Optimal Impedance Design for Dual-Branch High-Frequency Inverter

High-frequency inverters often need to operate under dynamically varying loads, while the inverter structure allows only very narrow loads. In this article, an optimal impedance

Get Price

Review of very high frequency power converters and

With the increasing demand for volume reduction and efficiency improvement, very high frequency (VHF) power converters (30–300 MHz)

Get Price

A High Frequency Variable Load Inverter Architecture

This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive

Get Price

Circuit structure of high-frequency inverter.

Download scientific diagram | Circuit structure of high-frequency inverter. from publication: Power Quality Control System of High-Power-Density Switching

Get Price

Nine-level high-frequency inverter

Abstract: In the high-frequency AC (HFAC) power distribution system, problems such as high switching frequency, a complicated circuit configuration and difficult parameter design still exist

Get Price

Frequency inverter design

Frequency inverters have always been limited to "normal torque" applications while high torque, low rpm applications have been the domain of DC drives. This has changed recently with the

Get Price

Frequency Converter Structure: A Deep Dive for Efficiency and

Introduction: A frequency converter, often referred to as a frequency inverter, is a crucial element in many electrical systems. But what exactly lies behind it? Essentially, a

Get Price

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

This application report documents the concept reference design for the DC-DC Stage and the DC-AC Converter section that can be used in the High-Frequency Inverter using TMS320F28069,

Get Price

High-Frequency Inverters: From Photovoltaic, Wind, and Fuel

The inverter (see Fig. 29.7) described in this section comprises a dc–dc zero-ripple boost converter (ZRBC), which generates a high-voltage dc at its output followed by a soft

Get Price

Buy Solar Products In Kenya Online From Solar Shop

Kenya''s leading online solar products store for top-quality solar panels, water heaters, inverters, outdoor lighting, water pumps, batteries, and more.

Get Price

Multilevel Inverters for Electric Vehicle Applications

Multilevel inverters are uniquely suited for this application because of the high VA ratings possible with these inverters [2, 3]. Where generated ac voltage is available such as from an alternator

Get Price

High-Frequency Inverters: From Photovoltaic, Wind, and

Schematic diagrams [3] and [4] of (a) coupled inductor structure for reducing the HF current ripple; (b) half-bridge active filter, which compensates for the low-frequency harmonic-current-ripple

Get Price

Inverters and converters

The inverter circuit creates a high-frequency alternating current that is supplied to the coil. In the case of fluorescent lights, this high-frequency alternating

Get Price

A New Architecture for High-Frequency Variable-Load Inverters

Abstract—Efficient generation and delivery of high-frequency (HF, 3-30 MHz) power into variable load impedances is difficult, resulting in HF inverter (or power amplifier) systems that are

Get Price

Advanced Modulation Techniques and Topological Innovations in High

A comparative analysis of existing HFLIs in terms of switching frequency, soft-switching capability, modulation strategies, power rating, and efficiency is discussed.

Get Price

Review on Silicon Carbide based High-Fundamental

Recent research and development efforts in SiC inverters for electric drive applications highlight a strong focus on achieving high power density, high efficiency, and high-frequency operation.

Get Price

Circuit structure of high-frequency inverter.

Download scientific diagram | Circuit structure of high-frequency inverter. from publication: Power Quality Control System of High-Power-Density Switching Power Supply for Green Environment

Get Price

Nine-level high-frequency inverter

In this paper, a multi-level high-frequency inverter structure based on a forward converter is proposed, which ensures that the input and output are electrically isolated.

Get Price

Advanced Modulation Techniques and Topological Innovations in

A comparative analysis of existing HFLIs in terms of switching frequency, soft-switching capability, modulation strategies, power rating, and efficiency is discussed.

