What Does an Inverter Do

What Does an Inverter Do ? Inverters are also called AC Drives, or VFD (variable frequency drive). They are electronic devices that can turn DC (Direct Current)

Get Price

CSM_Inverter_TG_E_1_1

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses

Get Price

Medium & High Voltage Drives

Our Medium & High Voltage drives are designed to improve the overall flexibility and efficiency of the plant, achieving significant, long-term cost savings by reducing energy consumption.

Get Price

A Simplified Synchronous Pulse-Width Modulation Method

A. A. K. Rathore, J. Holtz and T. Boller, "Optimal pulse width modulation of multilevel inverters for low switching frequency control of medium voltage high power industrial AC drives", Energy

Get Price

MVW3000

Developed with CHB (Cascaded H-Bridge) technology with associated high reliability power cells, in order to serve high power motors at all voltage levels between 1 kV and 13.8 kV AC.

Get Price

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power

Get Price

High-Power Converters and AC Drives: A Comprehensive

Explore the role of high-power converters and Darwin Motion AC drives in industrial applications. Learn how these technologies work together to improve energy efficiency, motor

Get Price

MVW3000

Developed with CHB (Cascaded H-Bridge) technology with associated high reliability power cells, in order to serve high power motors at all voltage levels

Get Price

PWM Current Source Inverters

Abstract This chapter focuses on the pulse-width-modulated (PWM) current source inverter (CSI) technologies for high-power medium voltage drives. It analyses three modulation

Get Price

AC Drives (Medium Voltage)

Ideal inverters for facilities using a large number of small-to-medium capacity motors. Applications: steel, non-ferrous metals, paper, general industrial, etc.

Get Price

Corporate_2009

In the early 1990''s we were pioneers in high speed technology for gas compression applications. Today, our R&D activities are taking this technology even further, developing power electronic

Get Price

Dual-Inverter Fed Induction Motor Drive using Optimal Pulse

Abstract— This paper presents the synchronous optimal pulse width modulation (SOP) for control of medium–voltage induction motor drives using dual inverters at low switching frequency. In

Get Price

Variable-frequency drive

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable

Get Price

AC Drives (Medium Voltage)

This is Fuji Electric''s lineup of medium-voltage inverters. With models compatible with a wide range of capacities, our inverters can be used in a variety of

Get Price

Multilevel vs Two-Level Inverters | SpringerLink

To resolve the above-mentioned problems, a new technology of inverters called Multilevel Inverters (MLI) has been introduced employing combination of switches and DC

Get Price

AC Drives (Medium Voltage)

This is Fuji Electric''s lineup of medium-voltage inverters. With models compatible with a wide range of capacities, our inverters can be used in a variety of applications including steel,

Get Price

AC Variable Speed Drives – Inverters

Hitachi''s high-performance AC Variable Speed Drives-Inverters, and adjustable speed motor control inverters are developed after years of research to offer AC drives with enhanced

Get Price

Medium Voltage Inverter

The inverters of this series implement energy feedback at full power using PWM controllable rectifier, and the maximum feedback power of the inverters is equal to the maximum output

Get Price

Performance improvements of power converters for high power

Both converters effectively alleviate power quality and harmonic profile within the standard limits.

Get Price

Inverter and Multilevel Inverter

Some medium voltage motor drives and utility applications require medium voltage. The multi-level inverter has been introduced since 1975 as an alternative in high power and medium

Get Price

PWM Current Source Inverters

This chapter focuses on the pulse-width-modulated (PWM) current source inverter (CSI) technologies for high-power medium voltage drives. It analyses three modulation

Get Price

Evolution of Very-High-Power (>15-MW) Medium-Voltage Drives

Abstract: Very-high-power adjustable-speed motor applications above 15 MW historically used load-commutated inverter drives coupled to designed-for-purpose synchronous motors.

Get Price

Synchronous Optimal Pulsewidth Modulation for High-Power AC Motor

Electric vehicles require high-power machines, so reducing power loss becomes crucial. Compared to space vector modulation, synchronous optimal pulsewidth modulation

Get Price

High-Power Converters and AC Drives: A

Explore the role of high-power converters and Darwin Motion AC drives in industrial applications. Learn how these technologies work together

Get Price

What Is an Inverter Duty Rated Motor?

Over years of use in the motor industry, the term "inverter duty" for motor ratings has become watered down. Whenever someone refers to an inverter duty motor, they are

Get Price

Inverter Rated AC Motors: The Best Choice for High-Performance

Inverter rated AC motors enhance performance through improved energy efficiency, better speed control, reduced noise, and extended lifespan. Each of these factors contributes

Get Price

More related information

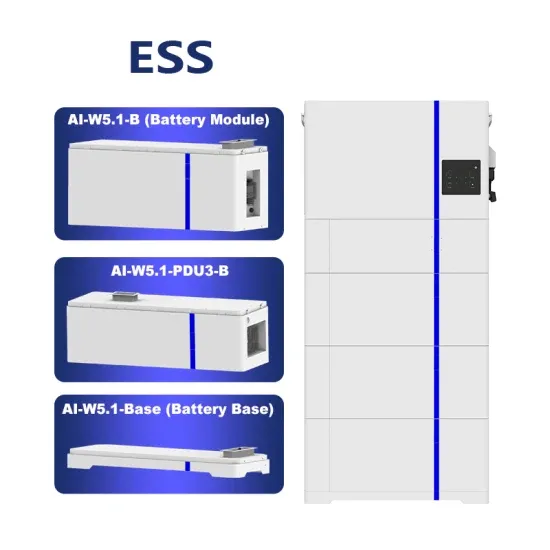

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Serbia high power inverter

Serbia high power inverter

What is the maximum power of a 12v high power inverter

What is the maximum power of a 12v high power inverter

Inverter AC Motor

Inverter AC Motor

Liechtenstein inverter high power brand

Liechtenstein inverter high power brand

Inverter brand high power

Inverter brand high power

Introduction to High Power Inverter

Introduction to High Power Inverter

Huawei inverter 2kw high power

Huawei inverter 2kw high power

Whether the motor drives the inverter power

Whether the motor drives the inverter power