UL 9540A TEST METHOD FOR BATTERY ENERGY

This test is conducted on the smallest individual battery cell within the Battery Energy Storage System (BESS). A reliable and repeatable method

Get Price

How to Test New LiFePO4 Cells: Step-by-Step Guide

However, before integrating them into your project, it''s crucial to test their performance and identify any potential defects. This comprehensive guide will

Get Price

Testing Battery Cells Modules and Packs with a Single Instrument

Testing Battery Cells, Modules and Packs with a Single Instrument Battery technology continues to evolve, providing powerful energy solutions for various applications,

Get Price

How to effectively test battery cells: a comprehensive review

Cell testing can be divided into three main categories: life testing, performance testing and safety testing. Below is an outline on effectively testing battery cells. Life tests aim

Get Price

How To Troubleshoot A Battery In A PWRcell System?

Verify the PWRcell battery cabinet is in the On position. Verify the DC breaker is on. Disable and re-enable the battery cabinet on the inverter to reset it. See the How do I power cycle my

Get Price

Battery Cabinet Performance Testing: The Critical Gateway to

Can your battery cabinets withstand real-world operational stresses while maintaining optimal efficiency? As global energy storage capacity surges past 1,500 GWh in 2024, performance

Get Price

ESS Battery Cell Performance Testing Cabinet

The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical and thermal performance of energy storage system (ESS) battery cells.

Get Price

Eaton-Battery-Handbook-BAT11LTA.PDF

You can replace the bad battery with a fully charged unit but you also need to test the health of the entire string to the cell level to identify if additional strain from the faulty battery damaged

Get Price

Testing Battery Cells Modules and Packs with a

Testing Battery Cells, Modules and Packs with a Single Instrument Battery technology continues to evolve, providing powerful energy solutions

Get Price

How to Test New LiFePO4 Cells: Step-by-Step Guide and Tools

However, before integrating them into your project, it''s crucial to test their performance and identify any potential defects. This comprehensive guide will walk you through the process of

Get Price

Home Energy Storage Battery Testing | Rechargeable Power

-RPE Demonstrates how we test batteries here at the factory using a Neware Load testing Device system for a UZ energy Battery 100Ah. -Welcome to Rechargeable...

Get Price

Proper Battery Testing Steps & Procedure

In this article we lay out the steps to testing a battery, capacity, internal resistance, voltage and voltage sag.

Get Price

UL 9540A TEST METHOD FOR BATTERY ENERGY

UL 9540A Test Apparatus for evaluating thermal runaway fire propagation in Battery Energy Storage Systems, including cell level test, module level test,

Get Price

How to effectively test battery cells: a comprehensive

Cell testing can be divided into three main categories: life testing, performance testing and safety testing. Below is an outline on effectively

Get Price

How to Choose Single Cell BMS or Multiple BMS?

The BMS ensures that each cell remains balanced and operates efficiently, extending the vehicle''s range and lifespan. Renewable Energy

Get Price

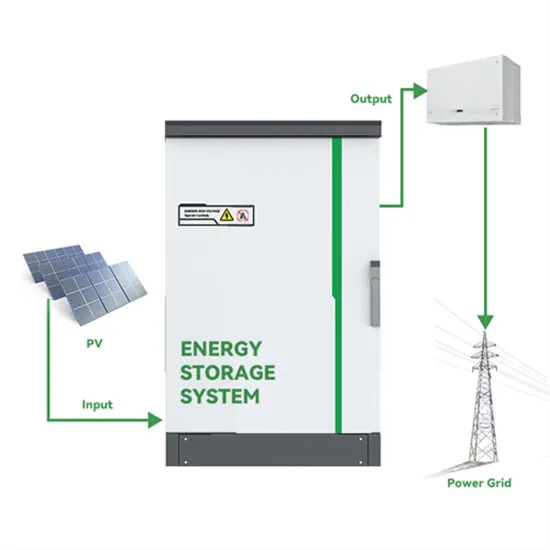

How to test the energy storage cabinet level

Performance testing is a critical component of safe and reliable deployment of energy storage systems on the electric power grid. Specific performance tests can be applied to individual

Get Price

Energy Storage System Buyer''s Guide 2025

The system consists of: Ready to install liquid-cooled battery energy storage system with one (2-hour version) or two (4-hour version) battery cabinets, and

Get Price

Home Energy Storage Battery Testing | Rechargeable Power Energy

-RPE Demonstrates how we test batteries here at the factory using a Neware Load testing Device system for a UZ energy Battery 100Ah. -Welcome to Rechargeable...

Get Price

Energy Storage Cabinet Test Solution Design: A Step-by-Step

Let''s face it – energy storage cabinets are like the unsung heroes of our renewable energy revolution. These metal giants quietly store solar power for cloudy days and wind

Get Price

Battery Cabinet Performance Testing: The Critical Gateway to Energy

Can your battery cabinets withstand real-world operational stresses while maintaining optimal efficiency? As global energy storage capacity surges past 1,500 GWh in 2024, performance

Get Price

New Energy Battery Cabinet Safety Test

Battery cabinet fire propagation prevention design: If an energy storage system is not compartmentalized, a thermal runaway event in a single battery is extremely likely to spread to

Get Price

Samsung UL9540A Lithium-ion Battery Energy Storage

Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety standards of the UL9540A

Get Price

Series:Oasis-L215 OasisL215

The energy storage battery part adopts a single 280Ah/3.2V lithium iron phosphate cell, assembled by series-parallel way, 48 strings of single cells form a battery box, 5 battery boxes

Get Price

How To Test A Battery?