Get Price

Power Frequency Inverter Installation Maintenance in Somaliland

Discover how proper installation and maintenance of power frequency inverters can stabilize Somaliland''s energy infrastructure. This guide covers technical insights, cost-saving strategies,

Get Price

(PDF) A bidirectional, sinusoidal, high-frequency

A new method for the design of a bidirectional inverter based on the sinusoidal pulse-width modulation principle and the use of a low-cost and

Get Price

Advanced Modulation Techniques and Topological Innovations in High

High-Frequency Link inverters (HFLIs) have attracted significant research attention owing to their compact design, high power density, and high efficiency. HFLI systems achieve power

Get Price

Inversion Methods Explained: High Frequency vs Low Frequency

Understand the difference between high frequency and low frequency inverters with this quick article.

Get Price

Design and Construction of a High-Frequency Transformer of

Therefore, it is clear that the design phases of power converters and transformers interact, particularly at high power levels. So, the primary goal of this study is to carry out

Get Price

Somaliland High Frequency Inverter

A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

Get Price

6 FAQs about [Somaliland high frequency inverter structure]

What is a high frequency variable load inverter architecture?

This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power combiner.

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Which power supply topologies are suitable for a high frequency inverter?

The power supply topologies suitable for the High-Frequency Inverter includes push-pull, half-bridge and the full-bridge converter as the core operation occurs in both the quadrants, thereby, increasing the power handling capability to twice of that of the converters operating in single quadrant (forward and flyback converter).

Can a high-frequency variable load inverter directly drive widely variable loads?

Typically a tunable matching network is used to transform the varying load into a ciency and impairing transient response. This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive widely variable loads.

Can hfvli drive a wide load range RF inverter?

From these results it is evident that the HFVLI prototype is successful in the goal of driving a wide load range at high power power levels. rst physical prototype of of a wide load range RF inverter based on the proposed high frequency variable-load inverter topology was designed and built along with an e ciency optimizing controller.

What is the HM scheme for fdcl inverter?

heme. The HM scheme is implemented for the ac–ac converter stage. For the FDCL topology, the output stage is +−HF 1 0UTVTWTUUTVVTWWTUBVBWBUUBVVBWWBFIGURE 29.2 Diagram of gate-drive-signal generation for the HFL inverter .where PWMx (x D a, b, or c) denotes the inary compara-tor output between reference

More related information

-

Inverter high frequency hybrid

Inverter high frequency hybrid

-

High frequency inverter for communication

High frequency inverter for communication

-

Silicon Carbide High Frequency Inverter

Silicon Carbide High Frequency Inverter

-

12v household high frequency sine wave inverter

12v household high frequency sine wave inverter

-

Morocco high frequency inverter installation factory

Morocco high frequency inverter installation factory

-

Lesotho high frequency inverter manufacturer

Lesotho high frequency inverter manufacturer

-

High frequency inverter crystal

High frequency inverter crystal

-

Simple high frequency inverter design

Simple high frequency inverter design

Commercial & Industrial Solar Storage Market Growth

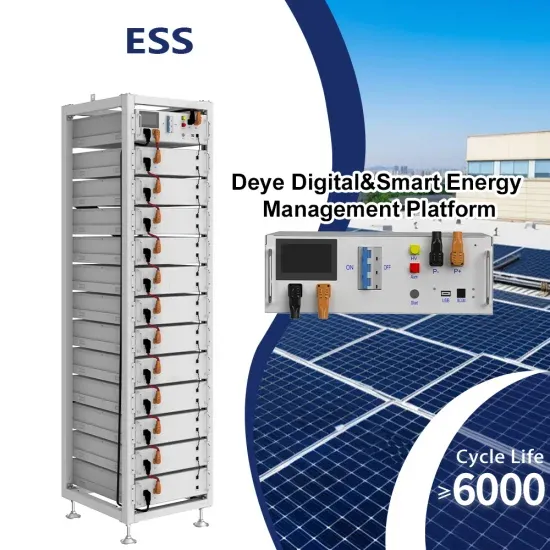

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.