The internal resistance of the energy storage charging pile is 0

Internal resistance and voltage of energy storage charging pile. During charging, the fluctuation of parameters of charging equipment, such as internal temperature, charging pile input/output

Get Price

Energy storage charging pile refers to the energy storage battery of differ ent capacities added a c-cording to the practical need in the traditional charging pile box.

Get Price

(PDF) The structure design of mobile charging piles

According to the application requirements of mobile charging piles, CATIA software was used to model the structure, of which strength and reliability were analysed

Get Price

Research on the contribution of technological innovation

Overall, this study contributes to the understanding of the charging pile industry''s technological innovation efficiency and provides valuable recommendations for policymakers

Get Price

Energy Storage Charging Pile: The Game-Changer in EV Charging

Let''s break down the magic behind energy storage charging piles without the engineering jargon: These aren''t your grandpa''s charging stations. Check out what they bring

Get Price

Understanding the Charging Pile: The Future of Electric Vehicle

Although "charging pile" and "charging station" are occasionally used interchangeably, they describe different ideas. A charging pile is the basic component of an

Get Price

The role of the heat dissipation network for energy storage charging piles

The primary objective is to explore and realize the design optimization of the shell structure of the high-voltage control box, aiming to effectively mitigate the temperature rise in internal

Get Price

Internal material of energy storage charging pile

Energy Storage Capacity Configuration of Integrated Charging To improve the utilization efficiency of photovoltaic energy storage integrated charging station, the capacity of

Get Price

Internal resistance of new energy storage charging pile

What is energy storage charging pile management system? Based on the Internet of Things technology,the energy storage charging pile management system is designed as a three-layer

Get Price

What are the energy storage charging piles? | NenPower

Energy storage charging piles represent a transformative leap in the energy landscape, particularly as nations strive for sustainable

Get Price

(PDF) Research on energy storage charging piles based on

Aiming at the charging demand of electric vehicles, an improved genetic algorithm is proposed to optimize the energy storage charging piles optimization scheme. Firstly, the

Get Price

Structural principle of power supply line of energy storage

This article aims to deeply explore the internal structure and working principles of two charging piles widely used in our country''''s market--AC charging piles and DC charging

Get Price

Internal disassembly method of energy storage charging pile

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging, discharging,

Get Price

New energy storage charging pile structure

What is energy storage charging pile management system? Based on the Internet of Things technology, the energy storage charging pile management system is designed as a three-layer

Get Price

Understanding the Charging Pile: The Future of

Although "charging pile" and "charging station" are occasionally used interchangeably, they describe different ideas. A charging pile is the

Get Price

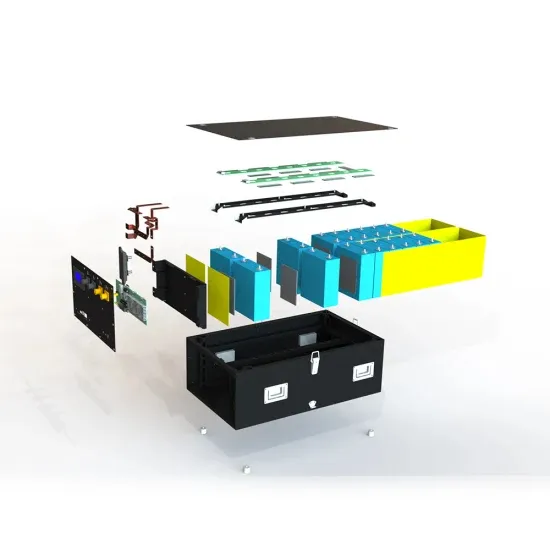

Energy storage charging pile structure diagram

In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to build a new EV charging pile with integrated charging,

Get Price

Energy Storage Charging Pile: The Game-Changer in EV

Let''s break down the magic behind energy storage charging piles without the engineering jargon: These aren''t your grandpa''s charging stations. Check out what they bring

Get Price

52a energy storage charging pile

This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and manage-ment of the energy storage structure of charging pile...

