What Is the Standard Thickness of Curtain Wall Photovoltaic Glass

The standard thickness of curtain wall photovoltaic glass typically ranges between 6 mm and 12 mm, depending on structural requirements and energy efficiency goals.

Get Price

Perforated Aluminum Panel Curtain Wall Shading System In The

⑶ ventilation characteristics of the application. Perforated aluminum as a building skin often used as an open external circulation system ventilation curtain wall, suitable for hot summer and

Get Price

First Proven Curtain Wall to Harness the Energy of the Sun

The polycrystalline PV panel consists of a piece of low-iron, tempered float glass. The solar cells are set between two layers of ethyl vinyl acetate (EVA) and laminated. The back of the ply or

Get Price

How to Install PV Curtain Walls and Solar Awnings?

This essay provides an overview of various photovoltaic (PV) curtain wall and awning systems, highlighting their components, structural designs, and key installation features. It covers point

Get Price

Curtain wall details with dimensions typical design

Curtain walls undergo rigorous testing to ensure they meet industry standards and performance requirements. Testing includes assessments for

Get Price

Solar Panel Thickness: What You Need to Know Before Buying

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get Price

Glass curtain wall system

The curtain wall method of glazing enables glass to be used in large, uninterrupted areas of a building envelope, creating consistent, attractive

Get Price

Solar Photovoltaic Glass Curtain Wall

Photovoltaic modules used as curtain wall panels and daylighting roof panels need to meet not only the performance requirements of photovoltaic modules, but also the three

Get Price

How Many Thickness of Aluminium Panel for

Generally, when aluminium curtain wall veneer serves as a wall panel, the thickness of panel does not need to be picky. There is a layer of exterior walls,

Get Price

What is a solar photovoltaic curtain wall and how is it

The performance requirements of the photovoltaic curtain wall (roof) system are related to the geographical and climatic conditions of the

Get Price

CHAPTER 15. FENESTRATION

In addition, curtain wall systems for commercial buildings may be structurally glazed, and the outdoor "framing" is simply rubber gaskets or silicone.

Get Price

Curtain Walls & Spandrels

Curtain walling refers to a non-structural cladding system made from fabricated aluminum, commonly used on the outer walls of tall multi-storey buildings. This lightweight material offers

Get Price

First Proven Curtain Wall to Harness the Energy of the Sun

The solar cells are set between two layers of ethyl vinyl acetate (EVA) and laminated. The back of the ply or the interior side of the panel can be laminated with a protective layer of film. Overall

Get Price

Curtain Walls: Uses and Functional Requirements

Infill Panels for Curtain Wall Systems Curtain wall infill panels, responsible for opaque areas, require specific characteristics to ensure

Get Price

1620UT Curtain Wall System Guide Specifications

References to tolerances for wall thickness and other cross-sectional dimensions of glazed curtain wall members are nominal and in compliance with AA Aluminum Standards and Data.

Get Price

4. Façade and Exterior Wall Covering System

4.2. Material Tests Except for natural stones and concrete, only materials, tested, listed with Civil De-fence and complying to the following sections shall be allowed on exterior facades, based

Get Price

PV Curtain Wall System

At present, there are two main technical modes of PV curtain wall: one is crystalline silicon curtain wall and the other is amorphous silicon curtain wall. Crystalline silicon curtain

Get Price

PV Curtain Wall System

At present, there are two main technical modes of PV curtain wall: one is crystalline silicon curtain wall and the other is amorphous silicon curtain

Get Price

Curtain Walls

The Solar Innova modules of photovoltaic integration technology used in the BIPV installations are multifunctional. That is, in addition to generating electricity,

Get Price

Glass curtain wall | Guardian Glass curtain glazing

The curtain wall method of glazing enables glass to be used in large, uninterrupted areas of a building envelope, creating consistent, attractive

Get Price

SECTION #084413 – ALUMINUM CURTAIN WALL SYSTEM

This section is based on the products of Solar Innovations, Inc., which is located at: 31 Roberts Road Pine Grove, PA 17963 Phone 800-618-0669; Fax 800-618-0743; Email:

Get Price

What is a solar photovoltaic curtain wall and how is it usable?

The performance requirements of the photovoltaic curtain wall (roof) system are related to the geographical and climatic conditions of the building. For example, in coastal

Get Price

It has high compression and tensile strength, low thermal conductivity, good water repellency and low water absorption, is crack resistant and requires little maintenance.,UET rock wool,rock

Get Price

Double skin curtain walls

Size and thickness: Our photovoltaic glass modules are produced with size and thickness in order to suit any architectural specification for any individual project.

Get Price

Solar Panel Thickness: What You Need to Know

Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

Get Price

6 FAQs about [Curtain wall solar panel thickness requirements]

What are the physical properties of photovoltaic curtain wall (roof) system?

The physical properties of the photovoltaic curtain wall (roof) system mainly include wind pressure resistance, water tightness, air tightness, thermal performance, air sound insulation performance, in-plane deformation performance, seismic requirements, impact resistance performance, lighting performance, etc.

What is solar photovoltaic curtain wall?

