BU-303: Confusion with Voltages

The voltage behavior under a load and charge is governed by the current flow and the internal battery resistance. A low resistance produces low fluctuation under load or charge; a high

Get Price

Current Imbalance in Parallel Battery Strings

Sixteen of these modules combine to create a full battery pack. Battery management systems (BMSs) typically treat each parallel string as a

Get Price

Voltage difference in DIY battery pack

With how low the voltage differences are, you don''t need to worry about any resistors. Altho, if you want to be safer, you could just put a small ceramic resistor between

Get Price

Parallel then Series or Series then Parallel

Hence it is important to measure the voltage of each string and set limits on the differences. The difficulty occurs if the differences are too great. Then a decision has to be

Get Price

Battery Cell, Module, Pack, what`s the Difference?

A battery cell is the most basic functional unit of a lithium-ion battery. Looking at its structure, each battery cell contains five key

Get Price

Parallel then Series or Series then Parallel

Hence it is important to measure the voltage of each string and set limits on the differences. The difficulty occurs if the differences are too great.

Get Price

Battery string

Battery string This refers to a configuration of multiple battery cells or modules connected together in a series, parallel, or a combination of both to create a

Get Price

Battery Pack Sizing

Hence, most battery pack sizing studies start with the Energy, Power and Working Voltage Range (Inputs to Pack Sizing is a more complete list). The

Get Price

Battery Pack Cell Voltage Difference And Solution Part 2

We have introduced voltage difference in battery packs and used it as an important criterion for measuring the quality of batteries. At this time, we''ll review how to prevent voltage

Get Price

Strings, Parallel Cells, and Parallel Strings

Additionally, because no two cells are exactly the same, different currents will flow through each battery pack due to differing internal resistances, creating difference in state of charge

Get Price

Introduction: What Is a Lithium-Ion Battery Pack?

Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

Get Price

lithium ion

What voltage difference could indicate that some cells are not as good as others? The first thing you should worry about the voltage of the cells: If one of them exceeds the max

Get Price

A Low Cost and Fast Cell-to-Cell Balancing Circuit for

This paper proposes a fast cell-to-cell balancing circuit for lithium-ion battery strings. The proposed method uses only one push-pull converter to

Get Price

Battery Cell, Module or Pack. What''s the difference?

The manufacturing of battery cells compared to battery packs or modules are two very different industrial processes. Battery cell production is

Get Price

BU-303: Confusion with Voltages

The phosphate-based lithium-ion has a nominal cell voltage of 3.20V and 3.30V; lithium-titanate is 2.40V. This voltage difference makes these chemistries incompatible with regular Li-ion in

Get Price

Voltage difference between modules

Each module has 51 volts. I would like to know how much voltage difference are allowed between to modules? I mean more than how much voltage the BMS needs voltage

Get Price

Battery Pack Cell Voltage Difference And Solution Part 2

We have introduced voltage difference in battery packs and used it as an important criterion for measuring the quality of batteries. At this time,

Get Price

BU-303: Confusion with Voltages

The voltage behavior under a load and charge is governed by the current flow and the internal battery resistance. A low resistance produces low fluctuation

Get Price

Battery Voltage: Basics and Importance for Optimal Performance

Battery voltage refers to the electrical potential difference between the two terminals of a battery. It is measured in volts (V) and indicates the amount of energy available

Get Price

How to equalization charge Lithium ion battery

When the lithium-ion battery pack is produced and stored for a long time, due to the difference in static power consumption of each circuit of

Get Price

How to Detect and Keep Types of BMS Voltage for

This helps reduce voltage differences between battery cells. Monitoring and adjustment: During the voltage balancing operation, BMS will

Get Price

48V lithium battery pack the difference between ternary lithium 13

The cost of matching chargers has also increased accordingly. The 13-string battery pack charger voltage is 54.6V; the 14-string battery pack charger voltage is 58.8V. If

Get Price

Cell Capacity and Pack Size

Obviously Cell Capacity and Pack Size are linked. The total energy content in a battery pack in it''s simplest terms is S x P x Ah x Vnom.

