SSZT070 Technical article | TI

Demand to reduce power losses will continue with the development of inverters that have higher power levels, especially as the number of motors per car increases, and trucks migrate to pure

Get Price

Photovoltaic Inverter Reliability Assessment

The first chapter discusses the motivation behind the research on assessing the reliability of PV inverters. The inverter power stage and controller design of the power converter used in this

Get Price

Why Power Conversion Systems Easily Scale to Megawatt

While semiconductor advances may push the inverter limit higher, overcoming the thermal and paralleling challenges within the market''s size/cost constraints remains a significant hurdle for

Get Price

Solar plateau?

Due to the application of micro inverters, each panel can have its own clipping losses. With string inverters, from the way I understand it, you would see the effect of the worst

Get Price

Mitigation technique of the SiC MOSFET gate voltage

Introduction The gate drive requirements of Silicon-Carbide (SiC) MOSFETs are similar to Silicon MOSFETs and IGBTs; however the superior switching capability combined with the specific

Get Price

Reducing Power Loss and Thermal Dissipation in SiC

Demand to reduce power losses will continue with the development of inverters that have higher power levels, especially as the number of motors per car increases, and trucks migrate to pure

Get Price

15-0713

Purpose counting purpose instrument of this experiment for X-ray, gamma-ray, is to familiarize beta-particle the student and with alpha-particle the Geiger-Mueller detection. counter.1 It uses

Get Price

Understanding Plateau Voltage in Power MOSFETs and Its

In power converters, motor drivers, and inverters, understanding the switching behavior of the MOSFET is critical. One important part of this behavior is the plateau voltage,

Get Price

Microinverter reaching a plateau way below its nominal output

This can be a variety of reasons including that the panels can''t produce any more or the inverter is maxed out. As an example, I see "peaks" when clouds come and go blocking out some of the

Get Price

Corrections of Original CFPREV Control in LCC-HVDC Links

Apart from the common factors, e.g., undue consumption of the inverter reactive power or increase of the DC current, that could limit the commutation failure suppressing capacity of the

Get Price

My solar production is starting to plateau (max out) mid day. I did

This can happen if the system capacity is calculated using the panel output power instead of the inverter output power.

Get Price

2022 Pleasure-Way Plateau Motorhome Go Power Automatic

2022 Pleasure-Way Plateau Motorhome rv transfer switch from Go Power. Product reviews from other Plateau Motorhome owners. Expert rv transfer switch advice with thousands of helpful

Get Price

2021.5 / 2022 PLATEAU TS/FL

EXTERIOR 110-VOLT PLUG Located on the passenger side panel behind the rear wheel, this plug will only function if power is supplied through the inverter, generator or shore power. This

Get Price

Solved: Miller Effect

To resolve the Miller effect issue in your new design, you can implement the following strategies: 1. Use a gate driver with a fast turn-off time: Select a gate driver that can

Get Price

The performance of off-grid inverters in plateau areas

Inverters need to have a better insulation design, and the impact of high altitude on electrical performance can be reduced through material selection and structural design. The user

Get Price

Brand New 6.2kva 48v SMS Hybrid Inverter

Jiji ™ Original brand New 6.2kva 48v SMS hybrid inverter is very much available with affordable price, quality product and 5years warranty Contact with Young Miracle Global Link

Get Price

PLEASURE-WAY PLATEAU TS 2020 OWNER''S MANUAL Pdf

The inverter/charger provides 12 volt DC power inverted to 110-120 volt AC power for the microwave, entertainment center and all AC outlets in and outside the coach. Page 39:

Get Price

Estimating the chip temperature in an inverter by measuring the

Estimating the chip temperature in an inverter by measuring the temperature sensitive Miller plateau during turn-off Published in: PCIM Europe 2019; International Exhibition and

Get Price

PV Power Plateau

So that plateau is at the limit of the inverter. You will need to move about half the array to a separate solar charge controller to take advantage of all your solar panels capacity.

