Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get Price

Learn About High vs. Low Frequency Inverters: Which

This is followed by a high-frequency transformer to step up the voltage, followed by a filter to rectify the voltage to high-voltage DC, and

Get Price

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get Price

voltage

You need a more expensive ("pure sinewave") inverter to get a more accurate 50 Hz. The fact that you the frequency isn''t exactly 50 Hz is only a problem with devices that rely

Get Price

High frequency effects in inverter-fed AC electric machinery

"Steep voltage pulses" means, that the wave propagation time between inverter and motor on the motor cable is in THE SAME ORDER OF MAGNITUDE as the time for voltage build up.

Get Price

What is the difference between a low frequency inverter and a

Low-Frequency Inverter: Operates at a lower frequency, typically around 50Hz or 60Hz. Because its frequency is close to that of utility power, it is suitable for applications

Get Price

Power Frequency Inverter vs High-Frequency Inverter

A power frequency inverter generally refers to an inverter with an output frequency of 50 Hz or 60 Hz. Its operating principle is to transform DC power into AC power with the

Get Price

50hz To 60hz Frequency Converter Circuit Diagram

China 50hz To 60hz 15kw Chinese Vfd High Quality 3 Phase Frequency Converter Manufacturer And List Lianying Enterprise 100 Kva

Get Price

Pure Sine Wave Inverters

While an inverter can produce different waveforms, a pure sine wave output is preferable because many electrical products are designed to work best with a sine wave AC power source. A high

Get Price

What is the difference between a low frequency inverter and a high

Low-Frequency Inverter: Operates at a lower frequency, typically around 50Hz or 60Hz. Because its frequency is close to that of utility power, it is suitable for applications

Get Price

High frequency vs low frequency pure sine wave

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few

Get Price

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get Price

Multiplus II: What is the tolerance of the input frequency range set

I wonder what will be the behaviour of the Multiplus II if I set it to frequency 50Hz (the first option), what will be the frequency tolerance accepted by the inverter and at what

Get Price

3 Things To Know About Frequency Converter

This can occur when one voltage is in a non-sinusoidal waveform, causing it to become distorted. Devices such as frequency converters, which

Get Price

Understanding High-Frequency Inverters

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current

Get Price

Inverter design using high frequency

This can possible with the help of High Frequency Inverter; hence we have selected this project. We have used push pull convection and full bridge conversion topology.

Get Price

Understanding the Difference Between Low Frequency and High Frequency

In this article, we will examine the differences between low frequency or high frequency inverter. Both inverters have unique features and advantages and disadvantages,

Get Price

High Frequency Inverter Circuit

A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency,

Get Price

Understanding the Difference Between Low

In this article, we will examine the differences between low frequency or high frequency inverter. Both inverters have unique features and

Get Price

Frequency inverters

What''s a Frequency Inverter? Frequency inverter also called frequency converter, it is a power control conversion device to convert normal power supply (50Hz or 60Hz) to another

Get Price

10kv 355kw Inverter Frequency Converter 50Hz to 60Hz for Coal

10kv 355kw Inverter Frequency Converter 50Hz to 60Hz for Coal Mills and Forced Draft Fans, Find Details and Price about Frequency Inverter High/Medium Voltage from 10kv

Get Price

Can I Run the Motor Higher than 50Hz by Using a VFD?

Running an AC motor above its rated frequency using a Variable Frequency Drive (VFD) is often technically possible, but it requires a thorough

Get Price

Mains Frequency Converter Circuit Diagram

Introduction The device called the converter changes an unstable voltage frequency from a mains source into a stable one using quartz crystal

Get Price

High frequency vs low frequency pure sine wave inverter

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz.

Get Price

High-Frequency Inverters: From Photovoltaic, Wind, and

ac converter switches for operation at 120/240 V ac and 60/50 Hz. For 120-V ac output, the two ac–ac-converter filter capacitors are par-alleled (as shown in Fig. 29.12a), while for 240-V ac

Get Price

Homemade PCB EGS002 Full Sine Inverter Tutorial

How to make a full sinusoidal inverter using the EGS002 driver board. Supplied with 12V from a battery and output 230V AC at 50Hz with SINE wave and 500W.

Get Price

6 FAQs about [The inverter high frequency voltage becomes 50hz]

Do I need a 50 Hz inverter?

You need a more expensive ("pure sinewave") inverter to get a more accurate 50 Hz. The fact that you the frequency isn't exactly 50 Hz is only a problem with devices that rely on the 50 Hz to be accurate because they use the 50 Hz as a reference for timing.