Get Price

Voltage difference in DIY battery pack

With how low the voltage differences are, you don''t need to worry about any resistors. Altho, if you want to be safer, you could just put a small

Get Price

The Complete Guide To A Battery Management System

When charging, the protection board will monitor the voltage of each string of the battery pack in real-time, as long as one of the strings

Get Price

Management of imbalances in parallel-connected lithium-ion battery

Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the

Get Price

Battery Cell Balancing: What to Balance and How

Cell based termination voltage is usually set to lower value than pack based threshold divided by number of serial cells, so that the difference can allow for a small unbalance.

Get Price

Battery Pack Cell Voltage Difference and Solution Part 1

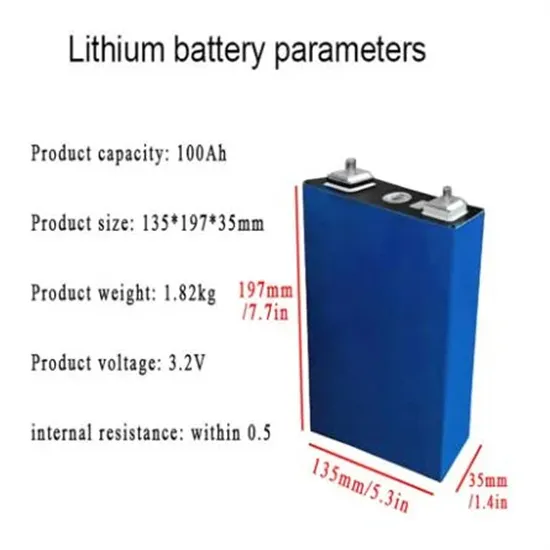

For battery packs, the voltage difference between individual cells is one of the main indicators of consistency. The smaller the voltage difference, the better the consistency of the

Get Price

6 FAQs about [The voltage difference between each string of lithium battery pack]

Can a lithium ion battery pack have multiple strings?

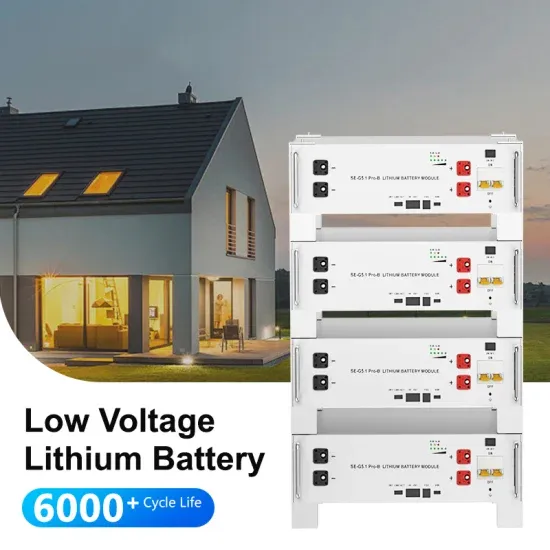

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

Why does a battery pack have a different state of charge?

Additionally, because no two cells are exactly the same, different currents will flow through each battery pack due to differing internal resistances, creating difference in state of charge between the two strings.

What determines the operating voltage of a battery pack?

The operating voltage of the pack is fundamentally determined by the cell chemistry and the number of cells joined in series. The ampere-hour capacity of the pack is determined by the capacity of a cell and the number of cells in parallel. This is the approach used in most passenger car electric vehicles and smaller battery pack designs.

What if there is a voltage difference in a battery pack?

Therefore, you should pay attention to the brand from which you are purchasing your batteries. If there is a gap in the voltage of the battery pack, you can correct it with additional equipment, such as with a BMS, balance charging, etc. Stay tuned for Part 2 of voltage difference: How to prevent voltage difference.

How many volts are in a battery pack?

If each cell is 10 amp hours and 3.3 volts, the battery pack above would be 10 amp hours and 26.4 volts (3.3 volts x 8 cells). For this setup, a BMS capable of monitoring 8 cells in series is necessary. Lithium cells can almost always be paralleled directly together to essentially create a larger cell.

