NAS Battery: 20% lower cost for next-generation

The new ''advanced'' version of the sodium-sulfur (NAS) battery, first commercialised by Japanese industrial ceramics company NGK more

Get Price

An Evaluation of Energy Storage Cost and

To define and compare cost and performance parameters of six battery energy storage systems (BESS), four non-BESS storage technologies,

Get Price

Energy Storage Technology and Cost Characterization Report

Abstract This report defines and evaluates cost and performance parameters of six battery energy storage technologies (BESS) (lithium-ion batteries, lead-acid batteries, redox flow batteries,

Get Price

High and intermediate temperature sodium–sulfur batteries for energy

Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS). This review focuses solely on the progress, prospects and

Get Price

Calculation of the cost per kilowatt-hour of sodium-sulfur batteries

The cost of lithium-ion batteries per kWh decreased by 14 percent between 2022 and 2023. Lithium-ion battery price was about 139 U.S. dollars per kWh in 2023.

Get Price

Low Cost Sodium Sulfur Battery Shows Promise

Room-temperature sodium sulfur (RT-Na/S) batteries possess high potential for grid scale stationary energy storage due to their low cost and high

Get Price

Exclusive: sodium batteries to disrupt energy storage

According to GetFocus, achieving a cost of around $50/kWh is essential for BESS to be economically viable for grid-scale LDES in renewable

Get Price

Sodium-Ion Battery Vs. Lithium-Ion Battery: Which One is Better?

So, sodium has some significant advantages when it comes to availability and cost, but there are some key hurdles for adoption in EVs. Right now, it appears that sodium

Get Price

Sodium Sulfur Battery

The sodium-sulfur battery (Na–S) combines a negative electrode of molten sodium, liquid sulfur at the positive electrode, and β-alumina, a sodium-ion conductor, as the electrolyte to produce 2

Get Price

An Evaluation of Energy Storage Cost and

This paper defines and evaluates cost and performance parameters of six battery energy storage technologies (BESS)—lithium-ion

Get Price

Battery: Sodium Sulfur Battery System | United Nations Industrial

Sodium sulfur batteries produced by NGK Insulators Ltd. offer an established, large-scale energy storage technology with the possibility for installation virtually anywhere. With a wide array of

Get Price

sodium battery energy storage costs

Future Sodium Ion Batteries Could Be Ten Times Cheaper for Energy Storage Wyoming has 47 billion tons of mineable soda ash in the Green River basin. There would be hundreds of TWH

Get Price

Cost Projections for Utility-Scale Battery Storage: 2021

In order to differentiate the cost reduction of the energy and power components, we relied on BNEF battery pack projections for utility-scale plants (BNEF 2019, 2020a), which reports

Get Price

How Inexpensive Must Energy Storage Be for Utilities

High-temperature sodium-sulfur batteries cost $500/kWh, but with more development, their costs could fall by up to 75 percent by 2030,

Get Price

Research on sodium sulfur battery for energy storage

It works based on the electrochemical reaction between sodium and sulfur and the formation of sodium polysulfide and exhibits high power and energy density, temperature

Get Price

NAS Battery: 20% lower cost for next-generation sodium-sulfur tech

The new ''advanced'' version of the sodium-sulfur (NAS) battery, first commercialised by Japanese industrial ceramics company NGK more than 20 years ago,

Get Price

Utility-Scale Battery Storage | Electricity | 2024 | ATB | NREL

Base year installed capital costs for BESSs decrease with duration (for direct storage, measured in $/kWh) whereas system costs (in $/kW) increase. This inverse behavior is observed for all

Get Price

An Evaluation of Energy Storage Cost and Performance

To define and compare cost and performance parameters of six battery energy storage systems (BESS), four non-BESS storage technologies, and combustion turbines (CTs)

Get Price

Lithium-Ion Battery Pack Prices See Largest Drop Since 2017,

New York, December 10, 2024 – Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour,

Get Price

Energy storage costs

Informing the viable application of electricity storage technologies, including batteries and pumped hydro storage, with the latest data and analysis on costs and performance.

Get Price

Battery energy storage system

A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a type of energy storage technology that uses a

Get Price

High and intermediate temperature sodium–sulfur

Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS). This review focuses solely

Get Price

Energy Storage Cost and Performance Database

Additional storage technologies will be added as representative cost and performance metrics are verified. The interactive figure below presents results

Get Price

Exclusive: sodium batteries to disrupt energy storage market

According to GetFocus, achieving a cost of around $50/kWh is essential for BESS to be economically viable for grid-scale LDES in renewable energy applications. "That is the point

Get Price

Figure 1. Recent & projected costs of key grid

Meanwhile, the costs of pumped hydro storage are expected to remain relatively stable in the coming years, maintaining its position as the cheapest form – in terms of $/kWh –

Get Price

Energy Storage Cost and Performance Database

Additional storage technologies will be added as representative cost and performance metrics are verified. The interactive figure below presents results on the total installed ESS cost ranges by

Get Price

SODIUM SULPHUR (NAS) BATTERY FOR LARGE-SCALE

ed that FOM costs remain 1.5% of investment costs in 2020, 2030 and 2050. FOM costs by FCH JU McKinsey 2015 are calculated using FOM cos. s of 35 €/kW and the assumption of average

Get Price

Energy Storage Technology and Cost Characterization Report

Abstract This report defines and evaluates cost and performance parameters of six battery energy storage technologies (BESS) (lithium-ion batteries, lead-acid batteries, redox

Get Price

How Inexpensive Must Energy Storage Be for Utilities to Switch

High-temperature sodium-sulfur batteries cost $500/kWh, but with more development, their costs could fall by up to 75 percent by 2030, according to the International

Get Price

6 FAQs about [Sodium-sulfur battery energy storage cost per kilowatt-hour]

How much does a sodium-sulfur battery cost?

