Phase change material-based thermal energy storage

Phase change material (PCM)-based thermal energy storage significantly affects emerging applications, with recent advancements in

Get Price

Facile Ester-based Phase Change Materials

This approach greatly improves temperature regulation, enhances battery safety, and boosts operational efficiency, highlighting the immense

Get Price

Thermal energy storage performance, application and challenge of phase

Phase change material (PCM) has critical applications in thermal energy storage (TES) and conversion systems due to significant capacity to store and release heat. The

Get Price

Investigation on heat transfer enhancement of phase change

Phase change material (PCM), such as paraffin wax, has attracted extensive attention in the field of battery thermal energy storage (BTES) system. However, the latent

Get Price

What role do phase-change materials play in battery

When the battery generates heat, the PCM melts and stores this energy as latent heat, effectively cooling the battery. Unlike active cooling

Get Price

Optimization method of phase change energy storage device for

This paper focuses on optimizing the structure of a phase change heat exchanger in a phase change energy storage device to improve its performance. A basic design of the phase

Get Price

Rate capability and Ragone plots for phase change thermal

We show how phase change storage, which acts as a temperature source, is analogous to electrochemical batteries, which act as a voltage source. Our results illustrate

Get Price

Phase Change Technology: The Future of Energy Storage

These systems use materials that absorb/release heat during phase transitions (think solid-to-liquid), offering a clever solution to renewable energy''s "I only work when the sun shines"

Get Price

Facile Ester-based Phase Change Materials Synthesis for Enhanced Energy

This study synthesizes seven ester-based phase change materials (PCMs), significantly broadening their phase change temperature range while exhibiting excellent

Get Price

Innovative flexible multifunctional phase change materials for

Abstract Phase change materials (PCM) offer significant advantages in battery thermal management (BTM) due to high energy storage, chemical stability, and zero-energy

Get Price

Flexible composite phase change material with enhanced

A flexible composite phase change material (FCPCM) reduces thermal contact resistance in battery thermal management systems (BTMSs), thereby improving heat transfer

Get Price

Research on electric vehicle BTMS using phase change material

To leverage the thermal absorption and release properties of PCM for improving both high and low temperature stability, as well as mitigating temperature fluctuations in

Get Price

Using Phase Change Materials For Energy Storage

Phase change materials are proving to be a useful tool to store excess energy and recover it later – storing energy not as electricity, but as

Get Price

Rate capability and Ragone plots for phase change thermal energy storage

We show how phase change storage, which acts as a temperature source, is analogous to electrochemical batteries, which act as a voltage source. Our results illustrate

Get Price

New Physical Model Aims to Boost Energy Storage Research

Engineers rely on computational tools to develop new energy storage technologies, which are critical for capitalizing on sustainable energy sources and powering

Get Price

Facile Ester-based Phase Change Materials Synthesis for

Facile Ester-based Phase Change Materials Synthesis for Enhanced Energy Storage Toward Battery Thermal Management Long Geng, Kaifeng Luo, Yixuan Lin, Guo Li, Yitong Cao,

Get Price

Toward high-energy-density phase change thermal storage

Conversely, NH 3 ''s remarkable H 2 storage capacity (17.7 wt%), energy density (3000 Wh kg −1), and safe storage properties, along with established handling practices, making it a

Get Price

Using Phase Change Materials For Energy Storage

Phase change materials are proving to be a useful tool to store excess energy and recover it later – storing energy not as electricity, but as heat. Let''s take a look at how the

Get Price

Facile Ester-based Phase Change Materials Synthesis for Enhanced Energy

This approach greatly improves temperature regulation, enhances battery safety, and boosts operational efficiency, highlighting the immense potential of the material in

Get Price

Facile Ester‐based Phase Change Materials Synthesis for Enhanced Energy

With the increasing demand for thermal management, phase change materials (PCMs) have garnered widespread attention due to their unique advantages in energy storage

Get Price

What is battery thermal management based on phase

At present, PCM has been widely used in many fields, such as active or passive cooling system used in space field, electronic device and

Get Price

What role do phase-change materials play in battery thermal

When the battery generates heat, the PCM melts and stores this energy as latent heat, effectively cooling the battery. Unlike active cooling systems (like Peltier elements or

Get Price

What is battery thermal management based on phase change

At present, PCM has been widely used in many fields, such as active or passive cooling system used in space field, electronic device and energy storage device as thermal

Get Price

Toward High-Power and High-Density Thermal Storage: Dynamic Phase

Advancements in thermal energy storage (TES) technology are contributing to the sustainable development of human society by enhancing thermal utilization efficiency,

Get Price

Performance optimization of battery cooling system based on phase

This work proposes a low energy consumption and low-cost thermal management method for battery ESS, and provides a simple and accurate model for the optimization of thermal

Get Price

Thermal energy storage

Thermal energy storage tower inaugurated in 2017 in Bozen-Bolzano, South Tyrol, Italy. Construction of the salt tanks at the Solana Generating Station,

Get Price

Biobased phase change materials in energy storage and thermal

Present-day solutions mainly comprise of non-renewable phase change materials, where cyclability and sustainability concerns are increasingly being discussed. In pursuit of

Get Price

An overview of phase change materials on battery application

Phase change materials (PCMs) bring great hope for various applications, especially in Lithium-ion battery systems. In this paper, the modification methods of PCMs and

Get Price

Experimental investigation on battery thermal management using phase

Thermal management is imperative for regulating battery temperature during operation. In this paper, lithium iron phosphate batteries were taken to experimentally

Get Price

Research on electric vehicle BTMS using phase change material energy

To leverage the thermal absorption and release properties of PCM for improving both high and low temperature stability, as well as mitigating temperature fluctuations in

Get Price

6 FAQs about [Battery phase change energy storage]

How do phase change materials store energy?