Get Price

Energy Storage Charging Pile Management Based on Internet of

The functions such as energy storage, user management, equipment management, transaction management, and big data analysis can be implemented in this

Get Price

Principle of internal resistance detection of energy storage

The electric vehicle charging pile can realize the fast charging of electric vehicles, and the battery of the electric vehicle can be used as the energy storage element, and the electric energy can

Get Price

Energy storage charging pile internal resistance 27 5

The piles are 9m long and are embedded in soft clay with cohesion 30kN/m2. Bearing resistance may be neglected for the piles. Adhesion factor is 0.6. Determine the ultimate load capacity of

Get Price

Energy storage charging pile frame structure

New energy storage charging pile structure design drawing New energy storage charging pile structure design drawing; excess demand charges, centralized energy storage and on-site

Get Price

(PDF) The structure design of mobile charging piles

According to the application requirements of mobile charging piles, CATIA software was used to model the structure, of which strength and

Get Price

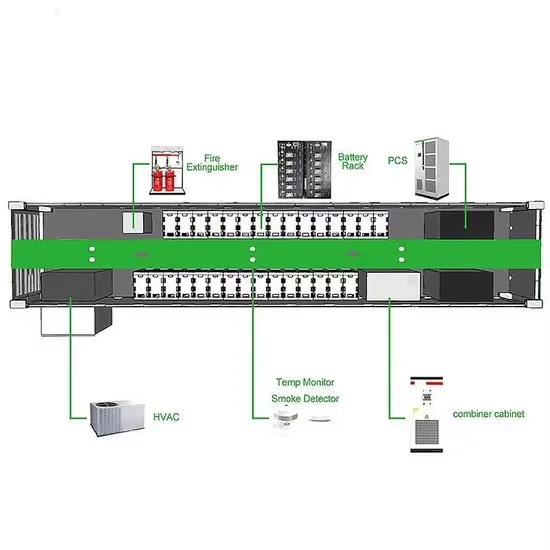

Internal structure diagram of energy storage charging pile group

Structure diagram of the Battery Energy Storage System (BESS), as shown in Figure 2, consists of three main systems: the power conversion system (PCS), energy storage system and the

Get Price

ENERGY STORAGE CHARGING PILE INTERNAL

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

Get Price

Structure comparison principle of energy storage charging pile

This paper proposes an energy storage pile power supply system for charging pile, which aims to optimize the use and management of the energy storage structure of charging pile and

Get Price

What are the energy storage charging piles? | NenPower

Energy storage charging piles represent a transformative leap in the energy landscape, particularly as nations strive for sustainable progression. Fundamentally, these

Get Price

Structural principle of power supply line of energy storage

Design of Energy Storage Charging Pile Equipment The main function of the control device of the energy storage charging pile is to facilitate the user to charge the electric vehicle and to

Get Price

Principle of internal resistance detection of energy storage charging pile

The electric vehicle charging pile can realize the fast charging of electric vehicles, and the battery of the electric vehicle can be used as the energy storage element, and the electric energy can

Get Price

6 FAQs about [The internal structure of the charging pile energy storage]

What are the components of a charging pile?

A charging pile comprises several components which are crucial for its operational functionality and security features: Power Supply Module – Converts and stabilizes the energy from the grid. Charge Controller – Smartly operates the voltage, current, and communication functions between the vehicle and the charging pile.

What is the difference between charging pile and charging station?

Although “charging pile” and “charging station” are occasionally used interchangeably, they describe different ideas. A charging pile is the basic component of an electric power infrastructure that allows electricity to flow to the vehicle.

What is an EV charging pile?

An EV charger or charging pile is a unit intended for supplying electric energy to an electric vehicle that requires charging in order to increase its stored energy. They act as intermediaries between the power grid and an electric vehicle (EV), controlling the current and voltage supply to ensure that charging is done efficiently and safely.

What are the charging pile instructions?

Instructions for Charging Pile-V1.3.0: Power Output Mode: Can be switched between intelligent mode and priority mode. In intelligent mode, the charging pile power is equally distributed between the two vehicle connectors.

Why is it important to maintain the charging pile?

The importance of maintaining charging piles lies in the fact that influences by the changeable environment and ageing inner parts can cause various faults. Regular examination and maintenance are necessary during both product storage and using processes.