Get Price

The performance of off-grid inverters in plateau areas

Due to the unpredictable weather in plateau areas, inverters need to have strong anti-interference capabilities and be able to maintain a stable output current under various conditions of

Get Price

10kva 48volt Felicty Inverter in Jos

Lex Pen Solar Energy Enterprise > We have solar panels, inverters and Solar Street lights batteries of different sizes that can power either an entire building or selected appliances in the

Get Price

Power MOSFET Basics: Understanding Gate Charge and

Power MOSFET Basics: Understanding Gate Charge and Using it to Assess Switching Performance INTRODUCTION This note is part of a series of application notes that define the

Get Price

Solved: Miller Effect

To resolve the Miller effect issue in your new design, you can implement the following strategies: 1. Use a gate driver with a fast turn-off

Get Price

Estimation Technique for IGBT Module Junction

Power inverters are essential components that must be properly chosen and con- structed for reliable operation with heavy loads and various environmental conditions in high-power-density

Get Price

Microinverter reaching a plateau way below its nominal output power

This can be a variety of reasons including that the panels can''t produce any more or the inverter is maxed out. As an example, I see "peaks" when clouds come and go blocking

Get Price

6 FAQs about [Inverter power plateau]

What is a PV inverter?

2.1 Introduction PV inverters consist of multiple components , including power semiconductors, sensors, resistors, magnetics, control circuits, and auxiliary power supplies. All these components introduce some amount of power loss in the converter. Most of the time these losses dissipate as heat and lead to an increase in local temperature.

Do traction inverters reduce power losses?

Demand to reduce power losses will continue with the development of inverters that have higher power levels, especially as the number of motors per car increases, and trucks migrate to pure EV. Traction inverters have traditionally used insulated-gate bipolar transistors (IGBTs).

What are the specifications of a two-stage inverter?

Table 1. Specifications of the Two-Stage Inverter Input DC voltage 110 V Active power 1 kW Apparent power 1 kVA Output AC voltage 120 V RMS Output frequency 60 Hz DC-link voltage 220 V Input boost inductor 500 µH DC-link capacitor 1.35 mF Inverter LCL filter 1 mH, 24 µF, 0.2 mH Switching frequency 30 kHz

How can power system engineers improve traction inverter efficiency?

With increasing competition between electric vehicle (EV) manufacturers to develop models with lower cost and longer drive range, power system engineers are under pressure to reduce power losses and improve traction inverter system efficiency, which can improve driving ranges and provide a competitive advantage.

How is the lifetime of a PV inverter predicted?

Up to a certain point in time, the entire lifetime of a PV inverter was predicted based on the failure rates of individual components and handbooks provided by the manufacturers. In recent years, the prediction of the reliability and lifetime of power converters has been done through physics-of-failure assessments.

How much does an inverter cost?

As of 2017, the inverter and associated power conditioning components accounted for $0.15/W– $0.17/W of residential applications, significantly more than the U.S. Department of Energy (DOE) benchmark of $0.12/W by 2020.

More related information

-

Ultra-high power pulse inverter

Ultra-high power pulse inverter

-

Charging pile inverter power

Charging pile inverter power

-

Sun inverter high power

Sun inverter high power

-

Large inverter with high power

Large inverter with high power

-

Inverter power cost

Inverter power cost

-

Power emergency communication base station inverter grid-connected cost price

Power emergency communication base station inverter grid-connected cost price

-

Wind power generation connected to photovoltaic inverter

Wind power generation connected to photovoltaic inverter

-

Spanish power frequency off-grid inverter sales

Spanish power frequency off-grid inverter sales

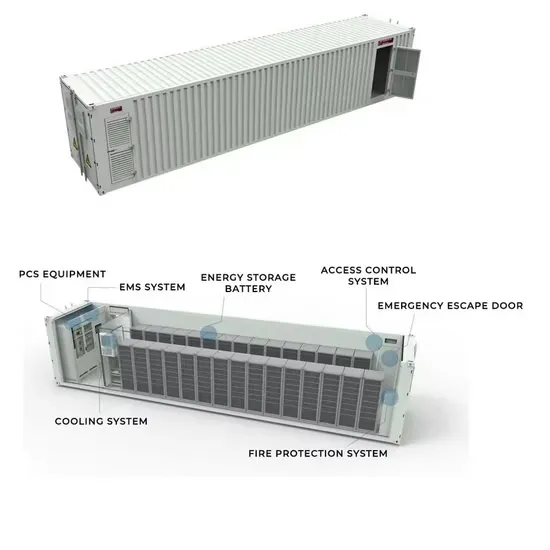

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.