Unlike batteries or capacitors, phase change materials don’t store energy as electricity, but heat. This is done by using the unique physical properties of phase changes – in the case of a material transitioning between solid and liquid phases, or liquid and gas. When heat energy is applied to a material, such as water, the temperature increases.

What is phase change energy storage?

The phase change material must retain its properties over many cycles, without chemicals falling out of solution or corrosion harming the material or its enclosure over time. Much research into phase change energy storage is centered around refining solutions and using additives and other techniques to engineer around these basic challenges.

Can phase change material be used in active battery thermal management systems?

The incorporation of phase change material (PCM) within active battery thermal management systems (BTMS) is viewed as a promising direction for future advancements, yet an ideal structure for PCM implementation in BTMS to facilitate industrialization remains elusive.

Are phase change materials effective in thermal management of lithium-ion batteries?

The hybrid cooling lithium-ion battery system is an effective method. Phase change materials (PCMs) bring great hope for various applications, especially in Lithium-ion battery systems. In this paper, the modification methods of PCMs and their applications were reviewed in thermal management of Lithium-ion batteries.

Are phase change materials suitable for thermal energy storage?

Phase change materials are promising for thermal energy storage yet their practical potential is challenging to assess. Here, using an analogy with batteries, Woods et al. use the thermal rate capability and Ragone plots to evaluate trade-offs in energy storage density and power density in thermal storage devices.

How does phase change affect heat storage?

A wide variety of materials have been studied for heat storage through the phase change effect. Paraffin wax is perhaps one of the most commonly studied, thanks to its phase change occuring in a useful temperature range. However, its low thermal conductivity limits the rate at which energy can be exchanged, hampering performance.

More related information

-

Lithuania Phase Change Energy Storage System

Lithuania Phase Change Energy Storage System

-

Zimbabwe Phase Change Energy Storage Grid

Zimbabwe Phase Change Energy Storage Grid

-

Black Mountain Phase Change Energy Storage System

Black Mountain Phase Change Energy Storage System

-

Prices of phase change energy storage in Saudi Arabia

Prices of phase change energy storage in Saudi Arabia

-

Russian phase change energy storage system

Russian phase change energy storage system

-

Large-scale phase change energy storage

Large-scale phase change energy storage

-

Phase Change Energy Storage Microgrid

Phase Change Energy Storage Microgrid

-

Iraqi phase change energy storage system manufacturer

Iraqi phase change energy storage system manufacturer

Commercial & Industrial Solar Storage Market Growth

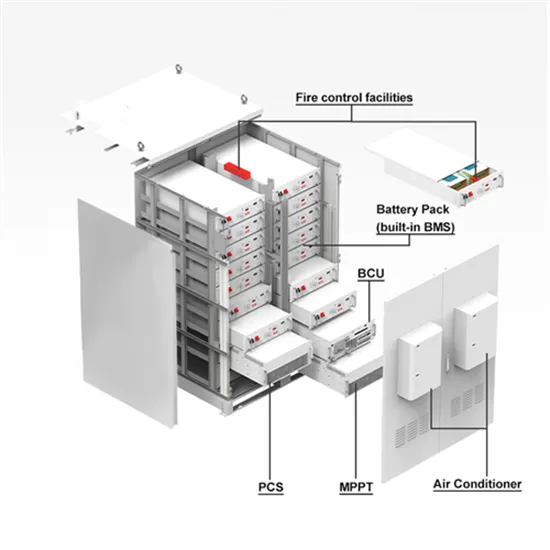

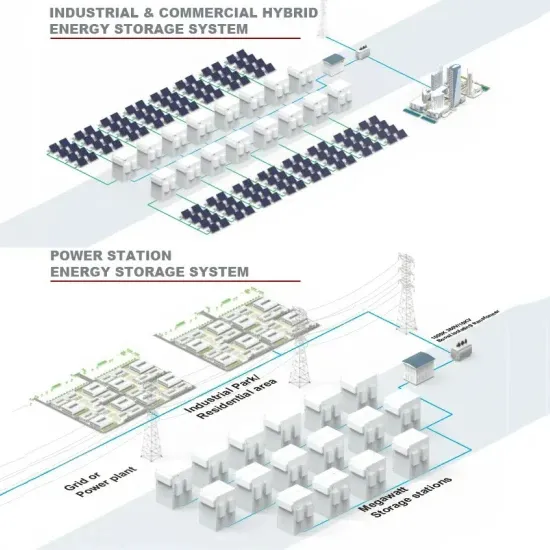

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.