What is the installation distance of the charging pile?

The minimum installation distances for the charging pile are: no less than 700 mm from the back door to the wall, and no less than 500 mm from the side face to the wall. (5) The canopy is built together with the charging pile. (6) This installation method is just a sample for reference.

More related information

-

Mobile energy storage charging pile price standard

Mobile energy storage charging pile price standard

-

Energy storage power station charging pile cost

Energy storage power station charging pile cost

-

Energy Storage Charging Pile Virtual Power Plant

Energy Storage Charging Pile Virtual Power Plant

-

Haiti s photovoltaic charging pile energy storage policy

Haiti s photovoltaic charging pile energy storage policy

-

Venezuela photovoltaic charging pile energy storage efficiency

Venezuela photovoltaic charging pile energy storage efficiency

-

Gabon charging pile energy storage cabinet

Gabon charging pile energy storage cabinet

-

Panama Photovoltaic Charging Pile Energy Storage System

Panama Photovoltaic Charging Pile Energy Storage System

-

Support customized charging pile energy storage equipment

Support customized charging pile energy storage equipment

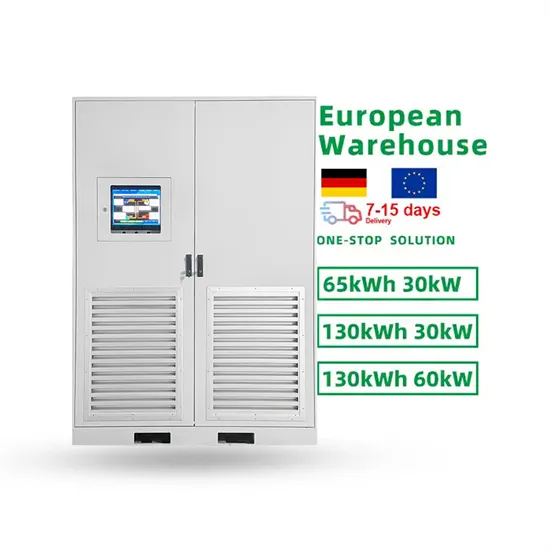

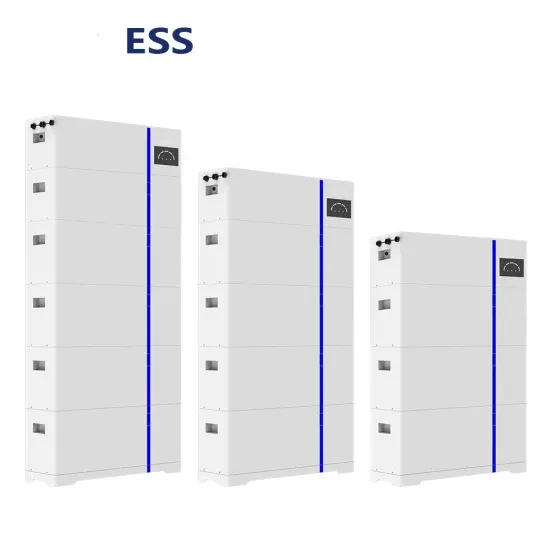

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

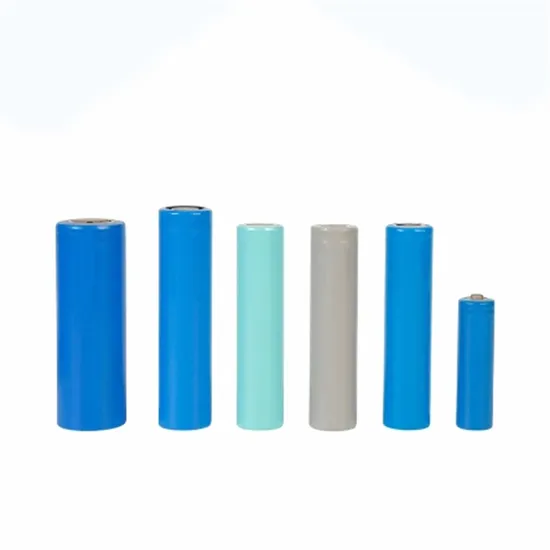

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.