What Are Solar Panels Made Of?

Discover the essential components of solar panels, including photovoltaic cells, glass, and frames. Learn how Rayzon Solar manufactures high-quality solar panels for maximum efficiency and

Get Price

How Are Solar Panels Made? A Comprehensive Overview

In this guide, we''ll explain how solar panels are made, what they''re made of, and where they''re manufactured to give you a more holistic view of solar technology. Solar panels are

Get Price

What are solar panels made of? [Materials

Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to

Get Price

What Are Solar Panels Made Of? Detailed Materials Breakdown

At the core of every solar panel are several materials designed to capture the sun''s energy and convert it into usable electricity. Solar panels typically consist of silicon solar

Get Price

What is Solar Panel Made Of: Materials and Their Functions

Discover what solar panels are made of, their components, how they work, benefits, challenges, and surprising facts about solar energy.

Get Price

What Are Solar Panels Made Of?

Solar panels contain photovoltaic cells at their foundation because these cells transform sunlight into electrical energy. Silicon functions as the most

Get Price

Solar Photovoltaic Technology Basics | NREL

Photovoltaics (often shortened as PV) gets its name from the process of converting light (photons) to electricity (voltage), which is called the

Get Price

What Are Solar Panels Made Of?

Solar panels contain photovoltaic cells at their foundation because these cells transform sunlight into electrical energy. Silicon functions as the most frequently used semiconductor material

Get Price

How Solar Panels Are Made | A Step-by-Step Guide

Discover how solar panels are made, from silicon extraction to final assembly. Learn their components, types, and manufacturing process.

Get Price

How Are Solar Panels Made? A Comprehensive Overview

At the core of every solar panel are several materials designed to capture the sun''s energy and convert it into usable electricity. Solar panels

Get Price

Breaking Down Solar Panels and What They Are Really Made Of

1 day ago· Solar panels power homes and farms. But what goes into them? Let''s peel back the layers. We''ll look at key parts, materials, and how they come together. If you''re thinking green

Get Price

What are solar panels made of? [Materials breakdown, 2025]

Polysilicon, made from silicon metal, is the key material used to make solar cells. This is because its semiconducting properties allow it to convert sunlight into electricity (i.e. the

Get Price

How Are Solar Panels Made? – Forbes Home

Solar panels are made of various parts that work together to create electricity from sunlight. PV cells, typically made of crystalline silicon (c-Si) or

Get Price

What Are Solar Panels Made Of? Everything You Need to Know

Solar panels are made of six primary components: silicon solar cells, metal frames, glass sheets, 12V wire, and bus wire. Here''s a breakdown of each: Silicon solar cells

Get Price

What are solar panels made of?

In simple terms, solar panels are made of protective layers mounted on a photovoltaic (PV) cell layer with adhesive layers and secured to a frame. PV cells are typically

Get Price

How Are Solar Panels Made Step by Step

But, how are these solar panels made? Here, we''ll guide you through each step of making a solar panel. Making solar panels starts by

Get Price

What Are Solar Panels Made of? Full Materials Guide

Find out what solar panels are made of, including silicon cells, glass, aluminum, and wiring, and how these materials affect efficiency and durability.

Get Price

What are solar panels made of and how are they made?

Solar panels are made of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under an anti-reflective glass cover. The photovoltaic effect

Get Price

How Are Solar Panels Made: Ultimate Guide

What Are Solar Panels Made Of Solar panels are made of photovoltaic cells, also known as PV cells. They use semiconductor materials,

Get Price

How do solar panels work? Solar power explained

Solar panels work by converting incoming photons of sunlight into usable electricity through the photovoltaic effect.

Get Price

How Are Solar Panels Made? (2025) | ConsumerAffairs®

Want to know how solar panels are made? Learn the manufacturing process step by step and find out how environmentally friendly

Get Price

How Are Solar Panels Made? – Forbes Home

Solar panels are made of various parts that work together to create electricity from sunlight. PV cells, typically made of crystalline silicon (c-Si) or cadmium telluride (CdTe), are

Get Price

What are solar panels made of and how are they made?

Solar power has entered the mainstream as the world''s cheapest energy source, leaving many people wondering how solar photovoltaic cells can be so efficient and

Get Price

How Are Solar Panels Made?

Learn how solar panels are made, where the raw materials are mined in the U.S., and how silica is transformed into a useable solar cell.

