Best Practices for Charging, Maintaining, and Storing

Welcome to our comprehensive guide on lithium battery maintenance. Whether you''re a consumer electronics enthusiast, a power tool user, or an electric

Get Price

Lithium-ion Battery Safety

A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a negative electrode, a separator,

Get Price

EHS Guideline

Purpose Carnegie Mellon University has prepared this guideline to provide safety requirements for purchasing, working with, charging, transporting, handling emergencies, and disposing of

Get Price

Best Practices for Charging, Maintaining, and Storing Lithium

Properly maintaining and caring for your lithium-ion batteries can mitigate the effects of battery aging. By implementing storage guidelines, charging practices, and avoiding excessive

Get Price

Ultimate Guide to Equipment for Lithium Battery Assembly: Types

Each stage requires specialized equipment to handle tasks like coating, cutting, stacking, welding, and testing. The quality and performance of the final battery product heavily

Get Price

Lithium Ion Battery

Li-ion batteries are used in battery packs for portable laptops, power tools and many other devices requiring electrical power. LiPo are commonly seen in applications like RC vehicles where

Get Price

How to Transport Lithium Batteries Safely – Expert Tips

Our battery packaging prioritizes safety with robust materials and designs that meet industry standards for handling and transportation of lithium

Get Price

Understanding Lithium Ion Battery Packs: Types, Uses, and

Lithium ion battery packs are integral to modern technology and sustainable energy solutions. By understanding the different types, their uses, and adhering to safety

Get Price

Key Safety Standards for Lithium Battery Operations

Charger Selection and Use: Chargers used for charging operations must comply with relevant standards and specifications, ensuring reliable quality. Chargers should include safety

Get Price

Introduction to Production Equipment and Testing Methods for Lithium

Lithium-ion battery packs are widely used in various applications, from electric vehicles to energy storage systems. Their production and testing are crucial for ensuring their optimal

Get Price

What Precautions Should You Take When Packing Lithium Ion

Critical reminder: FedEx and UPS require special training certification for employees shipping lithium batteries – always verify your shipping agent''s qualifications. Long

Get Price

Key Safety Standards for Lithium Battery Operations

Electrical Use Safety Standards: Equipment Insulation and Grounding: Lithium battery-powered equipment should have excellent

Get Price

Battery guidance document

Lithium battery test summary – except for button cells installed in equipment (including circuit boards), manufacturers and subsequent distributors of cells or batteries and equipment

Get Price

Introduction to Production Equipment and Testing Methods for

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

Can You Fly With Lithium Batteries? Rules & Guidelines

Flying with lithium batteries? Learn TSA and airline rules for carry-on vs checked bags, Wh limits, spare battery guidelines, and approval steps.

Get Price

How To Ship Batteries | UPS

A UPS guide to help you safely pack and ship many kinds of batteries including lithium metal, damaged or defective batteries and alkaline or certain nonspillable lead-acid batteries.

Get Price

How to Ship Wet, Dry, and Lithium Batteries | FedEx

Learn how to ship your batteries with our guide. Discover how to identify your wet or dry battery and how to secure them for shipping. Our guidelines for shipping lithium batteries will help

Get Price

Top Do''s and Don''ts for Lithium Battery Safety

Use only official charging equipment that matches your battery pack specifications. Charging with the wrong equipment can cause overheating or even fire. Charge batteries on

Get Price

Revive Your Dead Lithium Battery Pack with These Repair Tips

The repair of a lithium battery pack is an important task that requires technical knowledge and skill, but luckily, with some basic knowledge and tools, you can learn how to

Get Price

Lithium Batteries: Safety, Handling, and Storage

Primary lithium batteries feature very high energy density, a long shelf life, high cost, and are non-rechargeable. They are generally used for portable consumer electronics, smoke alarms, light

Get Price

How to Transport Lithium Batteries Safely – Expert Tips

Our battery packaging prioritizes safety with robust materials and designs that meet industry standards for handling and transportation of lithium-ion batteries.

Get Price

Introduction to Production Equipment and Testing Methods for Lithium

This article provides an introduction to the production equipment and testing methods for lithium-ion battery packs, using 2025 industry data to guide your understanding.

Get Price

Battery Spot Welder: Guide for Lithium Battery Packs

Learn how to use a battery spot welder for lithium packs, with tips on equipment, techniques, and ensuring strong, safe welds.