Figure 5.1. Example input values for annualized cost calculation for a sodium-sulfur battery. Using these inputs, the total net present value (NPV) of the total cumulative cost for the 1 MW/4 MWh storage system after tax, insurance, and other factors described is calculated to be just over $4 million, of which nearly 71 percent is CAPEX-based.

What is a sodium-sulfur battery?

Sodium-sulfur batteries are mature electrochemical energy storage devices with high-energy densities. According to Aquino et al. (2017a), they are primarily provided by a single Japanese-based vendor— NGK Insulators—which, to date, has installed 450 MW of the technology worldwide.

How are battery energy storage costs forecasted?

Forecast procedures are described in the main body of this report. C&C or engineering, procurement, and construction (EPC) costs can be estimated using the footprint or total volume and weight of the battery energy storage system (BESS). For this report, volume was used as a proxy for these metrics.

How much will sodium ion batteries cost in 2028?

Assuming a similar capex cost to Li-ion-based battery energy storage systems (BESS) at $300/kWh, sodium-ion batteries’ 57% improvement rate will see them increasingly more affordable than Li-ion cells, reaching around $10/kWh by 2028.

Are battery electricity storage systems a good investment?

This study shows that battery electricity storage systems offer enormous deployment and cost-reduction potential. By 2030, total installed costs could fall between 50% and 60% (and battery cell costs by even more), driven by optimisation of manufacturing facilities, combined with better combinations and reduced use of materials.

Do battery storage technologies use financial assumptions?

The battery storage technologies do not calculate levelized cost of energy (LCOE) or levelized cost of storage (LCOS) and so do not use financial assumptions. Therefore, all parameters are the same for the research and development (R&D) and Markets & Policies Financials cases.

More related information

-

Sodium-sulfur battery energy storage company

Sodium-sulfur battery energy storage company

-

How much does a battery energy storage cabinet cost in Ghana

How much does a battery energy storage cabinet cost in Ghana

-

How much does a Norwegian household energy storage battery cost

How much does a Norwegian household energy storage battery cost

-

Battery Energy Storage Cabinet Cost Plan and Process

Battery Energy Storage Cabinet Cost Plan and Process

-

How much does a large energy storage battery cost per watt

How much does a large energy storage battery cost per watt

-

How much does the Gambia smart energy storage battery cost

How much does the Gambia smart energy storage battery cost

-

Frequency regulation energy storage battery cost

Frequency regulation energy storage battery cost

-

How much does a lithium battery for energy storage cost in the Republic of South Africa

How much does a lithium battery for energy storage cost in the Republic of South Africa

Commercial & Industrial Solar Storage Market Growth

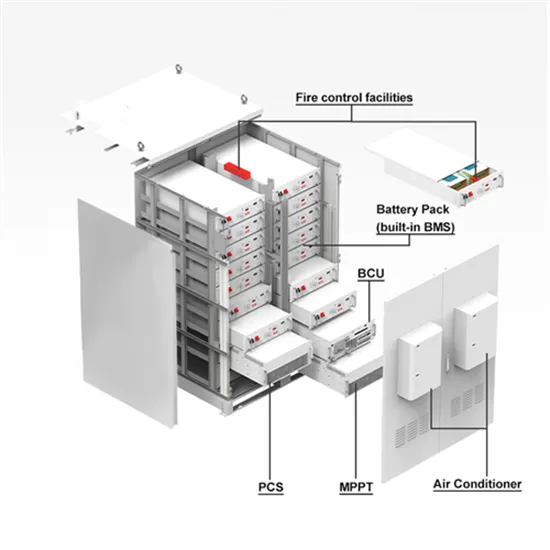

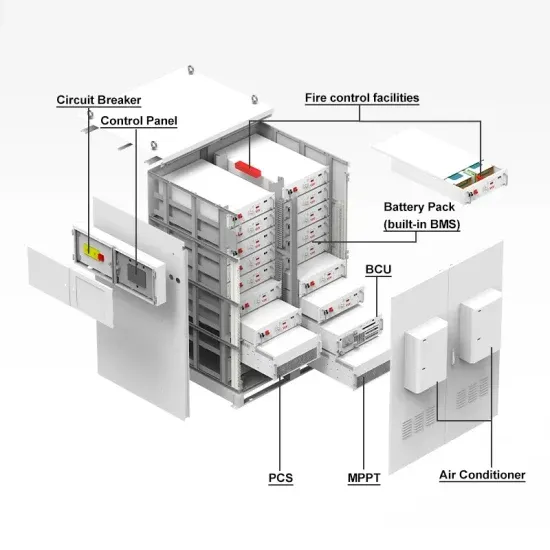

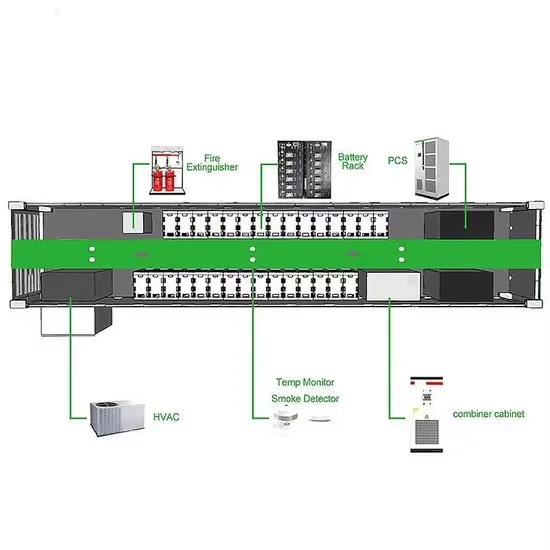

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.