Battery testing evaluates capacity, voltage, and health using tools like multimeters, load testers, and impedance analyzers. Key steps include checking open-circuit voltage (OCV), performing

Get Price

836kWh Liquid Cooled Battery Storage Cabinet

Problem: Energy storage systems must meet stringent safety standards and regulations to ensure reliability. Solution: The eFlex 836kWh system meets

Get Price

Galaxy Lithium-ion Battery Cabinet Installation and Operation

This manual provides installation and operation instructions for the Galaxy Lithium-ion Battery Cabinet.

Get Price

How to Check Battery Cell Voltage

To check battery cell voltage, you use a digital multimeter to measure the voltage across each individual cell terminal. This simple process reveals the health and charge status

Get Price

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

The above questions are the basics on selecting a UPS with battery system, however there are many factors to consider. The most common topology of a UPS with a battery system is the

Get Price

How to test battery cells?

How to test battery cells?Thermal imaging is used to check for "hot spots" which would indicate points of high thermal stress in the cell or the battery pack. It is a photographic technique

Get Price

6 FAQs about [How to test the single cell of new energy battery cabinet]

What are the steps in battery testing?

The steps in battery testing involve a visual inspection for physical damage, a voltage check to make sure the battery is within a normal operating range, a capacity test to compare current capacity to rated capacity, and an internal resistance test to assess the battery's overall health.

How do you test a LiFePO4 battery?

Testing the capacity of your LiFePO4 cells helps you evaluate their energy storage potential and performance. This step ensures that the battery can meet the power demands of your project. Tools Needed: A battery capacity tester (a device designed to discharge batteries at a controlled rate and measure their total energy output).

What is a battery capacity test?

Capacity Test: A capacity test is a great way to measure how useful the battery will be because you can see how much energy it can hold. It can also be useful in ascertaining the overall health of the battery by comparing the ratio of the energy it can actually store to the energy it's rated as being able to store.

What should a battery capacity tester do?

Battery Capacity Tester: Determines the cell's energy storage and output capabilities. Safety Equipment: Includes gloves, eye protection, and a respirator (if necessary) to minimize risks during testing. Pro Tip: Investing in high-quality tools ensures precise readings and reduces the risk of errors during testing.

How do you test a battery?

One of the first and simplest tests is checking the voltage of the newly received cells. Proper voltage levels indicate that the batteries were shipped and stored under the right conditions. Here’s how to measure voltage accurately: Tools Needed: A multimeter (an essential tool for measuring electrical voltage, current, and resistance).

How do you test a lithium battery?

By testing lithium batteries you ensure the reliable and safe operation of batteries. Whether you're dealing with testing complete lithium-ion batteries or raw lithium-ion cells, thorough testing is essential to assess their condition, capacity, and overall health. How Do I Test A Battery? Visual Inspection: The first step is a visual Inspection.

More related information

-

New energy battery cabinet adds single cell

New energy battery cabinet adds single cell

-

Cost of replacing a single unit in a new energy battery cabinet

Cost of replacing a single unit in a new energy battery cabinet

-

How many years can the new energy battery cabinet be used

How many years can the new energy battery cabinet be used

-

How long does it take to replace the new energy battery cabinet

How long does it take to replace the new energy battery cabinet

-

How many layers of protection does the new energy battery cabinet have

How many layers of protection does the new energy battery cabinet have

-

How much is the load of new energy battery cabinet

How much is the load of new energy battery cabinet

-

Aluminum profile new energy battery cabinet

Aluminum profile new energy battery cabinet

-

How long does the energy storage battery cabinet last

How long does the energy storage battery cabinet last

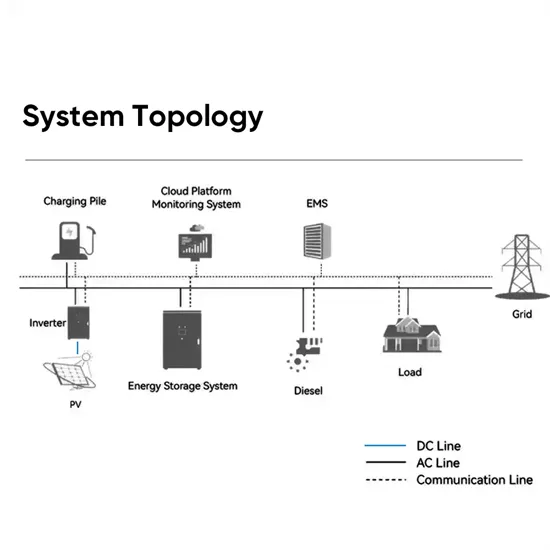

Commercial & Industrial Solar Storage Market Growth

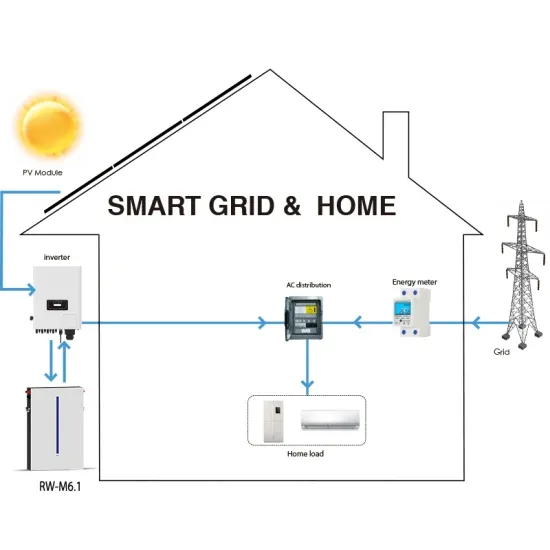

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.