirements for energy storage battery banks

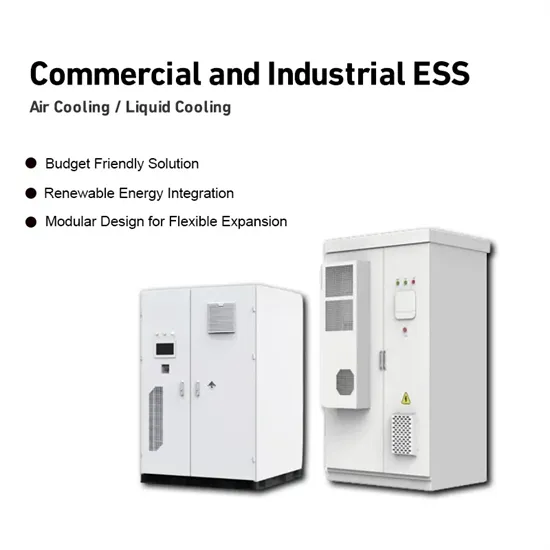

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.