How do high frequency power inverters convert DC to AC?

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency inverter circuit diagram

What is AC inverter frequency?

1. What is the frequency of AC inverter? An AC inverter frequency refers to the number of power signal fluctuations, typically measured in Hertz (Hz). In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second.

What is a high frequency inverter?

The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer-less inverter, or TL inverter.

What is the difference between high frequency and low frequency inverters?

Here is the major difference of them: Thanks to the heavy-duty transformer, low frequency inverters have much higher peak power capacity and reliability. The transformer handles higher power spikes with longer duration than high-frequency inverters when it comes to driving inductive loads such as electric motor, pump, compressor, air conditioners.

What is a standard inverter frequency?

In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second. This inverter frequency is essential for the proper functioning of electrical devices and systems, as it dictates the speed at which motors rotate, lights flicker, and electronic components operate. 2.

More related information

-

Bahamas high frequency inverter installation

Bahamas high frequency inverter installation

-

Inverter has high voltage

Inverter has high voltage

-

Medium frequency inverter output voltage

Medium frequency inverter output voltage

-

Mexico high voltage inverter

Mexico high voltage inverter

-

What is the voltage of a 96V household power frequency inverter

What is the voltage of a 96V household power frequency inverter

-

Saudi Arabia high voltage inverter manufacturer

Saudi Arabia high voltage inverter manufacturer

-

High frequency inverter crystal

High frequency inverter crystal

-

Weak current to high voltage inverter

Weak current to high voltage inverter

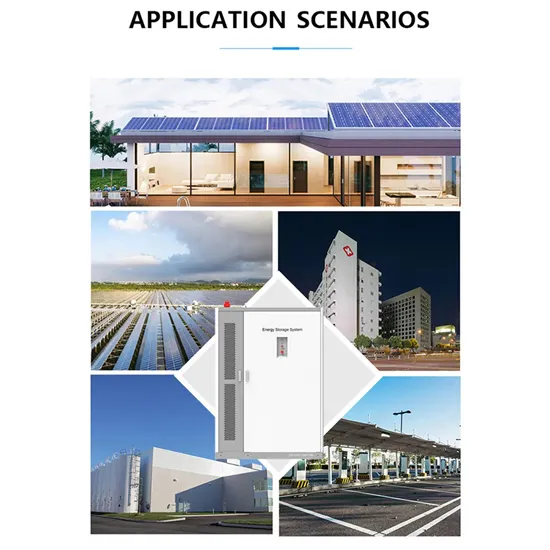

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

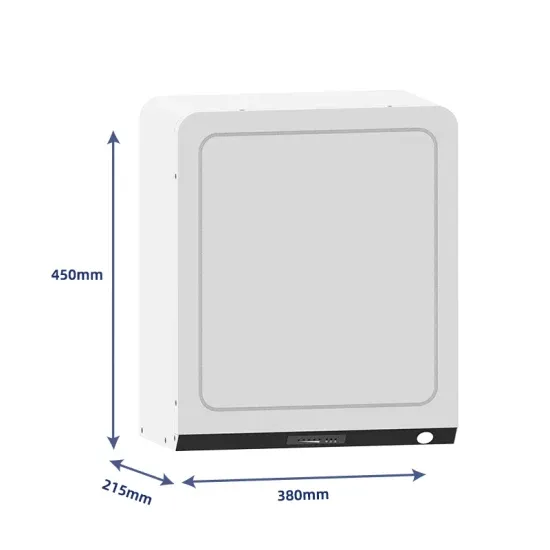

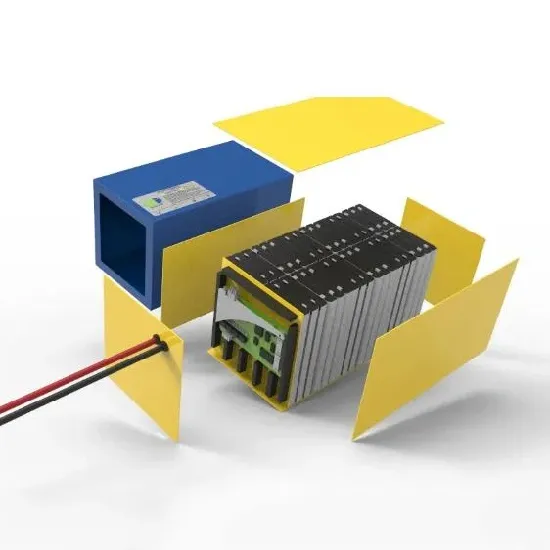

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.