From Quantity to Quality: The Challenge of Ramping up Domestic

The quality of Solar Modules is declining. This edition talks about the why and how to tackle this growing concern!

Get Price

Most solar assets have significant quality issues, says HelioVolta

20 hours ago· HelioVolta analysis says bad wiring and connections are the most common source of significant problems.

Get Price

India''s Solar Module Surge: SBI Warns of Oversupply Amid US Export

India''s solar module production has surged to 100 GW, but a report by SBI Capital Markets warns of potential oversupply risks. With the US reducing incentives for solar projects,

Get Price

Module reliability scorecard reveals widespread quality risk

The scorecard summarizes the results of extended reliability testing of commercially available PV modules, designed to expose any weaknesses that may show up in the field after

Get Price

Failure Rates for PV Panels Are Climbing

Concerns over PV panel quality are on the rise. Inspectors are finding higher defect rates in solar panels manufactured in China as attempts to cut costs prompt the use of

Get Price

Module quality is suffering as PV producers cut costs

But we''re seeing that manufacturers have tried to remove materials, remove costs from those modules, to cut their losses, and that presents reliability risks.

Get Price

How solar production affects power quality

How does the addition of a photovoltaic system affect the power quality of an electrical installation? Frankly, it depends on the details of the

Get Price

Most solar assets have significant quality issues, says HelioVolta – pv

20 hours ago· HelioVolta analysis says bad wiring and connections are the most common source of significant problems.

Get Price

From Quantity to Quality: The Challenge of Ramping up Domestic Module

The quality of Solar Modules is declining. This edition talks about the why and how to tackle this growing concern!

Get Price

Module reliability scorecard reveals widespread quality risk – pv

The scorecard summarizes the results of extended reliability testing of commercially available PV modules, designed to expose any weaknesses that may show up in the field after

Get Price

India has potential to lead solar PV exports to US, says IEEFA/JMK

Between fiscal years 2022 and 2024, India increased its import of solar modules 23-fold, primarily to the US, says IEEFA and JMK Research.

Get Price

Exports of photovoltaic equipment on the rise

Its products, especially solar panels and lithium batteries, are competitive in the global market with low prices and high quality, and relevant companies have

Get Price

Quality Control in Solar Panel Manufacturing: A Guide

Why is quality control in a solar panel production line important? Quality control ensures the PV panels manufacturers produce are reliable,

Get Price

Top solar modules in reliability, quality and performance testing

The Renewable Energy Test Center (RETC) has released its 2025 PV Module Index, assessing solar module reliability, quality, and performance across industry

Get Price

50% of Solar Module Come from China: US Solar

Domestically-manufactured modules accounted for approximately 15% of the US market in 2023, with First Solar accounting for about two-thirds

Get Price

Introduction to photovoltaic modules and common 21 quality

Cross cracking can cause wrinkles and debris to cause the failure of photovoltaic cells, and the power attenuation of modules directly affects the performance of photovoltaic

Get Price

India''s Solar PV Exports Soar 23-Fold Amid Strong U.S.

In a significant milestone for India''s renewable energy sector, solar photovoltaic (PV) module exports have surged over 23-fold from Fiscal Year (FY) 2022 to FY2024,

Get Price

Solar PV Module Quality Concerns Still Exist for Developing World

Conversations with solar industry executives from across the value chain reveal concerns about low-quality materials being used in the manufacturing of solar modules, and

Get Price

Module reliability scorecard reveals widespread

The Module Reliability Scorecard, published annually by PV module testing laboratory Kiwa-PVEL, released its 11 th edition today. The scorecard

Get Price

Introduction to photovoltaic modules and common 21

Cross cracking can cause wrinkles and debris to cause the failure of photovoltaic cells, and the power attenuation of modules directly affects the

Get Price

The 2025 PV Module Manufacturing Quality Report

Common quality findings identified in these factories include insufficient training for the equipment operators, poor equipment conditions, material mishandling.