Get Price

Key Safety Standards for Lithium Battery Operations

Charger Selection and Use: Chargers used for charging operations must comply with relevant standards and specifications, ensuring reliable

Get Price

(a) Scope and application

The intent of this guideline is to provide the users of lithium and lithium ion batteries with guidance to facilitate the safe handling of battery packs and cells under normal and emergency conditions.

Get Price

Your 2025 Guide to Lithium Battery Labels

Medical equipment But not all lithium-ion batteries are small. Some are large, high-capacity battery packs used for: Electric vehicles Backup power systems (UPS) Portable

Get Price

6 FAQs about [What equipment should be used with lithium battery packs ]

What is the purpose of a lithium ion battery guideline?

10.0 Waste Management....................................................................... The intent of this guideline is to provide the users of lithium and lithium ion batteries with guidance to facilitate the safe handling of battery packs and cells under normal and emergency conditions.

How to store lithium ion batteries?

The ideal surface for storing lithium-ion batteries is concrete, metal, or ceramic or any non-flammable material. Batteries can be stored in a metal cabinet such as a chemical-storage cabinet, make sure that batteries are not touching each other. It is recommended to have in place a fire detector in the storage area.

What are lithium ion batteries used for?

They power devices such as mobile telephones, laptop computers, tablets, cameras, power tools, electric vehicles, and machinery, and are also used in large Energy Storage Systems (ESS). Lithium-ion batteries may present several health and safety hazards during manufacturing, use, emergency response, disposal, and recycling.

How to transport lithium batteries safely?

Here’s a comprehensive guide on how to transport lithium batteries safely: 1. Understanding Regulations and Guidelines Understand Regulations: Familiarize yourself with international and local regulations governing lithium battery transport. Regulations may vary based on transportation mode (by air, road, sea) and quantity of batteries.

Do lithium batteries need to be kept cool and dry?

By keeping your batteries in a cool and dry place, you can reduce the rate of corrosion and extend their shelf life. By following these guidelines for long-term storage and battery corrosion prevention, you can ensure that your lithium batteries remain in optimal condition and ready for use when needed.

Why is it important to keep lithium batteries cool?

It is important to keep lithium batteries cool to maintain their performance. Avoiding hot environments such as cars on hot days and storing batteries in shaded or temperature-controlled areas can help prevent capacity loss and extend battery lifespan. What are the recommended charging characteristics for lithium-ion batteries?

More related information

-

What devices are lithium battery packs used in

What devices are lithium battery packs used in

-

Lithium battery packs used in series and parallel

Lithium battery packs used in series and parallel

-

What is the best voltage balance for lithium battery packs

What is the best voltage balance for lithium battery packs

-

What is the service life of lithium battery energy storage equipment

What is the service life of lithium battery energy storage equipment

-

What voltages are available for lithium battery packs

What voltages are available for lithium battery packs

-

What kind of energy storage lithium battery is mainly used for

What kind of energy storage lithium battery is mainly used for

-

What lithium battery packs are available in the United States

What lithium battery packs are available in the United States

-

Lesotho lithium battery environmentally friendly energy storage equipment

Lesotho lithium battery environmentally friendly energy storage equipment

Commercial & Industrial Solar Storage Market Growth

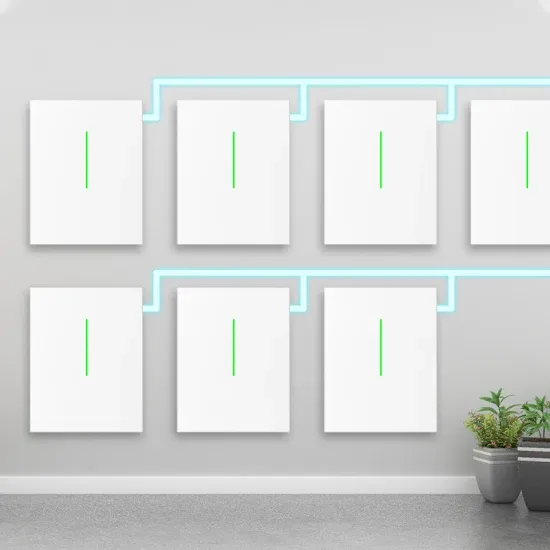

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.