How does voltage difference affect battery performance?

For battery packs, the voltage difference between individual cells is one of the main indicators of consistency. The smaller the voltage difference, the better the consistency of the cells and the better the discharge performance of the battery pack.

More related information

-

Lithium battery pack difference low voltage

Lithium battery pack difference low voltage

-

48v lithium battery pack voltage

48v lithium battery pack voltage

-

What is the charging voltage of a 74v lithium battery pack

What is the charging voltage of a 74v lithium battery pack

-

Lithium battery pack temperature difference

Lithium battery pack temperature difference

-

Lithium battery replacement single string battery pack

Lithium battery replacement single string battery pack

-

36v lithium battery pack voltage

36v lithium battery pack voltage

-

Kiribati lithium battery pack OEM customization

Kiribati lithium battery pack OEM customization

-

220v wall mounted DC power supply lithium battery pack

220v wall mounted DC power supply lithium battery pack

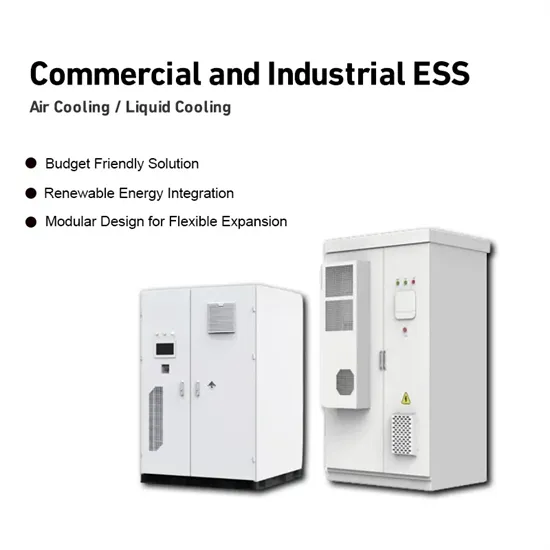

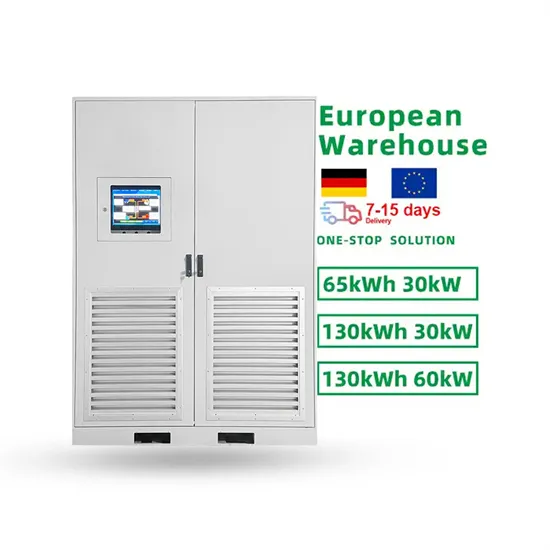

Commercial & Industrial Solar Storage Market Growth

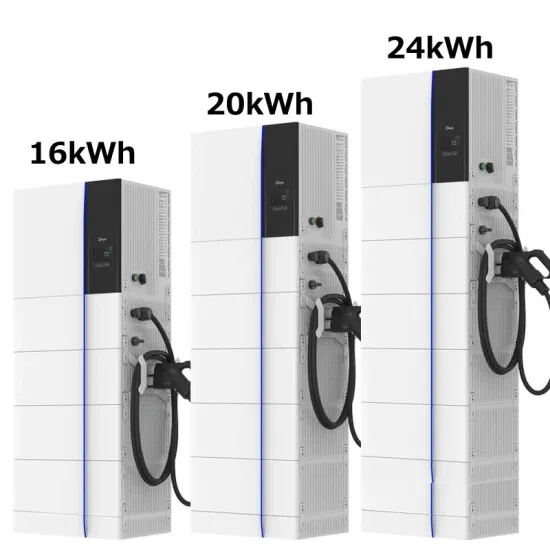

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.