Get Price

Poor quality solar photovoltaic panels

The payback performance of a solar PV systems is based, besides FITs and irradiation, on the initial power output, power degradation and the lifetime of the pv module(s). Needless to say

Get Price

How to evaluate solar module PAN files (and why it

Production models rely on PAN files to capture the attributes of a module that will impact its performance. Having accurate module data in these

Get Price

What Happens When Low Quality, Unproven

The quality of PV modules and the materials used in them can be best assessed by evaluating their performance in the field.

Get Price

Module reliability scorecard reveals widespread

The scorecard summarizes the results of extended reliability testing of commercially available PV modules, designed to expose any weaknesses

Get Price

Navigating defects in next-generation PV modules

PV modules are generally performing well across the solar industry but recent results from leading test labs suggest that some forms of

Get Price

Failure Rates for PV Panels Are Climbing

Concerns over PV panel quality are on the rise. Inspectors are finding higher defect rates in solar panels manufactured in China as attempts

Get Price

Solar PV Module Quality Risks

There''s a need for awareness on the increasing quality issues seen in PV modules. It''s essential to address these issues on time, preferably before the project is installed, to ensure optimal

Get Price

4 FAQs about [Exported photovoltaic modules have poor quality]

Why choose our photovoltaic module manufacturing equipment?

Our photovoltaic module manufacturing equipment are the result of our research and experience, but above all of our ongoing consultation with our customers. This means the product is specifically made-to-measure to their requests and needs, assuring a very flexible operating method when defining the order and during the production process.

Why do PV modules break a lot?

These increased breakage rates have been seen in the field already in recent years, and the move to larger module formats, made with thinner glass, is one part of the problem. But it also comes down to cost cutting efforts as manufacturers look to cut back on material consumption in times of low prices for PV components.

What are the biggest concerns for the PV industry in 2025?

But this stage of the test also demonstrated one of the biggest concerns for the PV industry in 2025, with a pronounced increase in module breakage. Cracked module glass, broken frames, and other issues such as junction box damage all saw an increase.

Does hail affect PV module performance?

Modules tested for this year’s scorecard revealed minimal performance loss following hail and other mechanical stress test sequences – potentially a sign of improvement on cell cracking that has long been seen a big risk to PV module performance in the field.

More related information

-

Photovoltaic modules exported to Pakistan

Photovoltaic modules exported to Pakistan

-

Are all photovoltaic modules exported

Are all photovoltaic modules exported

-

How many photovoltaic modules are exported from China to Europe

How many photovoltaic modules are exported from China to Europe

-

How much are North Korea s photovoltaic modules exported

How much are North Korea s photovoltaic modules exported

-

Austria double-glass photovoltaic modules

Austria double-glass photovoltaic modules

-

Monocrystalline silicon lightweight flexible photovoltaic modules

Monocrystalline silicon lightweight flexible photovoltaic modules

-

American double-glass photovoltaic modules

American double-glass photovoltaic modules

-

Cameroon quality photovoltaic energy storage system

Cameroon quality photovoltaic energy storage system

Commercial & Industrial Solar Storage Market Growth

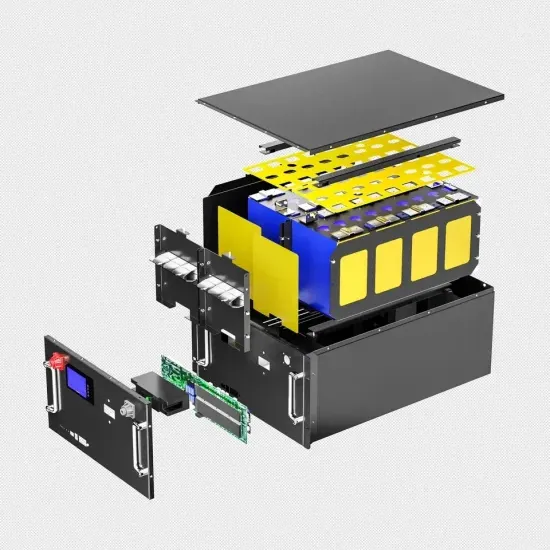

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.