Solar photovoltaic curtain wall integrates photovoltaic power generation technology and curtain wall technology. It is a high-tech product. It is a new type of building material that integrates power generation, sound insulation, heat insulation, safety and decoration functions.

Which solar cells are used in photovoltaic curtain wall?

At present, crystalline silicon solar cells and amorphous silicon solar cells are mainly used in photovoltaic curtain wall (roofing) systems. Photovoltaic glass modules have different color effects depending on the type of product used.

What is a PV curtain wall?

The PV curtain wall is the most typical one in the integrated application of PV building. It combines PV power generation technology with curtain wall technology, which uses special resin materials to insert solar cells between glass materials and convert solar energy into electricity through the panels for use by enterprises.

What are the different types of PV curtain wall?

At present, there are two main technical modes of PV curtain wall: one is crystalline silicon curtain wall and the other is amorphous silicon curtain wall. Crystalline silicon curtain wall is a building material combining polycrystalline or monocrystalline silicon module array with the curtain wall.

Are photovoltaic curtain walls a good choice?

Gas with harmful effect and no noise is a kind of net energy and has good compatibility with the environment. However, due to the high price, photovoltaic curtain walls are now mostly used for the roofs and exterior walls of landmark buildings, which fully reflects the architectural features.

More related information

-

Marshall Islands non-standard photovoltaic curtain wall solar panel components polysilicon

Marshall Islands non-standard photovoltaic curtain wall solar panel components polysilicon

-

Cuban photovoltaic curtain wall solar panel manufacturer

Cuban photovoltaic curtain wall solar panel manufacturer

-

Belize Solar Panel Curtain Wall Sales

Belize Solar Panel Curtain Wall Sales

-

Israeli solar panel curtain wall

Israeli solar panel curtain wall

-

Solar panel curtain wall structure

Solar panel curtain wall structure

-

Solar panel curtain wall renovation and installation

Solar panel curtain wall renovation and installation

-

Integrated solar panel curtain wall

Integrated solar panel curtain wall

-

Solar panel curtain wall manufacturing company

Solar panel curtain wall manufacturing company

Commercial & Industrial Solar Storage Market Growth

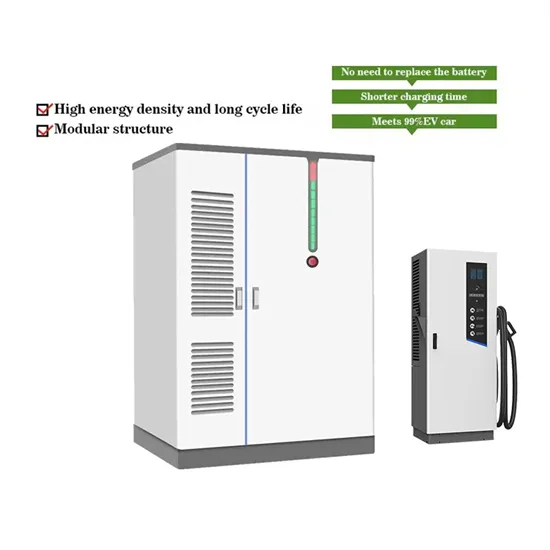

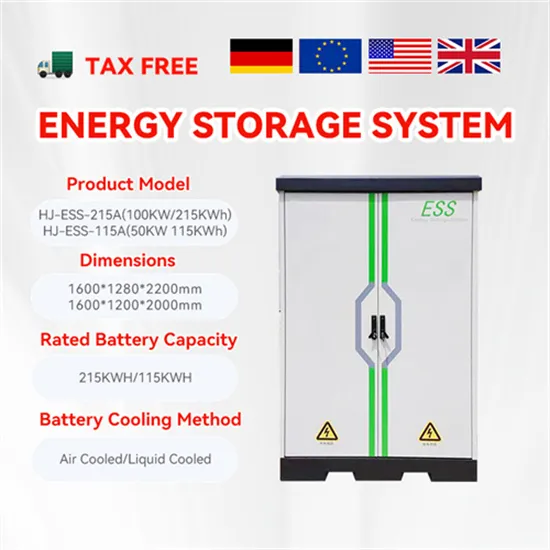

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

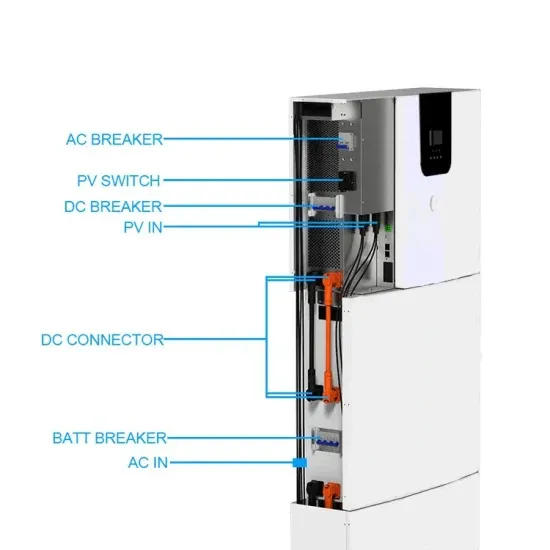

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.