Get Price

How are Solar Panels Made? – Solar Manufacturing

Solar panels are made by refining silicon, forming it into wafers, assembling photovoltaic cells, and then connecting cells into panels. This

Get Price

Solar Photovoltaic Cell Basics

Solar cells made out of silicon currently provide a combination of high efficiency, low cost, and long lifetime. Modules are expected to last for 25 years or more,

Get Price

What Are Solar Panels Made Of and How They Are Made

Solar panels have revolutionized how we harness energy, converting sunlight into electricity power providing a sustainable and eco-friendly alternative to fossil fuels. But have you ever

Get Price

3 FAQs about [What are solar panels made of ]

Where are solar panels made?

Based in Tajpur, Sabarkantha, Gujarat, the company manufactures both monocrystalline and polycrystalline solar panels at its 25,375-square-meter, 200 MW-capacity manufacturing facility. The distinction between these lies in their solar cell composition, affecting efficiency and appearance.

How are solar panels made?

The process starts with extrusion, where aluminum is pushed through a die to create the bracket’s shape. This method allows for intricate profiles and adjustable features. The brackets are designed to accommodate the specific dimensions and angle requirements of the solar panels.

Where are Panasonic solar panels made?

Panasonic solar panels are manufactured in the U.S. and Malaysia, while Mission Solar is manufactured strictly in the U.S. Jinko Solar, a less expensive solar panel company than Panasonic or Mission Solar, manufactures their solar panels in China. While another lesser-known company, Candian Solar, manufactures its panels in Canada.

More related information

-

What are solar panels made of

What are solar panels made of

-

What solar panels can I use with an 8W water pump inverter

What solar panels can I use with an 8W water pump inverter

-

What kind of solar panels are solar panels

What kind of solar panels are solar panels

-

What is the appropriate cost of solar panels for photovoltaic projects

What is the appropriate cost of solar panels for photovoltaic projects

-

What are the brands of container solar panels

What are the brands of container solar panels

-

What are the manufacturers of solar panels for communication base stations

What are the manufacturers of solar panels for communication base stations

-

What types of solar panels are there in photovoltaic modules

What types of solar panels are there in photovoltaic modules

-

What shape are the edges of solar panels

What shape are the edges of solar panels

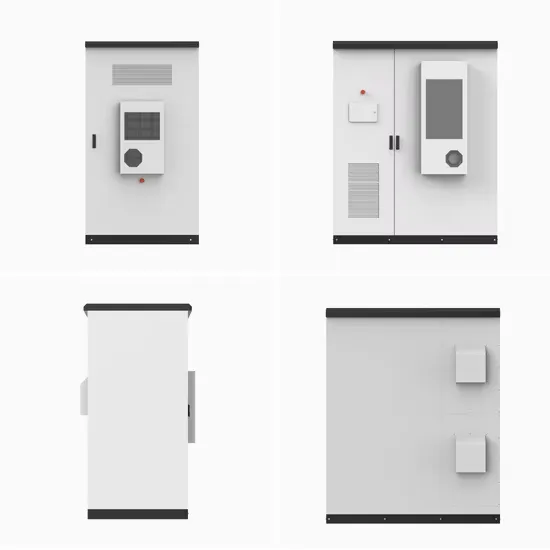

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

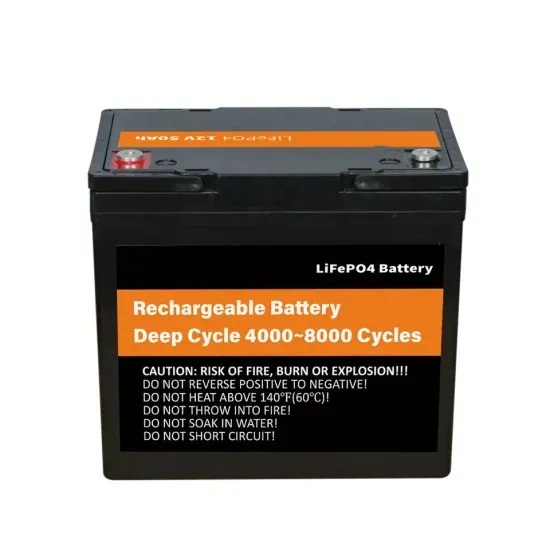

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.